Construction method of circulating water glass fiber reinforced plastic pipeline

A pipeline construction and glass fiber reinforced plastic technology, which is applied in water conservancy projects, pipeline connection layout, pipeline laying and maintenance, etc., can solve the installation specification requirements of large-diameter circulating water glass fiber reinforced plastic pipelines, affecting the laying and operation of large-diameter glass fiber reinforced plastic pipelines, internal leakage, etc. problems, to achieve the effect of meticulous and rigorous construction plan, good promotion and practicality, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

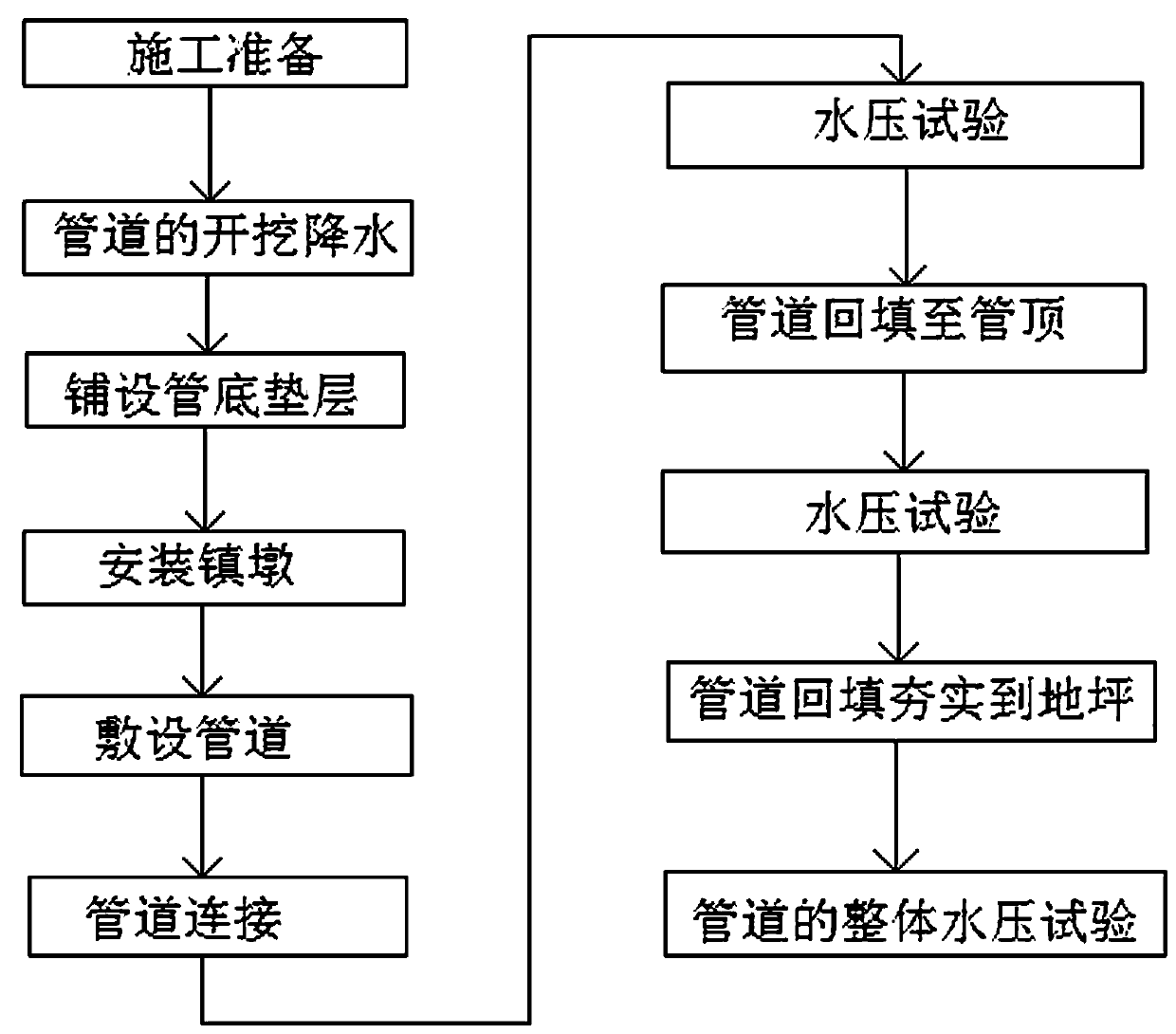

[0024] Embodiment: a kind of circulating water glass fiber reinforced plastic pipeline construction method, comprises the following steps:

[0025] (1) Construction preparation: preparation of basic materials;

[0026] (2) Pipeline excavation and precipitation: slope the pipeline according to the soil conditions, reserve 600mm gaps on both sides, use a spirit level to level the pipe bottom ditch bed, and lay sandbags on both sides; When the groundwater level is -2 meters, it is necessary to drill a dewatering well according to the situation. When the ground is exposed, a small drainage ditch is installed on both sides of the pipeline for drainage.

[0027] (3) Pipeline installation: Lay the pipe bottom cushion at the bottom of the pipe, install the pier, lay the pipe after installation, and finally connect the pipe, and conduct a hydraulic test after the pipe is connected;

[0028] (4) Backfilling of pipelines: Backfill the pipelines immediately after the pipeline connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com