Metallurgy sintering resource utilizing method for waste incineration fly ash, city sludge and steel and iron metallurgy dust removing ash

A technology for waste incineration fly ash and iron and steel metallurgy, which is applied in the field of waste resource utilization, and can solve the problems of sinter quality impact, deterioration of sinter gas permeability, and impact on sinter production technical indicators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

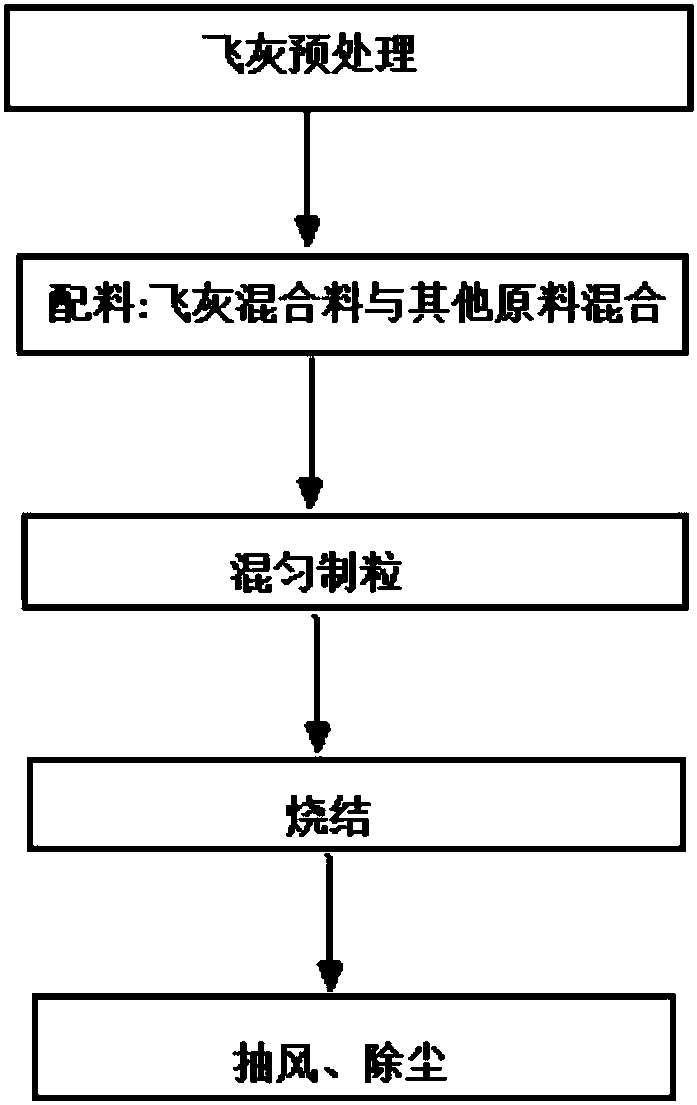

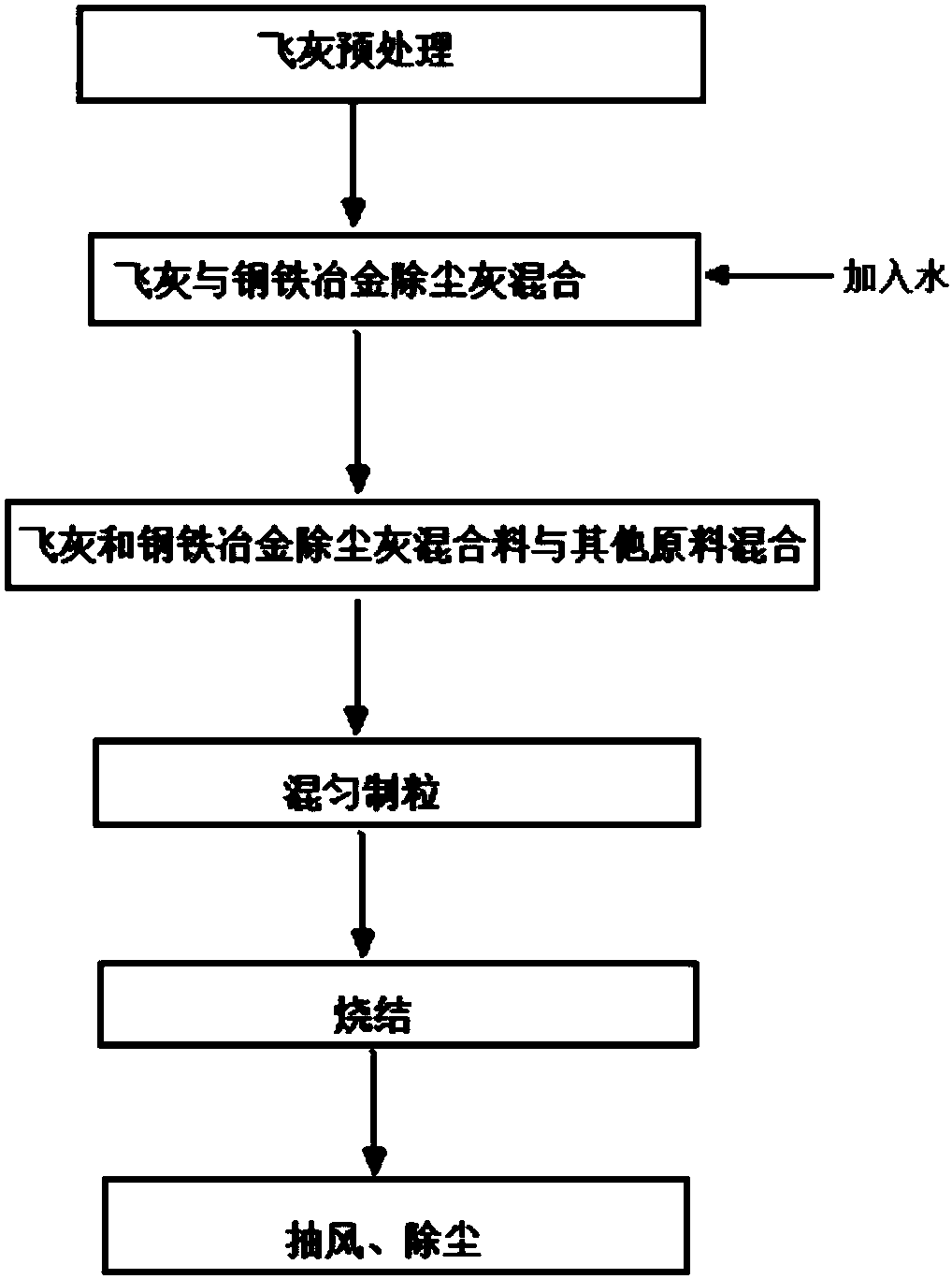

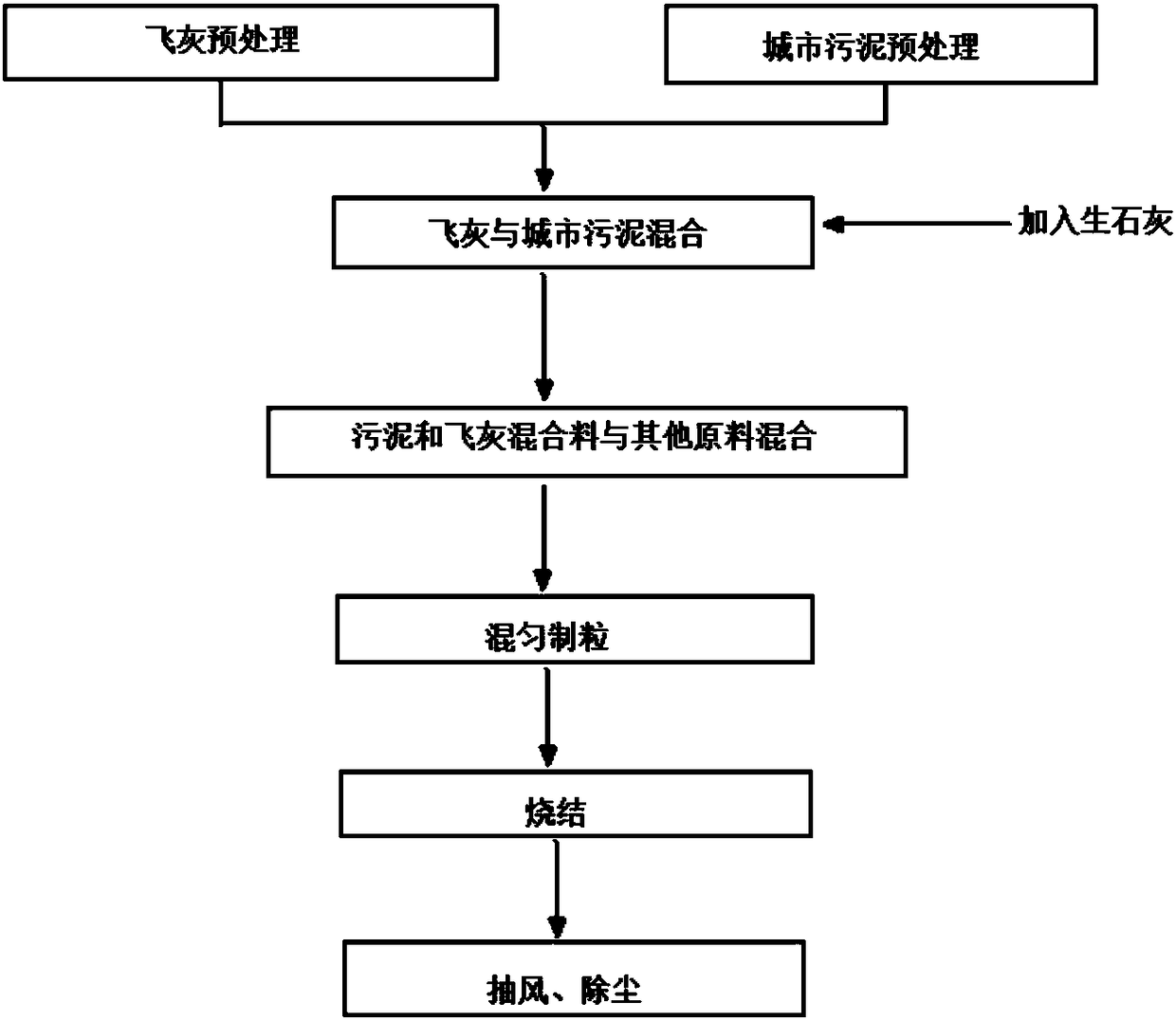

[0101] According to the first embodiment provided by the present invention, a resource utilization method of waste incineration fly ash metallurgical sintering is provided.

[0102] A method for resource utilization of waste incineration fly ash metallurgical sintering, the method comprises the following steps:

[0103] (A1) Fly ash pretreatment step: Stir and mix the waste incineration fly ash and binder evenly to obtain a fly ash mixture;

