Loach suction pumping equipment with adjustable water absorbing amount

A water absorption and adjustable technology, applied in fishing, application, animal husbandry, etc., can solve the problems of time-consuming and labor-intensive salvage, high difficulty coefficient of catching, etc., and achieve the effects of low manufacturing cost, expanding the extraction range and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

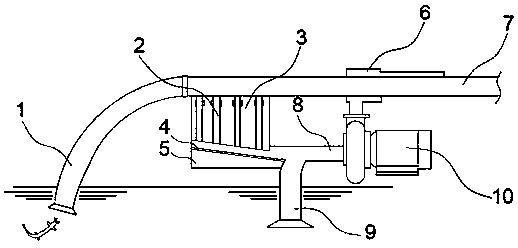

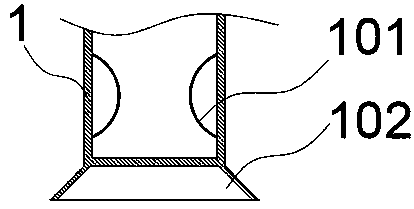

[0014] Such as figure 1 As shown, the suction loach pump equipment that can adjust the water absorption includes a ceramic tube 7, an ejector 6 connected to the ceramic tube 7, a liquid suction pump 10 connected below the ejector 6, and a liquid suction pipe 8 is provided on the side of the liquid suction pump 10 , the suction pipe 8 is connected with the suction branch pipe 9 placed below the water surface, the water inlet of the suction branch pipe 9 is provided with a sediment separation net, the water inlet of the ceramic tube 7 is connected with the suction pipe 1 placed below the water surface, and the liquid suction method is used to The loach is extracted above the loach breeding pond. When the loach does not hide in the bottom of the mud, it can effectively and quickly extract the loach, and the damage to the loach is small. Use the liquid suction pump 10 to directly extract the water in the cultivation pond from the direction of the outlet of the ejector 6 , forming ...

Embodiment 2

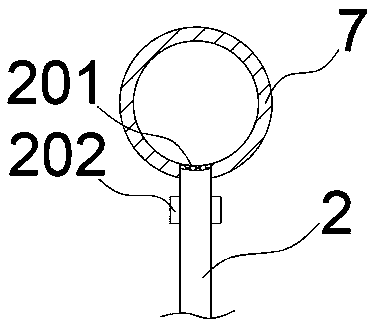

[0016] This embodiment is further optimized on the basis of implementation 1: as Figure 1-3 As shown, a filter box 3 is arranged between the jet 6 and the water inlet of the ceramic tube 7, the filter box 3 is vertically connected to the pipe wall below the ceramic tube 7, the bottom of the filter box 3 is connected to the pumping pipe 8, and the bottom of the filter box 3 is provided with Inclined filter plate 4, the top of the filter plate 4 is provided with a filter tube 2 vertically connected to the pipe wall below the ceramic tube 7, a filter screen 201 is provided at the connection between the filter tube 2 and the ceramic tube 7, the filter tube 2 is an elastic material, and the filter tube 2 The outer arms on both sides are equipped with electromagnets 202, and the bottom of the filter plate 4 and the filter box 3 form a sediment collection chamber 5. In the initial stage of sucking loach, in order to maintain the negative pressure in the ceramic tube 7, the filter tub...

Embodiment 3

[0018] The straw 1 of the present invention is a rubber tube consisting of the following components and parts by weight: 20-45 parts of chlorohydrin rubber, 3-7 parts of carbon black, 2,2,4-trimethyl-1,2-dihydroquinoline polymerized 0.3-0.5 parts of N, N'-diphenyl-p-phenylenediamine, 3-5 parts of titanium dioxide, 2-3 parts of antimony trioxide, 2-5 parts of ethylene vinyl acetate copolymer, 4-5 parts of decabromodiphenylethane, 3-4 parts of calcium hydroxide, 0.1-0.2 parts of diallyl disulfide, 7-13 parts of polyvinyl silicone oil, 0.5-1 part of stearic acid, talcum powder 8-12 parts, 2-5 parts of silicon dioxide, 0.3-0.8 parts of magnesium oxide; the rubber tube preparation steps are as follows: 1) Put the raw materials in the rubber tube formula into the internal mixer, and add 0.3 parts of accelerator, pass Synthesize rubber with internal mixer, filter and test to obtain rubber with hardness of 72±5 Hs, tensile strength ≥ 9MPa, and elongation ≥ 250%; 2) Put the rubber in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com