Nano-hydroxyapatite/polyhexamethylene monoguanidine hydrochloride/silica gel composite material preparation method and solid-phase extraction method

A technology of polyhexamethylene monoguanidine hydrochloride and nano-hydroxyapatite, which is applied to the preparation of nano-hydroxyapatite/polyhexamethylene monoguanidine hydrochloride/silica gel composite materials, solid phase extraction of traces in water In the field of quantitative Cr, it can solve the problems of low mechanical strength, small particle size of nanomaterials, and large flow resistance, and achieve the effects of non-toxic and harmless raw materials, high adsorption efficiency, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of nano-hydroxyapatite / polyhexamethylene monoguanidine hydrochloride / silica gel composite material comprises the following specific steps:

[0026] (1) Weigh 6.0g of silica gel with a particle size of 80-100 mesh and put it into a 100mL beaker, add 60mL of 2.5mol / L nitric acid solution, stir for 30 minutes, seal, soak for 16 hours, filter, and wash with deionized water until neutral , Dry at 150°C for 4 hours.

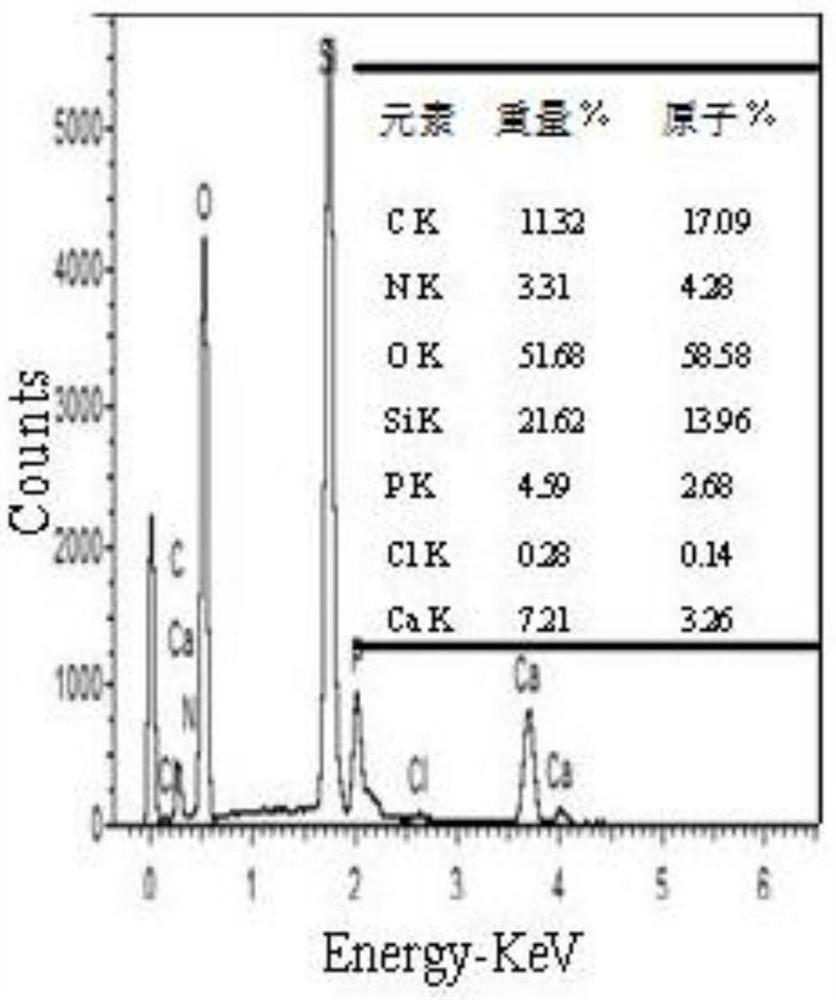

[0027] (2) Weigh 80.0 mg of activated silica gel into a 10 mL centrifuge tube, add 10 mL of polyhexamethylene monoguanidine hydrochloride solution with an average molecular weight of about 2000 and a concentration of 1.0%, shake well, and ultrasonically shake for 10 minutes, then add 16.0 mg of nano-hydroxyapatite with a particle size of 20-50nm, that is, the mass ratio of nano-hydroxyapatite to silica gel is 1:5, shake well, and then ultrasonically vibrate for 10 minutes, centrifuge for 20 minutes (centrifuge rotation speed 10000 rpm / mi...

Embodiment 2

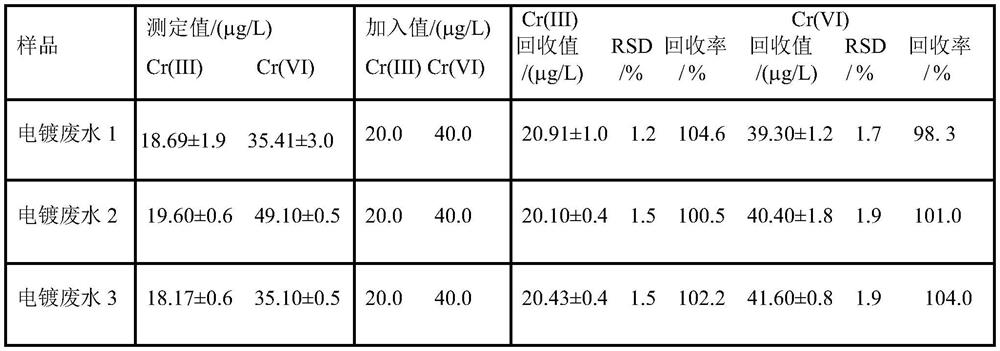

[0029] Take 20 mg of the composite material prepared in Example 1 and put it into a self-made micro-enrichment column. The micro-enrichment column has an inner diameter of 2.0 mm and a polytetrafluoroethylene tube with a length of 4.0 cm. Connect a peristaltic pump to adjust the pH of the water sample to 4.0. At a sampling flow rate of 3.5mL / min, 40mL of water samples were enriched, and then eluted with 1mL 8% (v / v) nitric acid solution at an elution flow rate of 6.5mL / min, and the eluate was analyzed by atomic absorption spectrometry Measure with a photometer and record the absorbance value. The standard curve method was used to determine the content of Cr(Ⅵ) in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com