Preparation method of food bleaching agent

A bleaching agent and food technology, applied in the field of food processing, can solve the problems of leaving precipitation, easy to cause harm to the environment and human body, etc., to achieve the effect of not easily broken, protecting effective ingredients, and improving bleaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A kind of preparation method of food bleaching agent, this preparation method comprises the steps:

[0023] (1) Grind soybeans and pass through a 100-120 mesh sieve to obtain the sieved product. According to the mass ratio of 1:7~8:7~8, mix the sieved product, distilled water, and sodium borate buffer solution, and mix them with 100 Vibrate at a rate of ~120r / min for 25~30min, filter with filter paper to obtain the filtrate, mash the chaff of Hericium erinaceus, add distilled water 5~6 times the weight of the chaff of Hericium erinaceus, and homogenize at 8000~10000r / min for 2~ 4min, get homogenate, put the homogenate into a container, extract at 40~60℃, 200~300r / min for 1~2h, get extract, centrifuge at 3000~4000r / min for 8~10min , take the supernatant, mix the filtrate and the supernatant evenly according to the mass ratio of 10~15:2~3, and obtain the mixed solution, and put the macroporous adsorption resin and the mixed solution in the In a shaker, shake at a tempera...

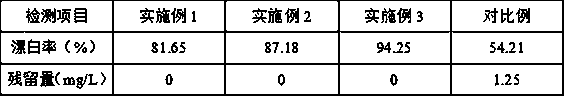

Embodiment 1

[0027] The model of macroporous adsorption resin is HZ202.

[0028] The sodium borate buffer is mixed with sodium chloride, disodium borate, sodium hydrogen borate and water according to the mass ratio of 8:6:1:30, and stirred evenly to obtain the sodium borate buffer.

[0029] The extraction solution is mixed with green tea and ethanol solution at a mass ratio of 1:80, stirred evenly, and then extracted at a temperature of 48°C for 30 minutes to obtain the extraction solution.

[0030] A kind of preparation method of food bleaching agent, this preparation method comprises the steps:

[0031](1) Grind soybeans and pass through a 100-mesh sieve to obtain the sieved product. According to the mass ratio of 1:7:7, mix the sieved product, distilled water, and sodium borate buffer solution, and shake at a speed of 100r / min for 25min , filter with filter paper to get the filtrate, mash the chaff of Hericium erinaceus, add distilled water with 5 times the quality of the chaff of Heri...

Embodiment 2

[0035] The model of macroporous adsorption resin is HZ801.

[0036] The sodium borate buffer is mixed with sodium chloride, disodium borate, sodium hydrogen borate and water according to the mass ratio of 8:6:1:35, and stirred evenly to obtain the sodium borate buffer.

[0037] The extraction solution is mixed with green tea and ethanol solution according to the mass ratio of 1:80, stirred evenly, and then extracted at a temperature of 49°C for 35 minutes to obtain the extraction solution.

[0038] A kind of preparation method of food bleaching agent, this preparation method comprises the steps:

[0039] (1) Grind soybeans and pass through a 110-mesh sieve to obtain the sieved product. According to the mass ratio of 1:7:7, mix the sieved product, distilled water, and sodium borate buffer solution, and shake at a speed of 110r / min for 27min , filter with filter paper to obtain the filtrate, mash the chaff of Hericium erinaceus, add distilled water with 5 times the quality of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com