Aluminum matrix composite, and preparation method of aluminum matrix composite based on 3D (three dimensional) printing

An aluminum-based composite material and 3D printing technology, which is applied in the direction of manufacturing tools, additive processing, ceramic products, etc., can solve the problems of limited product size, long process flow, complicated process, etc., and achieve simple process, short process program, Solve the effect of long process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

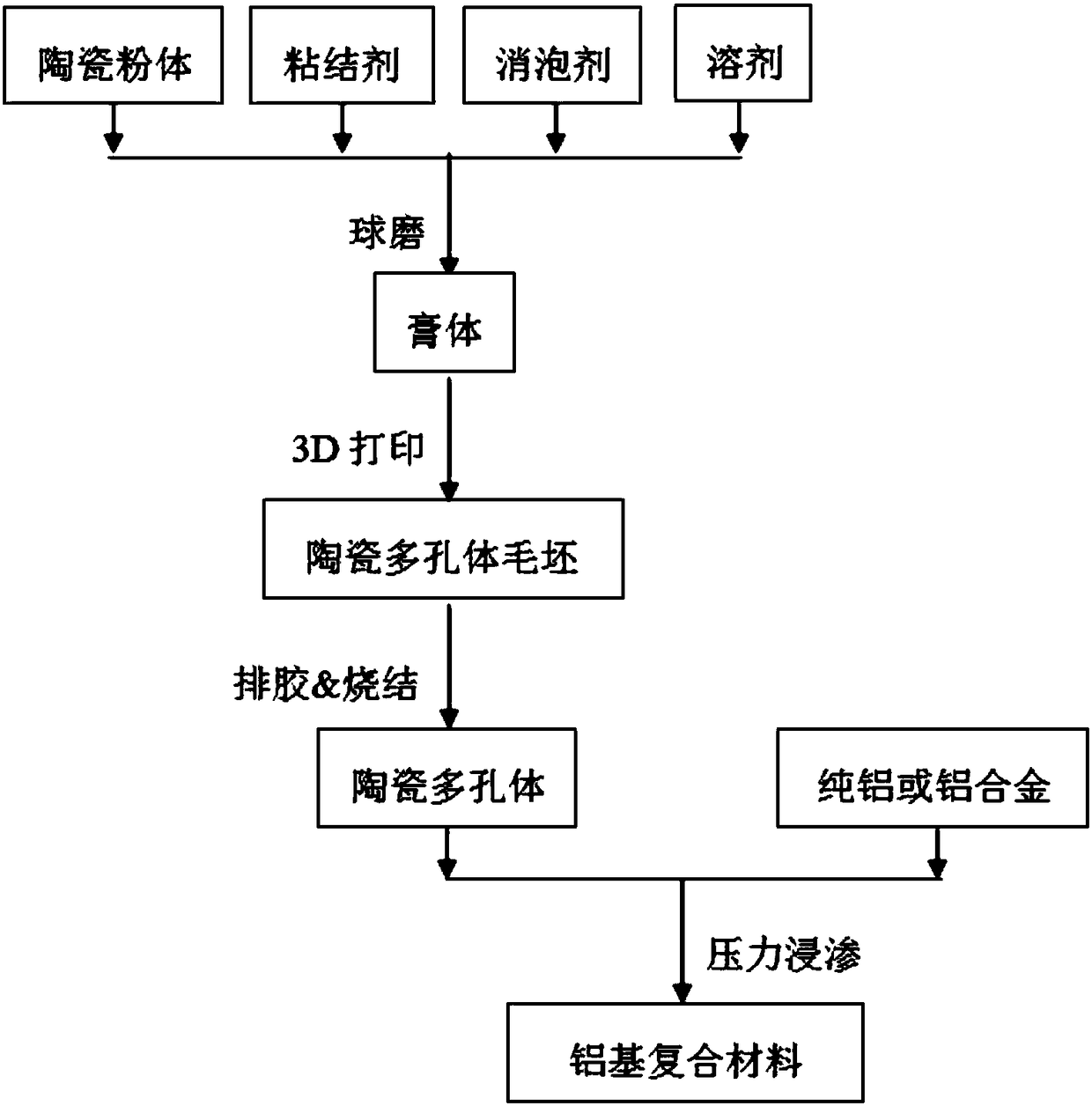

[0027] figure 1 Schematic flow chart of the preparation process of the aluminum matrix composite material provided for the embodiment of the invention. see figure 1 , an embodiment of the present invention provides a method for preparing a 3D-printed aluminum-based composite material, including:

[0028] The step of preparing ceramic porous body blank by 3D printing: put the pre-prepared ceramic paste for 3D printing into the silo of the 3D printer, and prepare the ceramic porous body blank for aluminum matrix composite material by nozzle extrusion forming technology;

[0029] The solidification and sintering steps of the ceramic porous body blank: the formed aluminum matrix composite material is solidified with the ceramic porous body blank, and then the integrated degreasing and sintering treatment is carried out in the air furnace to obtain the ceramic porous body for the aluminum matrix composite material. body;

[0030] Steps for preparing aluminum matrix composites by...

Embodiment 1

[0058] This embodiment provides an aluminum matrix composite material, which is mainly prepared by the following preparation method of aluminum matrix composite material based on 3D printing:

[0059] S1 3D printing preparation of ceramic porous body blank: accurately weigh 140g of silicon carbide powder with a particle size of 10μm, 25g of water glass, 5g of epoxy resin, 2g of ethylene glycol, 2g of n-butanol, 2g of polydimethylsiloxane, Put 20g of ionized water and 4g of glycerin into a ball mill jar, then ball mill on a planetary ball mill at a speed of 300 rpm for 3 hours, and mix evenly to obtain a silicon carbide ceramic paste for 3D printing; then the prepared The paste is loaded into the silo of the 3D desktop printer, and the silicon carbide ceramic porous body blank of the design specification is formed by 3D printing technology;

[0060] Steps of solidification and sintering of S2 ceramic porous body blank: place the formed silicon oxide ceramic porous body blank in...

Embodiment 2

[0063] This embodiment provides an aluminum matrix composite material, which is mainly prepared by the following preparation method of aluminum matrix composite material based on 3D printing:

[0064] S1 3D printing preparation of ceramic porous body blanks: accurately weigh 140g of alumina powder with a particle size of 50μm, 26g of water glass, 2g of ethylene glycol, 2g of n-butanol, 20g of deionized water and 10g of ethanol, put them into a ball mill jar, and then Mill on a planetary ball mill at a speed of 350 revolutions per minute for 2 hours, and mix evenly to obtain an alumina ceramic paste for 3D printing; then put the prepared paste into the hopper of a 3D desktop printer, and use 3D printing technology to form Alumina ceramic porous body blank with design specifications;

[0065] S2 Solidification and sintering steps of the ceramic porous body blank: place the formed zirconia ceramic porous body blank in a carbon dioxide atmosphere for 2 minutes, dry and solidify; f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com