Bioactivity glass porous bone repair material and preparation method thereof

A bioactive glass and bone prosthetic technology, applied in prosthetics, tissue regeneration, medical science, etc., can solve the problems of not being widely used in clinical practice, and achieve the advantages of cell adhesion and proliferation, easy access to raw materials, and easy process parameters The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

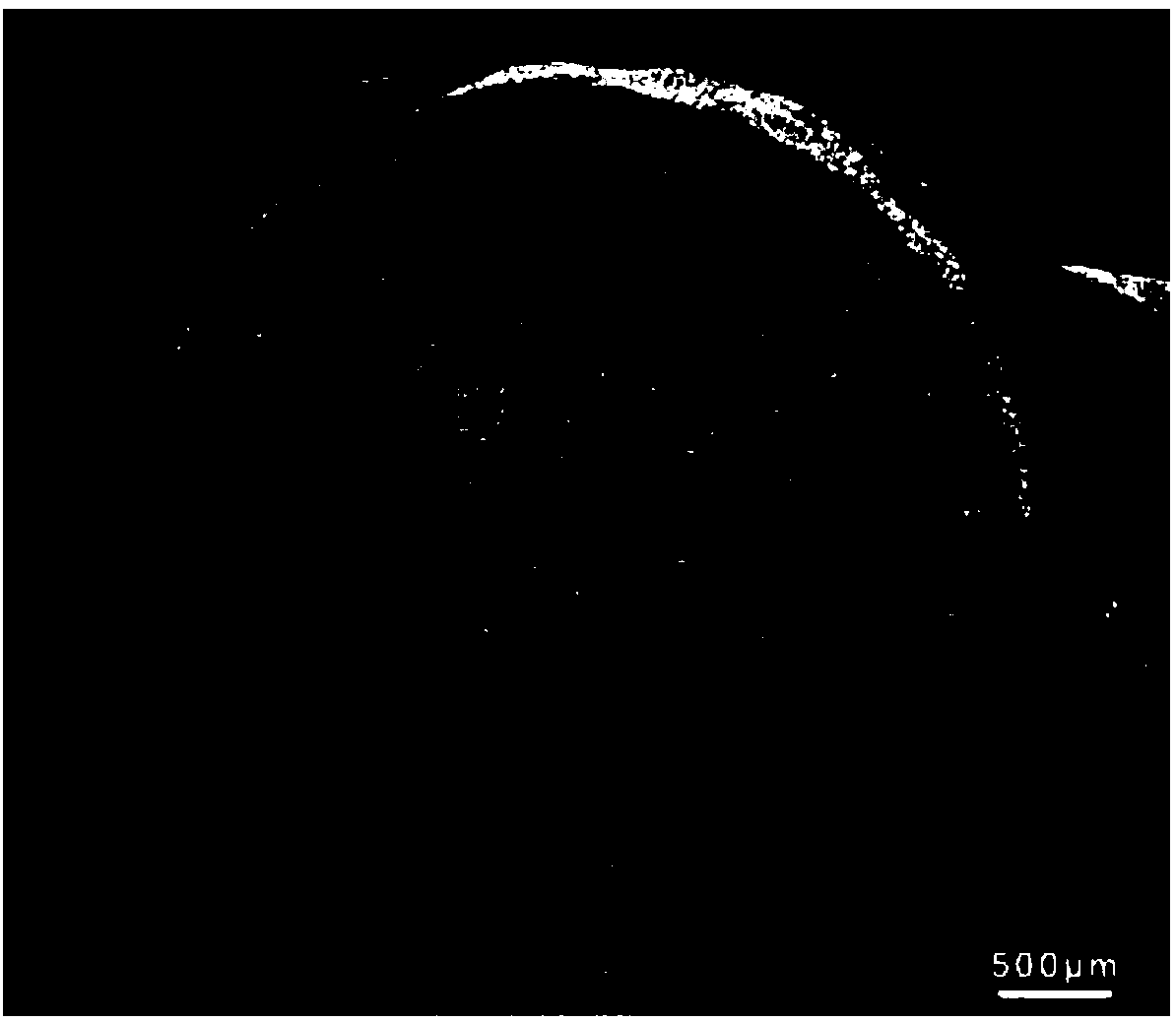

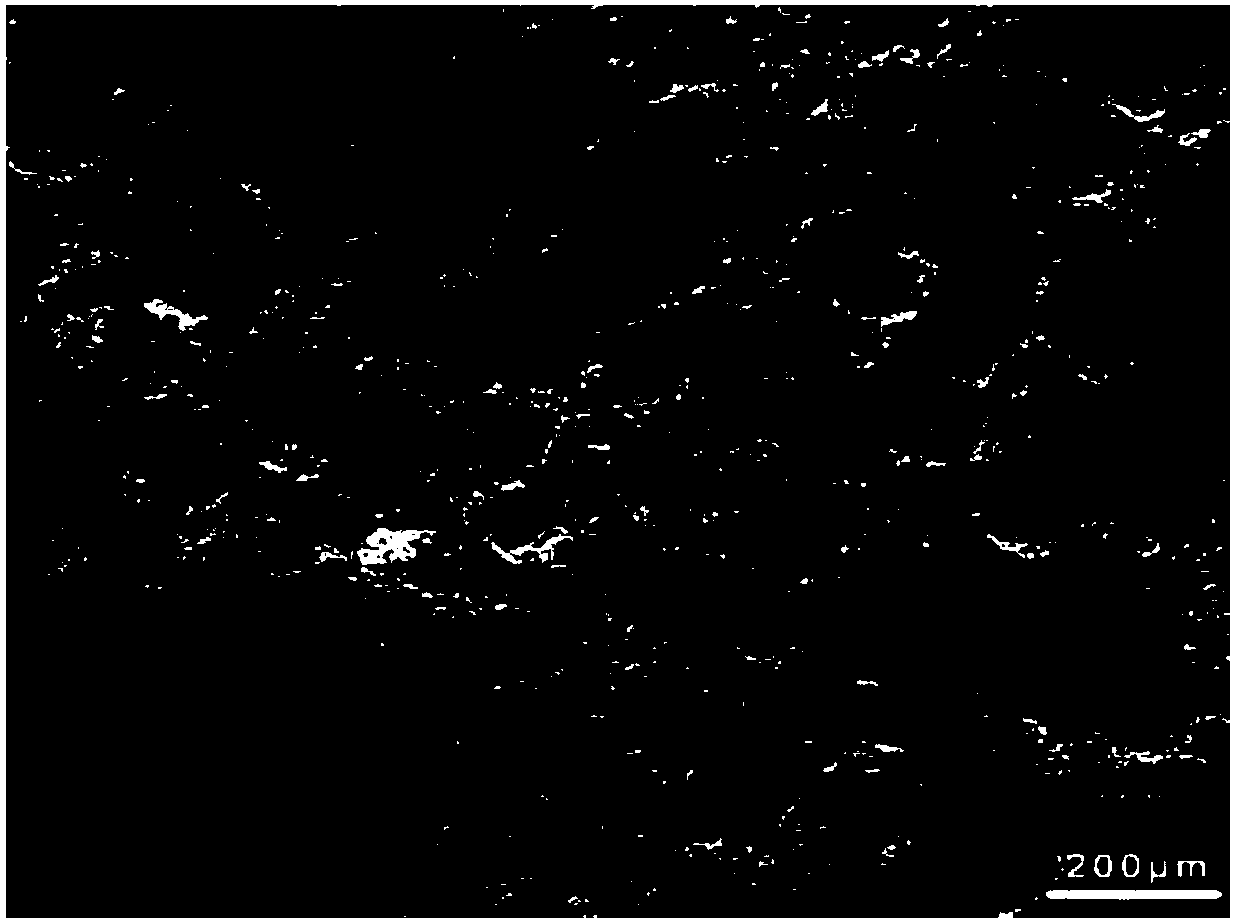

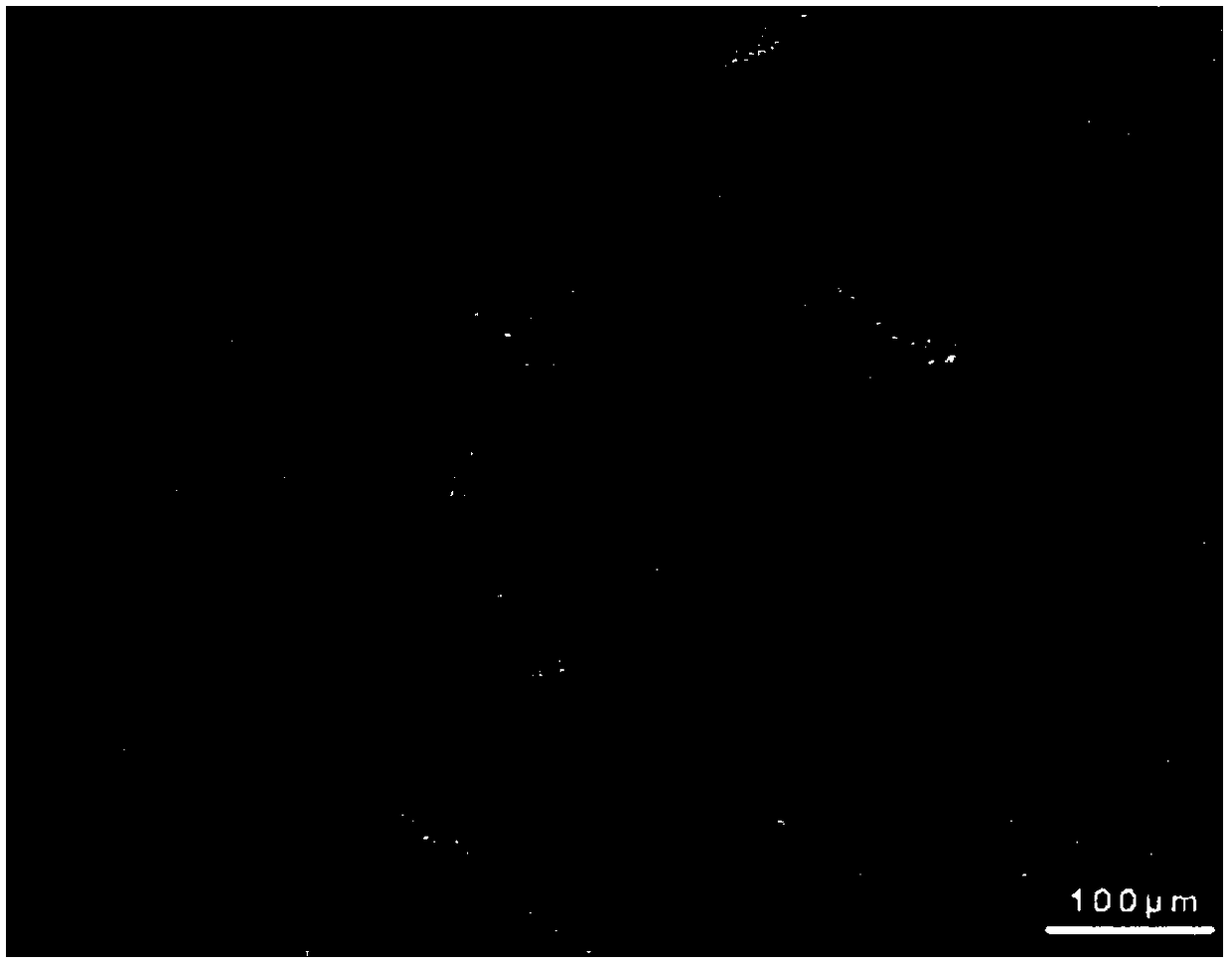

Image

Examples

Embodiment 1

[0038] (1) Preparation steps of bioactive glass powder

[0039] Add 12mol / l hydrochloric acid (3ml) into deionized water (125ml) to form a mixed solution. After stirring at room temperature for 10 minutes, add 80ml of tetraethyl orthosilicate, 8ml of triethyl phosphate, and 46g of calcium nitrate tetrahydrate in sequence, and the time interval between each addition is 30 minutes; after the addition of materials, continue to stir for 5 hours and then stop stirring , the obtained solution was aged at room temperature for 3 days to obtain a gel, and then the gel was dried at 60° C. for 1 day and at 120° C. for 