Method of reducing cadmium volatilization in process of preparing biological carbon from straw

A technology of biochar and straw, applied in the field of environmental engineering, to reduce the volatilization of cadmium, facilitate the adsorption and stabilization of cadmium, and increase the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment provides a method for preparing biochar from straw, the specific steps are as follows:

[0019] Clean the rapeseed stalks, put them in an oven to dry at 60°C, crush the dried stalks with a pulverizer, weigh 10 g of the crushed stalks and place them in a clean quartz boat, and then place the quartz boat in a tube furnace (usually into high-purity nitrogen) for firing, the temperature is set at 300°C, 350°C, 400°C, 450°C, 500°C, 550°C, the time is set at 2 hours, and the absorbing liquid is 0.1mol / L hydrochloric acid, which is used to absorb smoke gas.

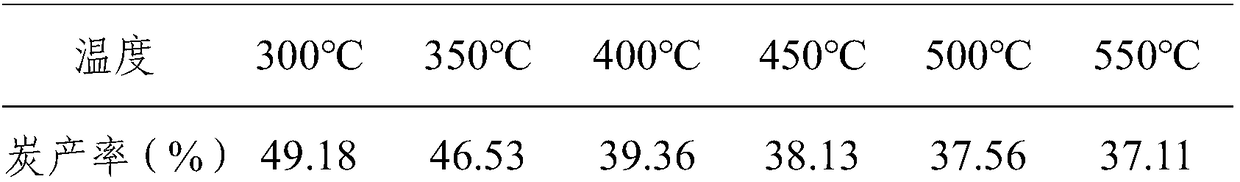

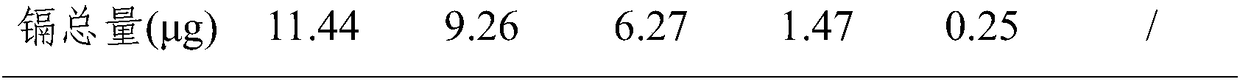

[0020] After the firing is completed, take out the quartz boat and place it in a drying oven to cool to room temperature, weigh and calculate the carbon yield, and use HCl-HNO 3 -HF-HClO 4 Digest, measure the cadmium content with ICP emission spectrometer (ICPMA8300, Perkinelmer), the obtained results are shown in the table below:

[0021] Table 1 The change of carbon yield and total cadmium with temper...

Embodiment 2

[0026] This embodiment provides a method for preparing biochar from straw, the specific steps are as follows:

[0027] Clean the rapeseed stalks, put them in an oven for drying at 60°C, crush the dried stalks with a pulverizer until they can pass through a 14-mesh sieve, weigh 10g of the crushed stalks and mix them with 0.5g of ferric sulfate, and place them in a clean quartz boat , and then put the quartz boat in a tube furnace (introduced with high-purity nitrogen) for firing, set the temperature at 300°C, set the time for 2 hours, and the absorbing liquid was 0.1mol / L hydrochloric acid.

[0028] After the firing was completed, the quartz boat was taken out and placed in a drying oven to cool to room temperature. The total amount of cadmium was detected to be 11.97 μg, and the specific surface area of biochar was 0.199 m 2 / mg, the calculated Cd fixation rate is 90%.

Embodiment 3

[0030] This embodiment provides a method for preparing biochar from straw, the specific steps are as follows:

[0031] Clean the rapeseed stalks, put them in an oven to dry at 60°C, crush the dried stalks with a pulverizer until they can pass through a 14-mesh sieve, weigh 10g of the crushed straws and mix them with 0.5g of ferric chloride, and place them in a clean quartz Then place the quartz boat in a tube furnace (introduced with high-purity nitrogen) for firing, set the temperature at 300°C, set the time for 2 hours, and the absorbing liquid is 0.1mol / L hydrochloric acid.

[0032] After the firing was completed, the quartz boat was taken out and placed in a drying oven to cool to room temperature. The total amount of cadmium was detected to be 12.58 μg, and the specific surface area of biochar was 0.22 m 2 / mg, the calculated Cd fixation rate was 94.59%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com