Electrochemical oxidation method and device for calcium sulfite in flue gas desulfurization ash

A calcium sulfite and oxidation device technology, applied in the direction of electrolysis, electrolysis components, cells, etc., can solve the problems of large fluctuations in composition and complex composition, and achieve the effects of improving service life, reducing corrosion, and promoting oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The flue gas desulfurization ash comes from the sintering flue gas semi-dry method desulfurization ash of the iron and steel plant, and sampling is carried out, and the calcium sulfite in the desulfurization ash is measured by iodometric method to be 27.20wt%.

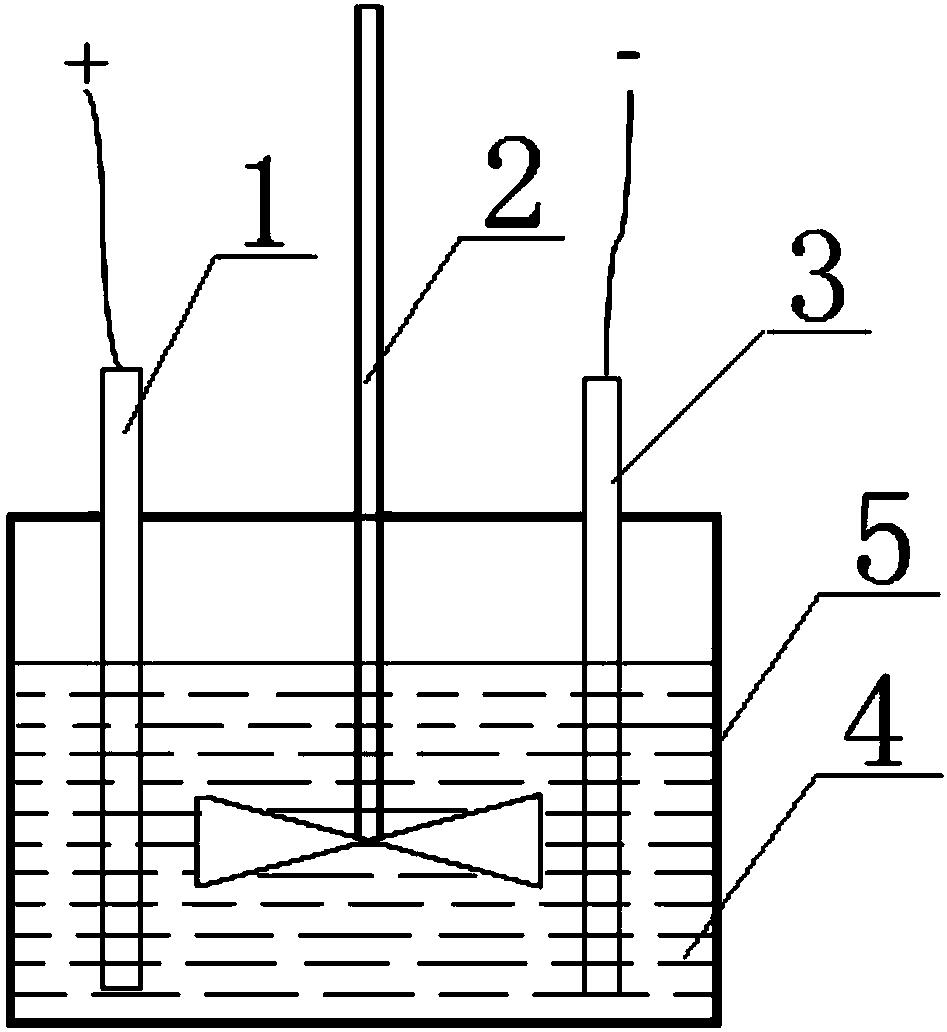

[0050] Weigh 5.0g of flue gas desulfurization ash and put it into electrolytic cell 5, add 250ml of water (the ratio of water to material is 50:1), stir with paddle 2 at a speed of 100rpm; submerge inert anode 1 and inert cathode 3 into the smoke In the gas desulfurization ash slurry 4, the paddle 2 is used to stir at a speed of 300rpm, and 1-3 drops of ammonia water are added dropwise. Through the buffering effect of ammonia water, the ionization continuously releases hydroxide ions, supplements the hydroxide ions near the anode and ensures The pH of the slurry does not change much during the reaction, and the ammonium ion produced by ionization has weak oxidation and will not react at the cathode. At the same t...

Embodiment 2

[0052] The flue gas desulfurization ash comes from the flue gas desulfurization ash of the sintering flue gas semi-dry process factory of the iron and steel plant. The sampling is carried out, and the calcium sulfite in the desulfurization ash is measured by the iodometric method to be 26.50wt%.

[0053] Weigh 6.25g of flue gas desulfurization ash and put it into the electrolytic cell 5, add 250ml of water (the ratio of water to material is 40:1), stir with paddle 2 at a speed of 200rpm; In the gas desulfurization ash slurry 4, the paddle 2 is used to stir at a speed of 200rpm; a direct current with a voltage of 25V is passed through, and the current density is 101.61A / m 2 After 30 minutes, the remaining calcium sulfite content in the system was measured to be 12.11wt%, and the oxidation efficiency of calcium sulfite in the flue gas desulfurization ash was 54.3%.

Embodiment 3

[0055] The flue gas desulfurization ash comes from the flue gas desulfurization ash of the sintering flue gas semi-dry process factory of the iron and steel plant, and is sampled, and the calcium sulfite in the desulfurization ash is measured by the iodometric method to be 20.35wt%.

[0056] Weigh 4.2g of flue gas desulfurization ash and put it into the electrolytic cell 5, add 250ml of water (the ratio of water to material is 60:1), stir with paddle 2 at a speed of 100rpm; submerge the inert anode 1 and inert cathode 3 In the gas desulfurization ash slurry 4, the paddle 2 is used to stir at a speed of 100rpm; a direct current with a voltage of 26V is passed through, and the current density is 103.69A / m 2 After 45 minutes, the remaining calcium sulfite content in the system was measured to be 5.66wt%, and the oxidation efficiency of calcium sulfite in the flue gas desulfurization ash was obtained to be 72.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation efficiency | aaaaa | aaaaa |

| oxidation efficiency | aaaaa | aaaaa |

| oxidation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com