1 day. Sinter in an electric furnace at 650°C for 3 hours to obtain 58S bioactive glass powder, which is ball milled and sieved, and the bioactive glass powder with a particle size of not more than 90 μm is taken for use.

[0040] (2) Preparation steps of bioactive glass bone prosthesis

[0041]Using mannitol, 58S bioactive glass powder, and PVA as raw materials, the mass...

Embodiment 2

[0045] (1) Preparation steps of bioactive glass powder

[0046] Add 12mol / l hydrochloric acid (3ml) into deionized water (125ml) to form a mixed solution. After stirring at room temperature for 10 minutes, add 80ml of tetraethyl orthosilicate, 8ml of triethyl phosphate, and 46g of calcium nitrate tetrahydrate in sequence, and the time interval between each addition is 30 minutes; after the addition of materials, continue to stir for 5 hours and then stop stirring , the obtained solution was aged at room temperature for 3 days to obtain a gel, and then the gel was dried at 60° C. for 1 day and at 120° C. for 1 day. Sinter in an electric furnace at 650°C for 3 hours to obtain 58S bioactive glass powder, which is ball milled and sieved, and the bioactive glass powder with a particle size of not more than 90 μm is taken for use.

[0047] (2) Preparation steps of bioactive glass bone prosthesis

[0048] Ammonium bicarbonate, starch, 58S bioactive glass powder, and PVA are used as...

Embodiment 3

[0052] (1) Preparation steps of bioactive glass powder

[0053] Add 12mol / l hydrochloric acid (3ml) into deionized water (125ml) to form a mixed solution. After stirring at room temperature for 10 minutes, add 80ml of tetraethyl orthosilicate, 8ml of triethyl phosphate, and 46g of calcium nitrate tetrahydrate in sequence, and the time interval between each addition is 30 minutes; after the addition of materials, continue to stir for 5 hours and then stop stirring , the obtained solution was aged at room temperature for 3 days to obtain a gel, and then the gel was dried at 60° C. for 1 day and at 120° C. for 1 day. Sinter in an electric furnace at 650°C for 3 hours to obtain 58S bioactive glass powder, which is ball milled and sieved, and the bioactive glass powder with a particle size of not more than 90 μm is taken for use.

[0054] (2) Preparation steps of bioactive glass bone prosthesis

[0055] Using ammonium bicarbonate, starch, mannitol, 58S bioactive glass powder, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com