Bio-based film-forming resin and photoresist prepared by same

A film-forming resin and bio-based technology, applied in the field of functional polymer materials, can solve the problems of affecting the edge roughness of the resin and reducing the free volume of the polymer chain, so as to achieve good product application performance, improve solubility, polymer molecular weight and The effect of strong distribution controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

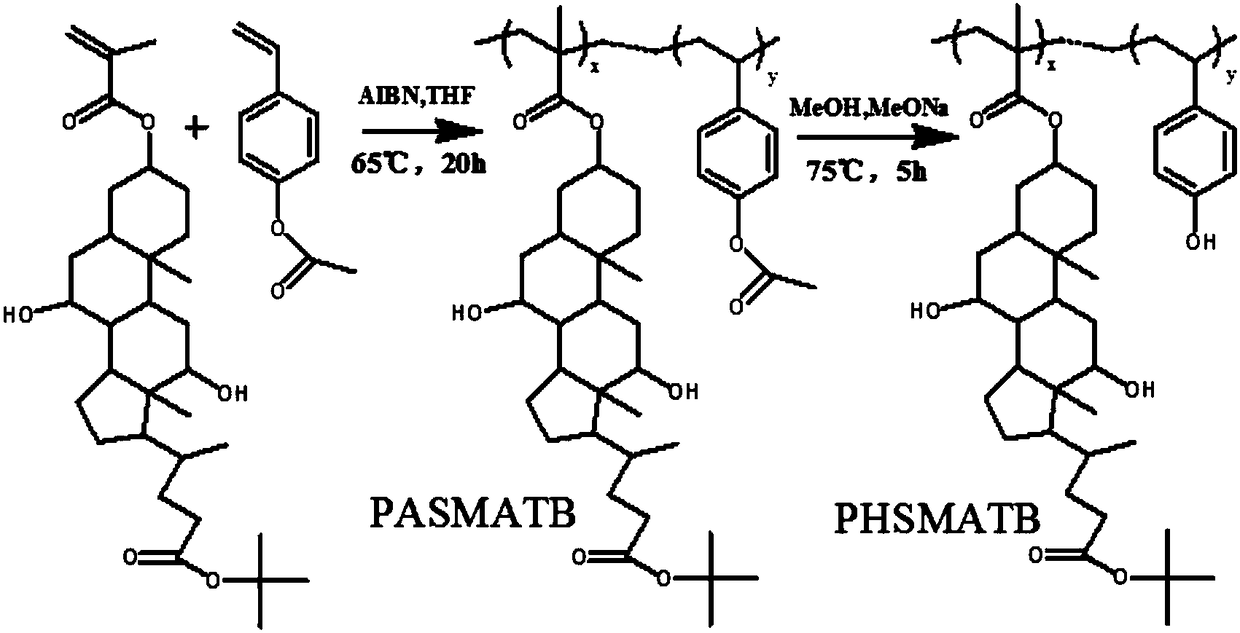

[0037] A bio-based film-forming resin is prepared through the following steps:

[0038] (1) Take a clean three-neck bottle, install the reflux and condensation device, add 1.68g of acetoxystyrene (ASM), 1.9g of tert-butyl methacrylate cholate (MATBCE), 0.14g of AIBN and 15g of THF, and pass N 2 Protection for 5 minutes;

[0039] (2) Put the three-neck flask in an oil bath at 65°C for 20 hours to obtain the intermediate product PASMATB-1;

[0040] (3) Subsequently, 10 g of THF was distilled off, 0.9 g of sodium methoxide and 20 ml of methanol were added, the temperature was raised to 75° C., alcoholysis was carried out for 6 hours, and the reaction was completed to obtain the final product PHSMATB-1;

[0041] (4) Using methanol as a solvent and water as a precipitant, the resulting product was repeatedly dissolved, purified with water three times, and the precipitate was dried in a vacuum oven at 60° C. to obtain a white solid, namely the bio-based film-forming resin. Accordi...

