Atom dispersion water oxidation catalyst and preparation and application thereof

An atomic dispersion and water oxidation technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. The effect of low preparation cost, good catalytic stability and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 40mg of manganese nitrate, 0.5g of graphene oxide and 100mL of water were sonicated in a 250mL beaker for 4 hours, then stirred at room temperature for 4 hours to mix well, and then the mixture was dried in air at 80°C. Finally, the obtained solid was ground into powder, and calcined at 700° C. for 4 hours in ammonia gas to obtain a black powder. Stir the obtained black powder in 5mol / L nitric acid solution at 80°C for one hour, filter, wash with water, and dry at 80°C, which is the catalyst with dispersed manganese atoms (Mn-G). The content of manganese in the catalyst is about 0.1%. The properties are shown in Table 1.

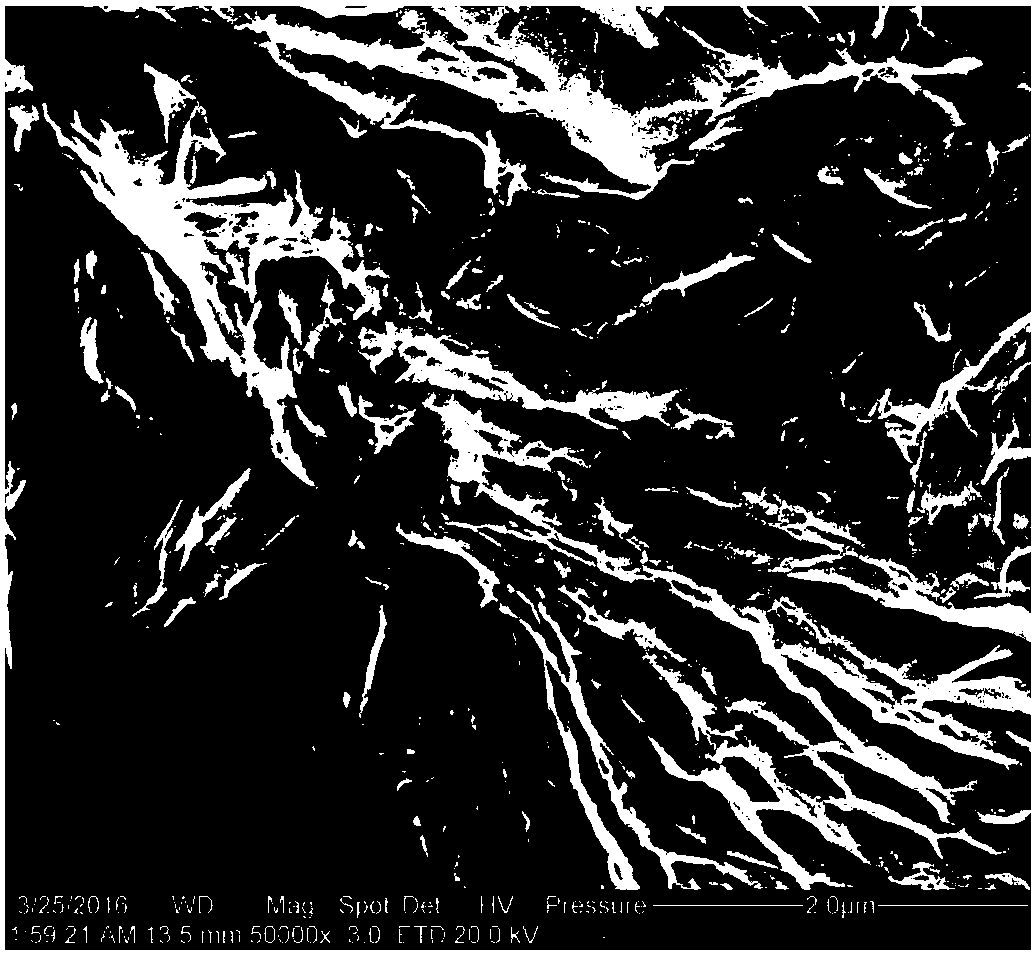

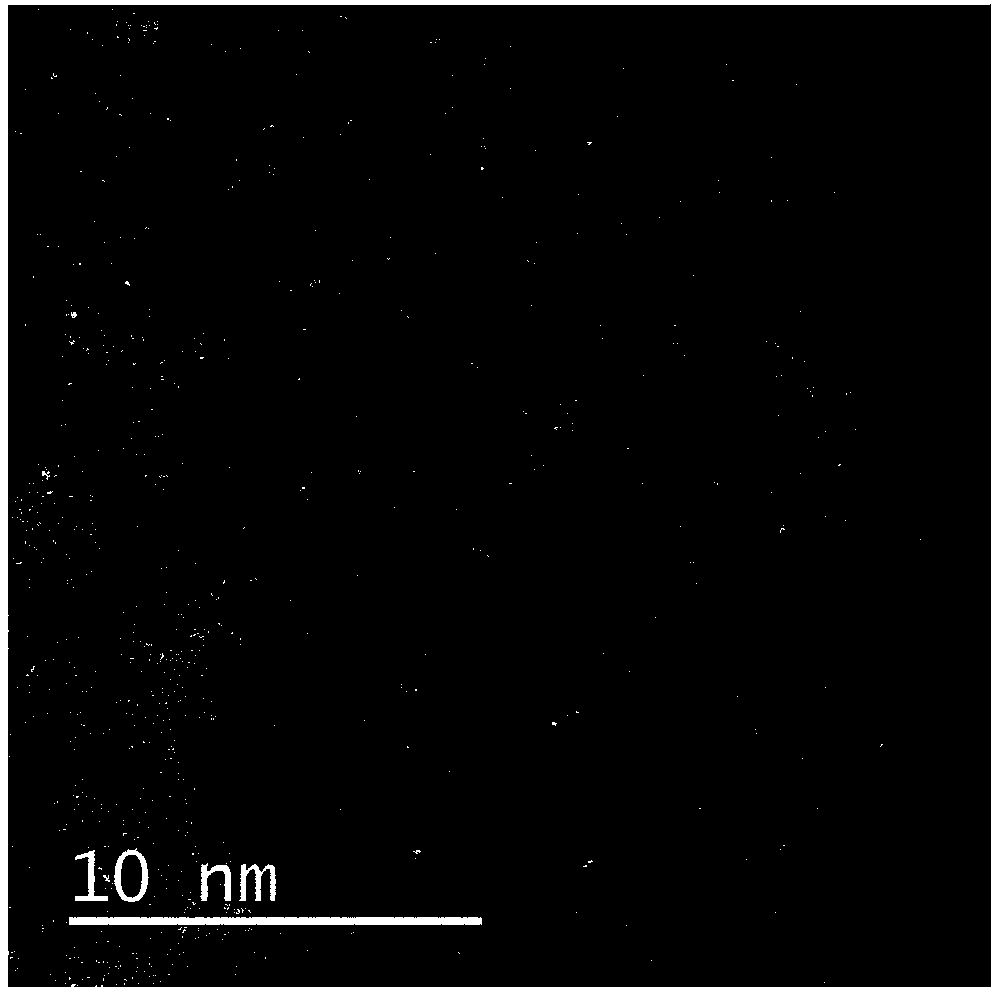

[0038] from Figure 1 to Figure 3 In the scanning and projection and spherical aberration transmission electron microscope given in , it can be found that the metal manganese in the catalyst we synthesized is mainly dispersed in the graphene framework at the atomic level.

Embodiment 2

[0040] 40mg of ferric nitrate, 0.5g of graphene oxide and 100mL of water were sonicated in a 250mL beaker for 4 hours, then stirred at room temperature for 4 hours to mix well, and then the mixture was dried in air at 80°C. Finally, the obtained solid was ground into powder, and calcined at 500° C. for 4 hours in ammonia gas to obtain a black powder. The obtained black powder was stirred in 5 mol / L nitric acid solution at 80°C for one hour, filtered, washed with water, and dried at 80°C to obtain a catalyst with dispersed iron atoms (Fe-G). performance see Figure 8 .

Embodiment 3

[0042] 40mg of nickel nitrate, 0.5g of graphene oxide and 100mL of water were sonicated in a 250mL beaker for 4 hours, then stirred at room temperature for 4 hours to mix well, and then the mixture was dried in air at 80°C. Finally, the obtained solid was ground into powder, and calcined at 500° C. for 4 hours in ammonia gas to obtain a black powder. The obtained black powder was stirred in 5 mol / L nitric acid solution at 80°C for one hour, filtered, washed with water, and dried at 80°C to obtain a nickel atom-dispersed catalyst (Ni-G). performance see Figure 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com