Method for treating boron-containing wastewater in 6-hydroxyl-8-chloro ethyl caprylate preparation process

A treatment method and waste water technology, applied in the direction of neutralized water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve problems such as inability to form recycling, few application fields of potassium metaborate, and difficulties in market sales, etc., to achieve Avoid the direct discharge of waste water, easy to recycle, and the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

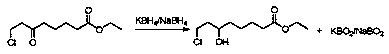

Image

Examples

Embodiment 1

[0022] Dissolve 100Kg of ethyl 6-oxo-8-chlorooctanoate in 500Kg of dichloroethane, add 1kg of tetrabutylammonium bromide, add potassium borohydride ammonia solution dropwise below 35°C (16kg potassium borohydride+48g17% ammonia water ), control the internal temperature below 35°C, and keep warm for 3 hours. The organic layer was washed with water to neutrality, concentrated under reduced pressure at 0.1MPa, until the temperature was 110°C, and 95kg of 6-hydroxy-8-chlorooctanoic acid ethyl ester concentrate with a content of 91% was obtained.

[0023] Recover 35kg of 10% ammonia water in the water phase at 100°C, add 32kg of water, add 30% hydrochloric acid dropwise at 50-55°C, until pH 1, keep warm for 3 hours, filter to obtain 18Kg of boric acid, dry at 80°C to obtain 15Kg, with a purity of 99.2%. After filtering boric acid, distill 20kg of water from the solution, cool to 10°C, and keep warm for 2 hours to obtain 14.8Kg of potassium chloride by filtration, and dry at 90°C to...

Embodiment 2

[0025] Dissolve 100Kg of ethyl 6-oxo-8-chlorooctanoate in 500Kg of dichloroethane, add 1kg of tetrabutylammonium bromide, add potassium borohydride ammonia solution (16kg potassium borohydride+48kg17% ammonia water) dropwise below 35°C ), control the internal temperature below 35°C, and keep warm for 3 hours. The organic layer was washed with water to neutrality, concentrated under reduced pressure at 0.1MPa until the temperature reached 110°C, and 96kg of concentrated solution of 6-hydroxy-8-chlorooctanoic acid ethyl ester with a content of 92% was obtained.

[0026] Recover 30kg of 10% ammonia water in the water layer at 100°C, add 48kg of water, add 30% hydrochloric acid dropwise at 50-55°C to pH 2, keep warm for 2.5 hours, filter to obtain 18.4Kg of boric acid, and dry at 80°C to obtain 16Kg with a purity of 99.6%. After filtering the boric acid, distill 36kg of water from the solution, cool to 20°C, and keep warm for 2 hours to obtain 17.2Kg of potassium chloride by filtr...

Embodiment 3

[0028] Dissolve 100Kg of ethyl 6-oxo-8-chlorooctanoate in 500Kg of dichloroethane, add 1kg of tetrabutylammonium bromide, add potassium borohydride ammonia solution (16kg potassium borohydride+48kg17% ammonia water) dropwise below 35°C ), control the internal temperature below 35°C, and keep warm for 3 hours. The organic layer was washed with water to neutrality, concentrated under reduced pressure at 0.1MPa, until the temperature was 110°C, and 95kg of 6-hydroxy-8-chlorooctanoic acid ethyl ester concentrate with a content of 93% was obtained.

[0029] Recover 32kg of 10% ammonia water in the water layer at 100°C, add 40kg of water, add 30% hydrochloric acid dropwise at 50-55°C to pH 1.5, keep warm for 3 hours, filter to obtain 18Kg of boric acid, and dry at 80°C to obtain 15.6Kg with a purity of 99.8%. After filtering the boric acid, the solution was combined with 40 kg of potassium chloride mother liquor of Example 2, steamed off 48 kg of water, cooled to 15° C., kept warm f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com