Embodiment 2

[0043] A bio-based film-forming resin is prepared through the following steps:

[0044] (1) Take a clean three-necked bottle, install the reflux and condensation device, add 1.12g of acetoxystyrene (ASM), 3.8g of tert-butyl methacrylate cholate (MATBCE), 0.14g of AIBN and 15g of THF, and pass N 2 Protection for 5 minutes;

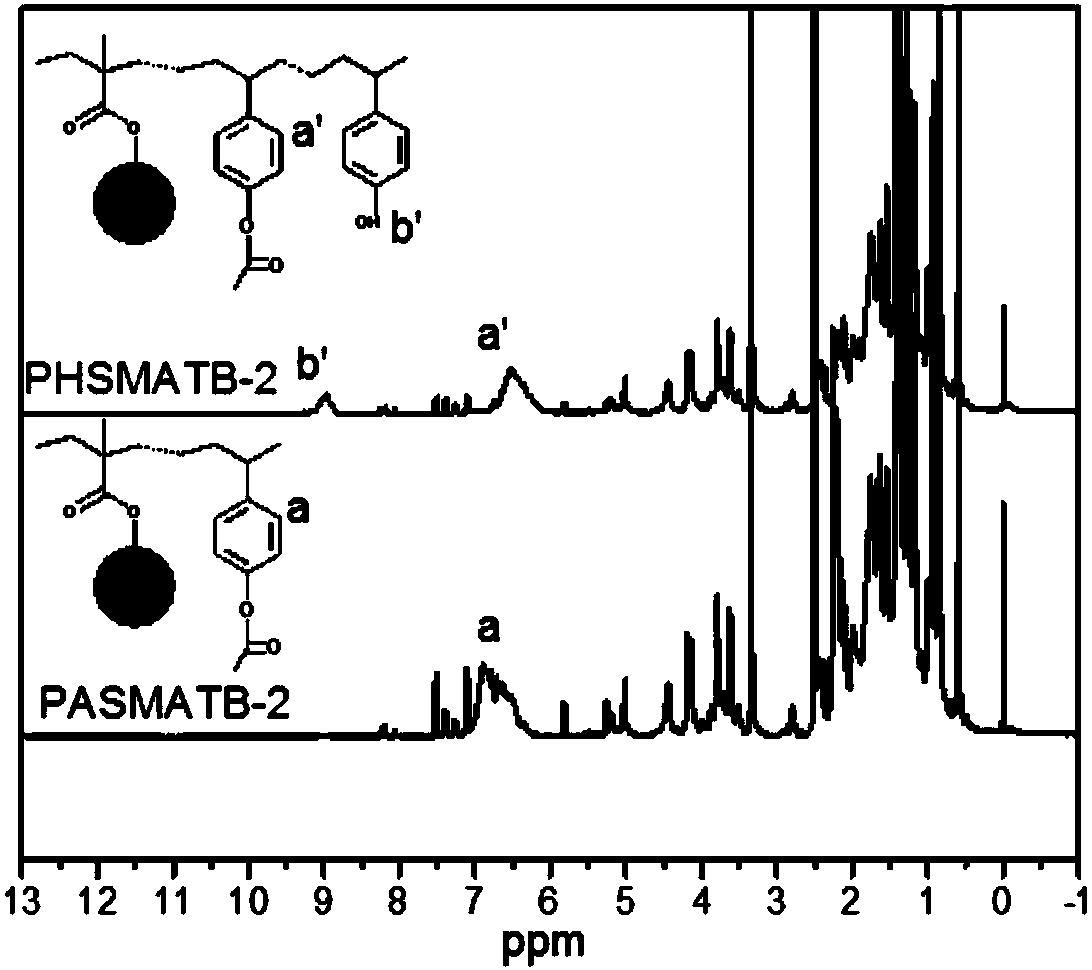

[0045] (2) Put the three-necked flask in a 65°C oil bath for 20 hours to obtain the intermediate product PASMATB-2;

[0046] (3) Then 10 g of THF was distilled off, 0.6 g of sodium methoxide and 20 ml of methanol were added, the temperature was raised to 75 ° C, alcoholysis was carried out for 6 h, and the reaction was completed to obtain the final product PHSMATB-2;

