Implant active surface

An active surface and implant technology, applied in surface reactive electrolytic coating, prosthesis, liquid chemical plating, etc., can solve problems such as implant failure, and achieve the effect of increasing roughness, mild preparation conditions, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

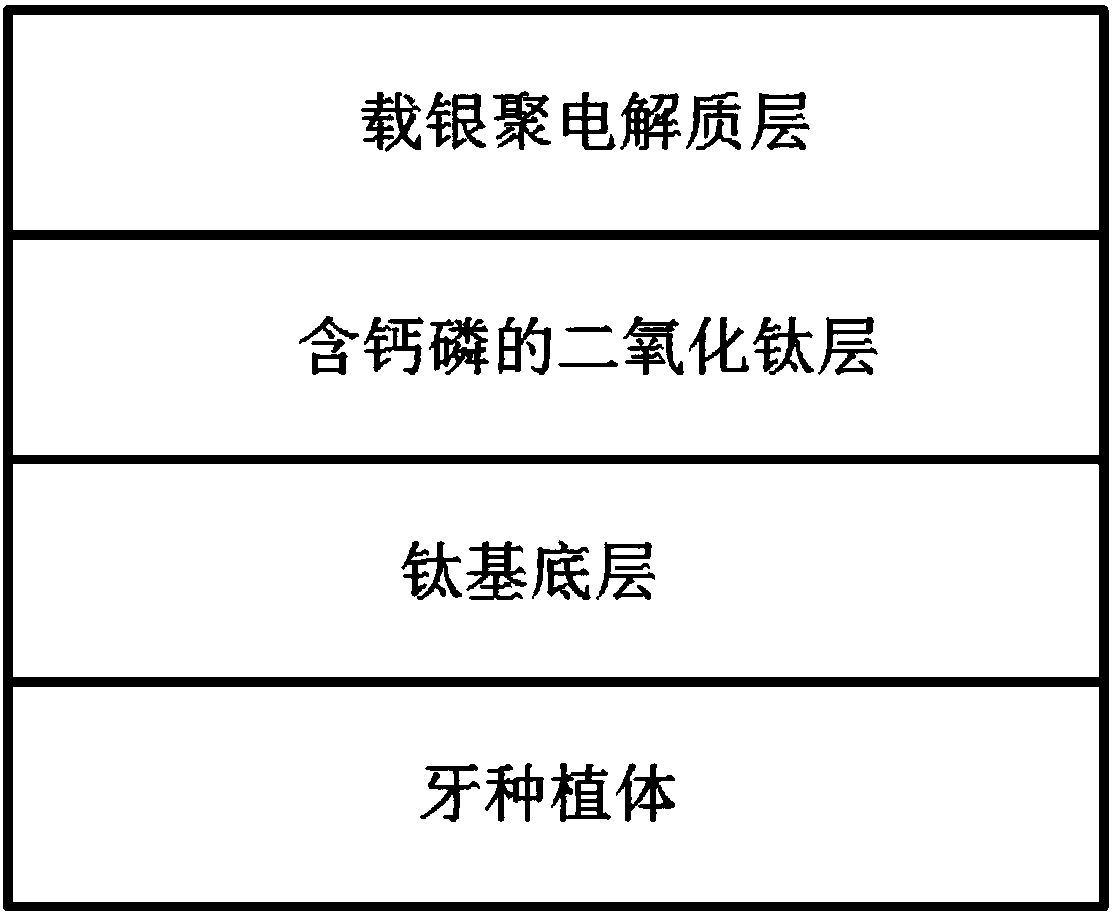

[0034] An implant active surface, the surface of the implant has a titanium base layer, the outer surface of the titanium base layer is coated with a titanium dioxide layer containing calcium and phosphorus, and the outer surface of the titanium dioxide layer containing calcium and phosphorus is coated with A polyelectrolyte layer, the polyelectrolyte layer is composed of positively charged polylysine and negatively charged hyaluronic acid, the polyelectrolyte layer is loaded with silver to obtain a silver-loaded polyelectrolyte layer, which is prepared according to the following method:

[0035] (1) The surface of the TA4 industrial pure titanium implant was polished step by step with 200, 300, 600, 1200 and 2000 mesh sandpaper, followed by ultrasonic cleaning with acetone, ethanol and distilled water for 10 minutes, and dried to form a titanium base layer;

[0036] (2) Place the implant in step (1) in a mixed etching agent composed of hydrofluoric acid and hydrochloric acid f...

Embodiment 2

[0045] An implant active surface, the surface of the implant has a titanium base layer, the outer surface of the titanium base layer is coated with a titanium dioxide layer containing calcium and phosphorus, and the outer surface of the titanium dioxide layer containing calcium and phosphorus is coated with A polyelectrolyte layer, the polyelectrolyte layer is composed of positively charged polylysine and negatively charged hyaluronic acid, the polyelectrolyte layer is loaded with silver to obtain a silver-loaded polyelectrolyte layer, which is prepared according to the following method:

[0046] (1) The surface of the TA2 industrial pure titanium implant was polished step by step with 200, 300, 600, 1200 and 2000 mesh sandpaper, followed by ultrasonic cleaning with acetone, ethanol and distilled water for 10 minutes, and dried to form a titanium base layer;

[0047] (2) Place the implant in step (1) in a mixed etching agent composed of hydrofluoric acid and hydrochloric acid f...

Embodiment 3

[0056] An implant active surface, the surface of the implant has a titanium base layer, the outer surface of the titanium base layer is coated with a titanium dioxide layer containing calcium and phosphorus, and the outer surface of the titanium dioxide layer containing calcium and phosphorus is coated with A polyelectrolyte layer, the polyelectrolyte layer is composed of positively charged polylysine and negatively charged hyaluronic acid, the polyelectrolyte layer is loaded with silver to obtain a silver-loaded polyelectrolyte layer, which is prepared according to the following method:

[0057] (1) The surface of the TC4 titanium alloy implant was polished step by step with 200, 300, 600, 1200 and 2000 mesh sandpaper, followed by ultrasonic cleaning with acetone, ethanol and distilled water for 10 minutes, and dried to form a titanium base layer;

[0058] (2) Place the implant in step (1) in a mixed etching agent composed of hydrofluoric acid and hydrochloric acid for surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com