Method for improving quality of polycrystalline silicon thin film obtained through low-pressure chemical vapor phase deposition

A low-pressure chemical vapor phase and polysilicon thin film technology, which is applied in the direction of gaseous chemical plating, coating, metal material coating process, etc., can solve the problems of polysilicon thin film fog point and the inability to prepare polysilicon thin film with high quality, and achieve yield and Effect of Reliability Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

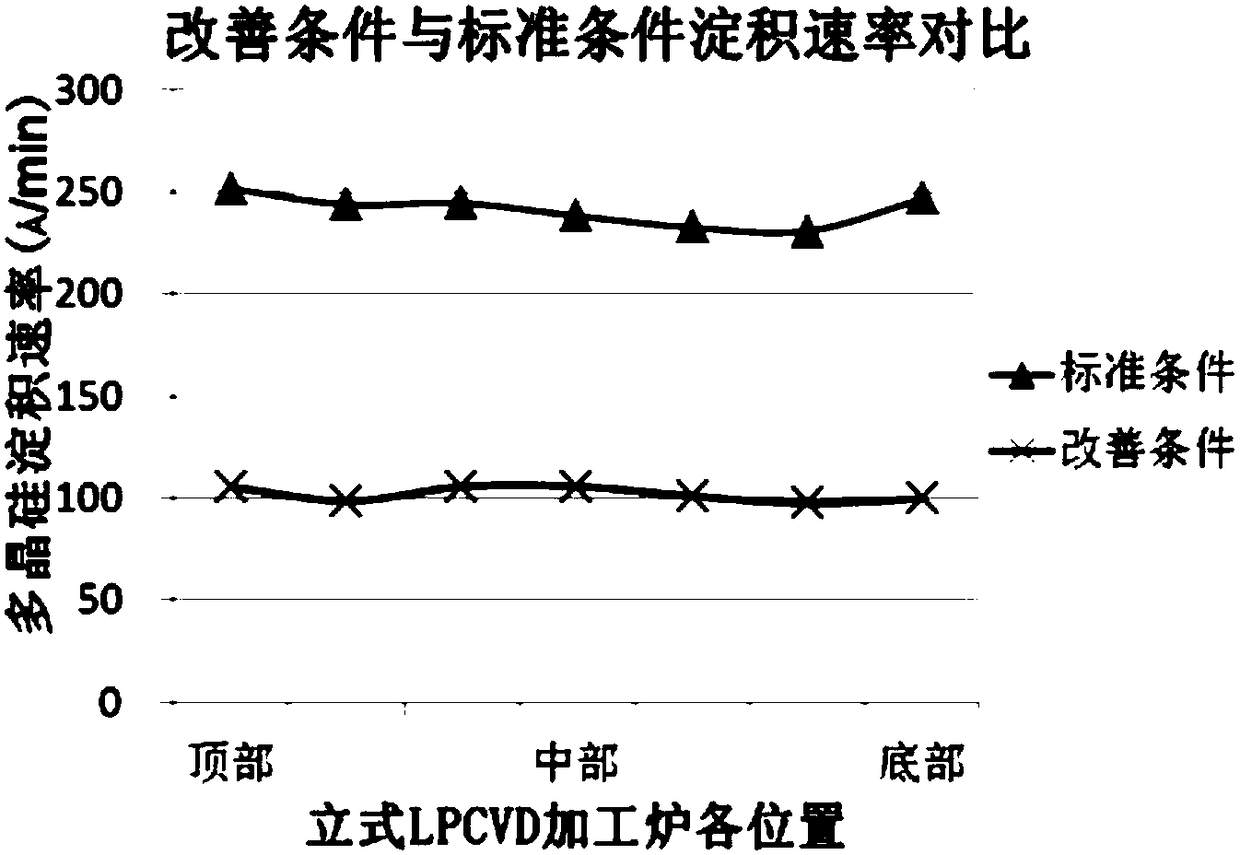

[0020] Polysilicon thin films are mainly deposited by low-pressure chemical vapor deposition (LPCVD). SiH is commonly used in the prior art 4 , Thermal decomposition deposition is carried out at a temperature of about 640-660°C.

[0021] SiH 4 =SiH 2 (gas)+H 2 (1)

[0022] SiH 2 +Si (solid)=2[Si (solid)-H * ] (2)

[0023] 2[Si(solid)-H * ]=2Si (solid)+H 2 (3)

[0024] In the formula, Si (solid) represents the silicon atoms deposited on the surface, H * Indicates hydrogen atoms adsorbed on the silicon surface. Wherein (1) (2) two steps are carried out very quickly; The 3rd step is that the process of chemical bonding is carried out very slowly. Therefore, the polysilicon deposition rate is mainly determined by the speed of surface bonding in step (3). That is, it is determined by the speed of the surface-controlled reaction process that the reactant "dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com