Method for preparing grooved anode Schottky diode

A technology of Schottky diodes and anodes, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as reducing turn-on voltage and reverse leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

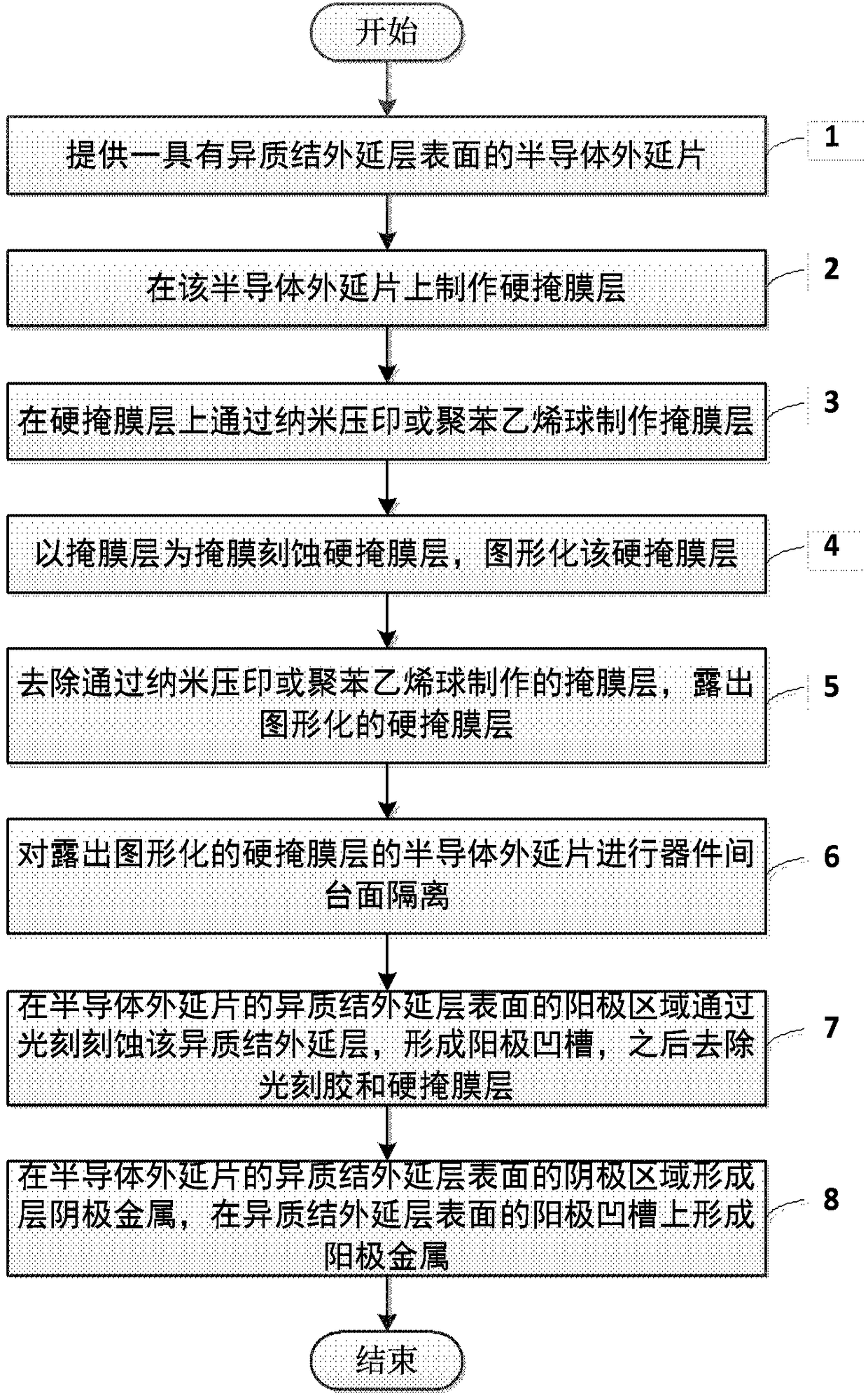

[0010] Such as figure 1 As shown, the preparation method of the recessed anode Schottky diode provided by the present invention comprises the following steps:

[0011] Step 1: Provide a semiconductor epitaxial wafer with a heterojunction epitaxial layer surface; the semiconductor epitaxial wafer can be a gallium nitride-based heterojunction epitaxial wafer, a gallium arsenide-based heterojunction epitaxial wafer, or silicon carbide with lateral conductivity epitaxial wafers, but not limited thereto.