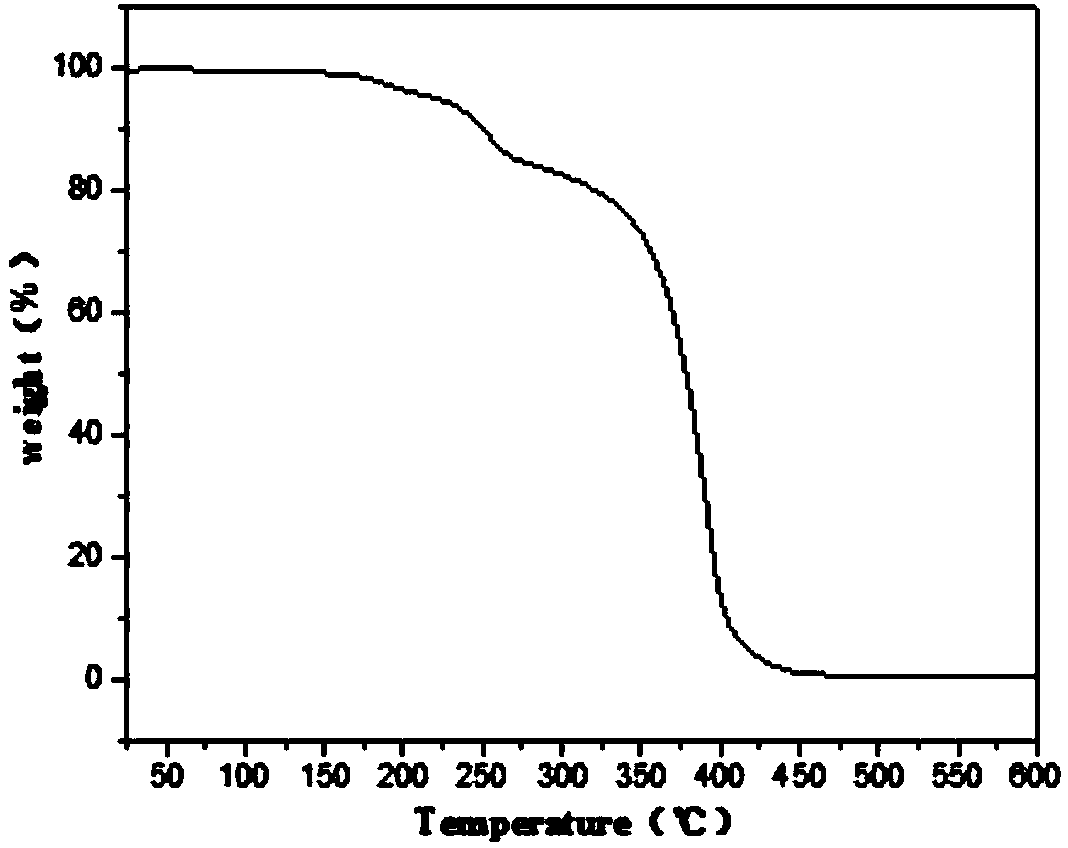

[0047] (4) Using methanol as a solvent and water as a precipitant, the resulting product was repeatedly dissolved, purified with water three times, and the precipitate was dried in a vacuum oven at 60° C. to obtain a white solid, namely the bio-based film-forming resin. According to the GPC...

Embodiment 3

[0052] A bio-based film-forming resin is prepared through the following steps:

[0053] (1) Take a clean three-necked bottle, install the reflux and condensation device, add 0.56g of acetoxystyrene (ASM), 5.7g of tert-butyl methacrylate cholate (MATBCE), 0.14g of AIBN and 15g of THF, and pass N 2 Protection for 5 minutes;

[0054] (2) Place the three-neck flask in an oil bath at 65°C for 20 hours to obtain the intermediate product PASMATB-3;

[0055] (3) Subsequently, 10 g of THF was distilled off, 0.3 g of sodium methoxide and 20 ml of methanol were added, the temperature was raised to 75° C., alcoholysis was carried out for 6 h, and the reaction was completed to obtain the final product PHSMATB-3;

[0056] (4) Using methanol as a solvent and water as a precipitant, the resulting product was repeatedly dissolved, purified with water three times, and the precipitate was dried in a vacuum oven at 60° C. to obtain a white solid, namely the bio-based film-forming resin. Accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com