Aqueous solution and powder agent of intense shale inhibitor for water-based drilling fluid as well as preparation method and inhibitor of aqueous solution and powder agent

A technology for water-based drilling fluid and shale inhibitor, which is applied in the field of potent shale inhibitor water agent, inhibitor, powder and preparation thereof for water-based drilling fluid, and can solve the problem of large field application restrictions, environmental pollution, formation pollution and other problems, to achieve the effect of excellent structural stability, convenient use and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

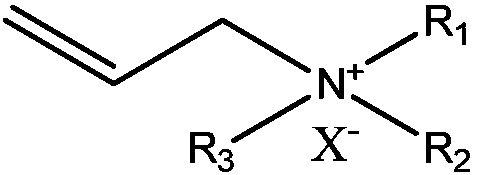

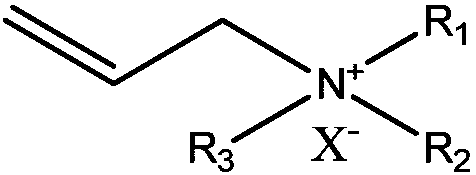

Method used

Image

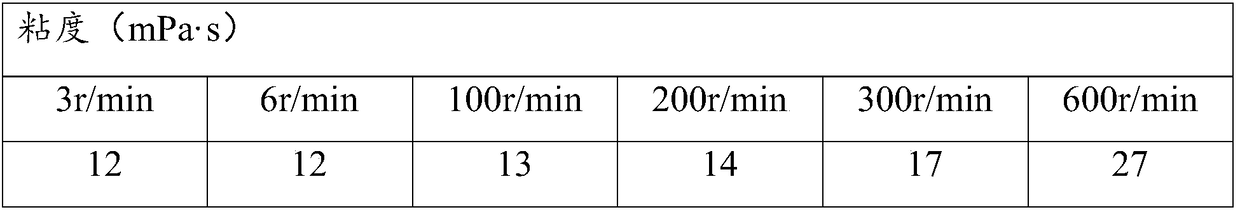

Examples

preparation example Construction

[0067] The preparation method of the powerful shale inhibitor water agent for water-based drilling fluid comprises the following steps:

[0068] S1: mixing and stirring the amine compound and the first solvent to obtain the first mixture;

[0069] S2: adding halogenated olefins to the obtained mixture to obtain a second mixture;

[0070] S3: Take part of the second mixture to determine whether the reaction is complete;

[0071] S4: After confirming that the reaction is complete, add water to the second mixture, stir and distill to obtain an aqueous solution. In some embodiments, the S1 includes the following components in parts by mass:

[0072] Amine compounds: 20-50 parts

[0073] The first solvent: 2 to 10 parts.

[0074] In some embodiments, the S2 includes the following components in parts by mass: halogenated olefins: 15-30 parts.

[0075] In some embodiments, the S3 includes the following steps:

[0076] S31: Mix 200mL of dichloromethane and 100mL of anhydrous met...

Embodiment 1

[0106] ① Add 20 parts of amine compounds composed of N,N-dimethylethanolamine and N,N-dimethylpropanolamine, and 2 parts of the first solvent composed of methanol and ethanol into the reaction kettle at room temperature middle;

[0107] The ratio of N,N-dimethylethanolamine to N,N-dimethylpropanolamine is 2:1;

[0108] The ratio of methanol to ethanol is 2:1;

[0109] ②Stir in an oil bath at 50°C for 30 minutes until evenly mixed;

[0110] ③ Slowly add 15 parts of halogenated olefin formed by the combination of allyl chloride and allyl bromide into the reaction kettle dropwise, and keep the reaction temperature at 50°C during the dropwise addition;

[0111] The ratio of allyl chloride to allyl bromide is 2:1;

[0112] After the dropwise addition is completed, raise the temperature to 60°C to continue the reaction for 3 hours, and then sample and dilute;

[0113] ④ Add 200mL of dichloromethane and 100mL of anhydrous methanol into a 500mL glass bottle and mix well as a devel...

Embodiment 2

[0122] ① Combining 50 parts of amine compounds composed of N-methyldiethanolamine, triethanolamine, dodecyldiethanolamine, hexadecyldiethanolamine, octadecyldiethanolamine with acetone, isopropanol, ethylene glycol 10 parts of the first solvent formed by the combination of alcohols are added to the reaction kettle at room temperature;

[0123] The ratio of N-methyldiethanolamine, triethanolamine, dodecyldiethanolamine, hexadecyldiethanolamine and octadecyldiethanolamine is 3; 3:3:3:1;

[0124] ②Stir in an oil bath at 50°C for 30 minutes until evenly mixed;

[0125] ③ Slowly add 30 parts of allyl iodide into the reaction kettle dropwise, and keep the reaction temperature at 50°C during the dropwise addition;

[0126] After the dropwise addition is completed, raise the temperature to 60°C to continue the reaction for 3 hours, and then sample and dilute;

[0127] ④ Add 200mL of dichloromethane and 100mL of anhydrous methanol into a 500mL glass bottle and mix well as a developer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com