[0012] Step 2: making a hard mask layer on the semiconductor epitaxial wafer; the hard mask layer is a material having an etching ratio with the semiconductor epitaxial wafer, including materials such as silicon dioxide, silicon nitride, nickel or gold.

[0013] Step 3: Make a mask layer by nanoimprinting or polystyrene spheres on the hard mask layer; the mask layer made by nanoimprinting or polystyrene spheres on the hard mask layer is made of nanoimprint Compared with the nan...

Embodiment 1

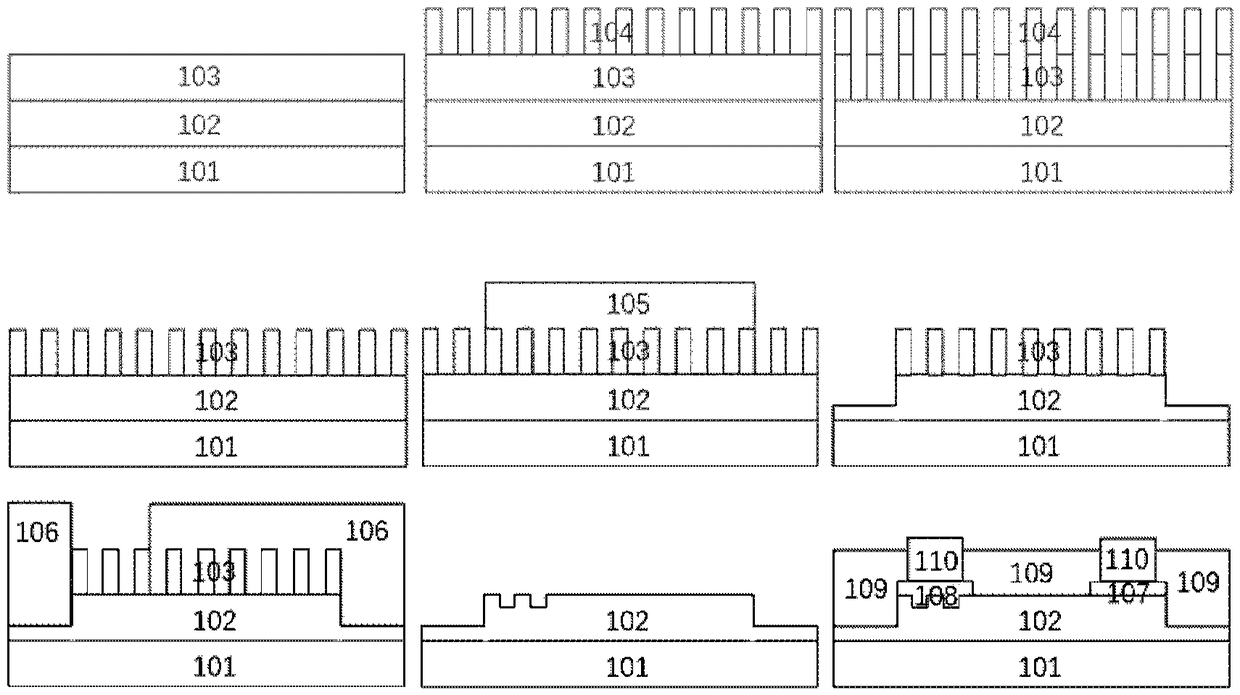

[0022] figure 2 It is a flow chart of the preparation process of an AlGaN / GaN heterojunction recessed anode Schottky diode using a sapphire substrate according to an embodiment of the present invention. The method includes the following steps:

[0023] Step 21: providing an epitaxial wafer, the epitaxial wafer is grown on the substrate 101 of sapphire material, and the AlGaN / GaN heterojunction epitaxial layer 102 is grown by MOCVD;

[0024] Step 22: On the epitaxial wafer, use PECVD equipment to deposit SiO 2 as a hard mask layer 103;

[0025] Step 23: On the hard mask layer 103, make a mask layer 104 by nanoimprinting technology;

[0026] Step 24: Using the mask layer 104 as a mask, use ICP equipment to etch the SiO in the hard mask layer 103 2 , to pattern the hard mask layer 103;

[0027] Step 25: using sulfuric acid hydrogen peroxide to remove the mask layer 104;

[0028] Step 26: Spread the glue and expose on the patterned hard mask layer 103 to form a mesa mask 105...