[0104] (B1) batching step: mixing the obtained fly ash mixture with sintering raw materials to obtain primary sintering mixture, wherein the sintering raw materials include iron-containing raw materials for sintering, flux and fuel;

[0105] (C) Mixing and granulation step: the sintered mixture is mixed by the first mixer (that is, the first mixing) and the optional second mixer (that is, the second mixing) to obtain granular or pelletized sintered mixture. Homogenization;

[0106] (D) Sintering step: putting the sintered mixed material...

Embodiment 1

[0172] A method for resource utilization of waste incineration fly ash metallurgical sintering, the method comprises the following steps:

[0173] (A1) Fly ash pretreatment step: stirring and mixing the waste incineration fly ash and bentonite as a binder evenly to obtain a fly ash mixture; wherein: the mixing ratio of the waste incineration fly ash and the binder is 4:1 (weight Compare);

[0174] (B1) Dosing step: Mix 6 parts by weight of the obtained fly ash mixture with 194 parts by weight of sintering raw material to obtain a primary sintering mixture, wherein the sintering raw material includes 67wt% iron ore powder for sintering, 26wt% Flux (1:1 weight ratio of dolomite and limestone) and 7wt% anthracite coal powder; wherein: the amount of fly ash mixture is 3wt%, and the weight percentage is based on the total weight of the sintered ingredients;

[0175] (C) Mixing and granulating step: the sintered mixture is mixed by the first mixer (ie, first mixing) and second mixe...

Embodiment 2

[0179] Repeat embodiment 1, just this method also comprises:

[0180] (E) exhausting step: the smoke produced by sintering is sucked away by the exhaust fan through the bellows under the sintering machine trolley;

[0181] (F) Dust removal step: the exhaust fan passes the flue gas through the electrostatic precipitator to remove dust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com