Preparation method of ethanediamine dihydroiodide and application to feed additive

A technology of ethylenediamine dihydroiodide and ethylenediamine, which is applied in application, animal feed, additional food elements, etc., can solve problems such as potential safety hazards, high price of hydriodic acid, poor purity, etc., and save environmental protection input costs. , avoid environmental pollution, increase the effect of iodine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A 1L small high-pressure reactor is selected as the main reactor, which consists of a kettle cover, a kettle body, a strong magnetic coupling stirrer, a high temperature and high pressure needle valve, a pressure instrument, a lower stirring part, an internal cooling coil, a temperature measuring part, a liquid pipe, etc. System Components.

[0035] This reaction is to generate hydrogen iodide on the surface of the catalyst through hydrogen and iodine under the action of the catalyst, and the hydrogen iodide is neutralized with ethylenediamine acid base to obtain ethylenediamine dihydroiodide.

[0036] Steps:

[0037] (1) Install the reaction instrument, add 50g of iodine elemental substance, 9.67g of ethylenediamine (theoretical calculation value), and 0.25g of platinum black catalyst into a 1L small-scale high-pressure reactor; Therefore, the quality of ethylenediamine actually dropped into the reactor is greater than 9.67g.

[0038] (2) Control the temperature of t...

Embodiment 1

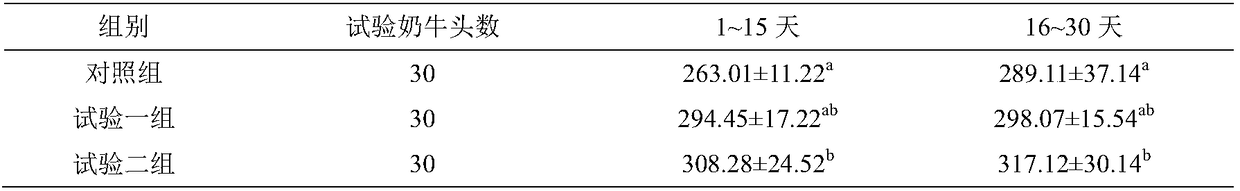

[0052] Table 1 shows the test results of ethylenediamine dihydroiodine on the milk production performance of lactating dairy cows in Example 1. The result of table 1 shows, from the milk yield of lactating cow during 1-15 days, add 2.0mg / kg ethylenediamine dihydroiodine than control group high 17.20%, and add 2.0mg / kg potassium iodide group Milk production increased by 4.70%; From the perspective of milk production of lactating cows during the 16-30 days, adding 2.0mg / kg ethylenediamine dihydroiodide increased by 9.70% compared with the control group, while adding 2.0mg / kg The milk yield of the potassium iodide group has increased by 6.40%; combined with the milk production performance of 1-15 days and 16-30 days, it is shown that the ethylenediamine dihydrogen iodide prepared by this embodiment can effectively improve the milk production of lactating cows than potassium iodide quantity.

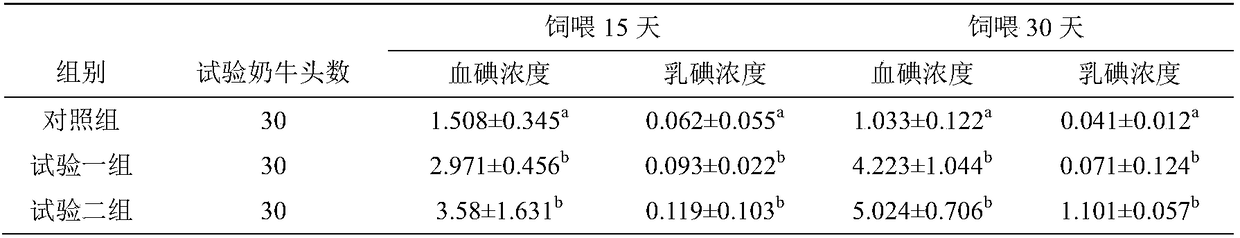

[0053] Table 2 Effects of ethylenediamine dihydroiodide on blood iodine and milk iodine...

Embodiment 2

[0060] A 1L small high-pressure reactor is selected as the main reactor, which consists of a kettle cover, a kettle body, a strong magnetic coupling stirrer, a high temperature and high pressure needle valve, a pressure instrument, a lower stirring part, an internal cooling coil, a temperature measuring part, a liquid pipe, etc. System Components.

[0061] This reaction is that hydrogen and iodine generate hydrogen iodide on the surface of the catalyst under the action of the catalyst, and the hydrogen iodide is neutralized with ethylenediamine acid and alkali to obtain ethylenediamine dihydroiodide.

[0062] Steps:

[0063] (1) Install the reaction instrument, add 50g of iodine elemental substance, 9.67g of ethylenediamine (theoretical calculation value) and 0.4g of platinum black catalyst into a 1L small-scale high-pressure reactor; Therefore, the quality of ethylenediamine actually dropped into the reactor is greater than 9.67g.

[0064] (2) Control the temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com