Embodiment 2

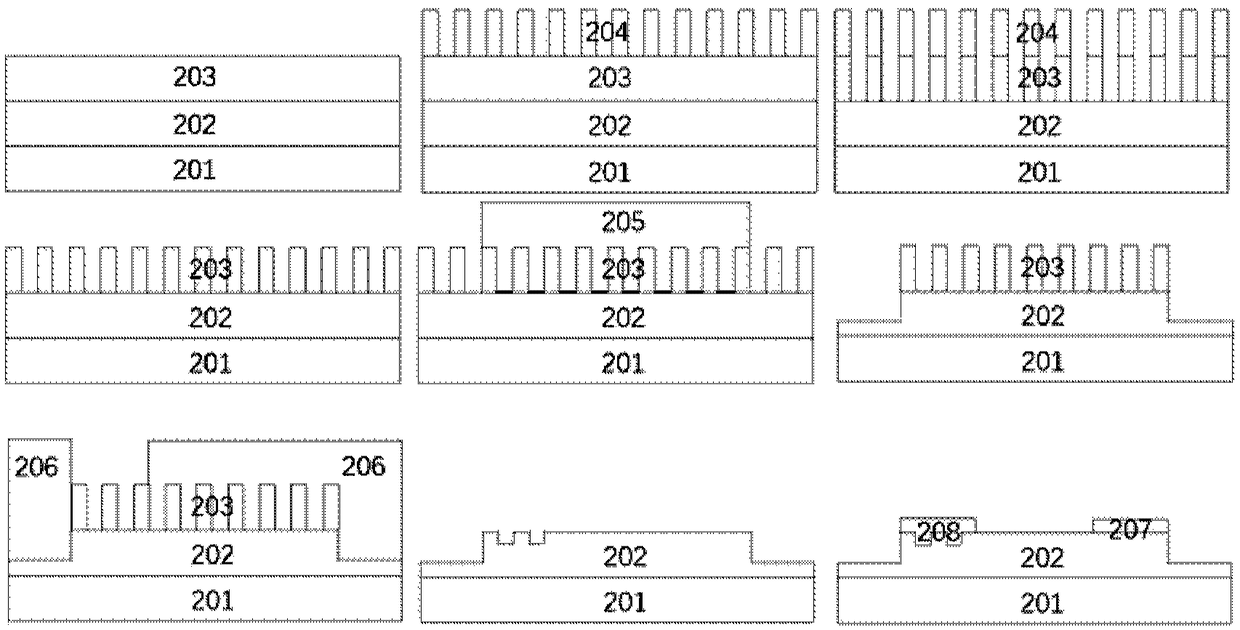

[0033] image 3 It is a flow chart of the preparation process of an InAlN / GaN heterojunction recessed anode Schottky diode using a silicon substrate according to an embodiment of the present invention. The method includes the following steps:

[0034] Step 31: providing an epitaxial wafer, the epitaxial wafer is grown on the substrate 201 of silicon material, and the InAlN / GaN heterojunction epitaxial layer 202 is grown by MOCVD;

[0035] Step 32: on the epitaxial wafer, use PECVD equipment to deposit SiNx as the hard mask layer 203;

[0036] Step 33: Fabricate a mask layer 204 on the hard mask layer 203 by nanoimprinting technology;

[0037] Step 34: Using the mask layer 204 as a mask, use ICP equipment to etch the SiNx in the hard mask layer 203 to pattern the hard mask layer 203;

[0038] Step 35: using sulfuric acid hydrogen peroxide to remove the mask layer 204;

[0039] Step 36: Spread the glue and expose on the patterned hard mask layer 203 to form a mesa mask 205, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com