Multihole titanium-magnesium alloy artificial bone capable of promoting bone growth and preparation method thereof

A technology for bone growth and titanium-magnesium alloy, which is applied in the directions of additive manufacturing, tissue regeneration, and additive processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The invention also discloses a porous titanium-magnesium alloy artificial bone capable of promoting bone growth and a preparation method thereof, comprising the following steps:

[0059] (1) The metal powder of the following composition (percentage by weight) is mixed into titanium alloy powder:

[0060] 0.3-9.5% molybdenum,

[0061] 1.5-6.5% nickel,

[0062] 2.5-14.5% cobalt,

[0063] 1.5-3.5% yttrium,

[0064] 1.5-5.5% niobium,

[0065] 2-3.0% magnesium,

[0066] The remainder is titanium and unavoidable impurities;

[0067] The sum of the above components is 100%;

[0068] (2) Molding method: The above-mentioned titanium-magnesium alloy powder is sintered with a German EOSINT M290 metal powder sintering system, and a selective laser sintering (SLS for short) is adopted, and the laser transmitter type is a b-fibre ytterbium fiber laser transmitter 200W or 400W, variable focal length diameter 200-480μm thickness value, optical scanning system F-theta lens, the s...

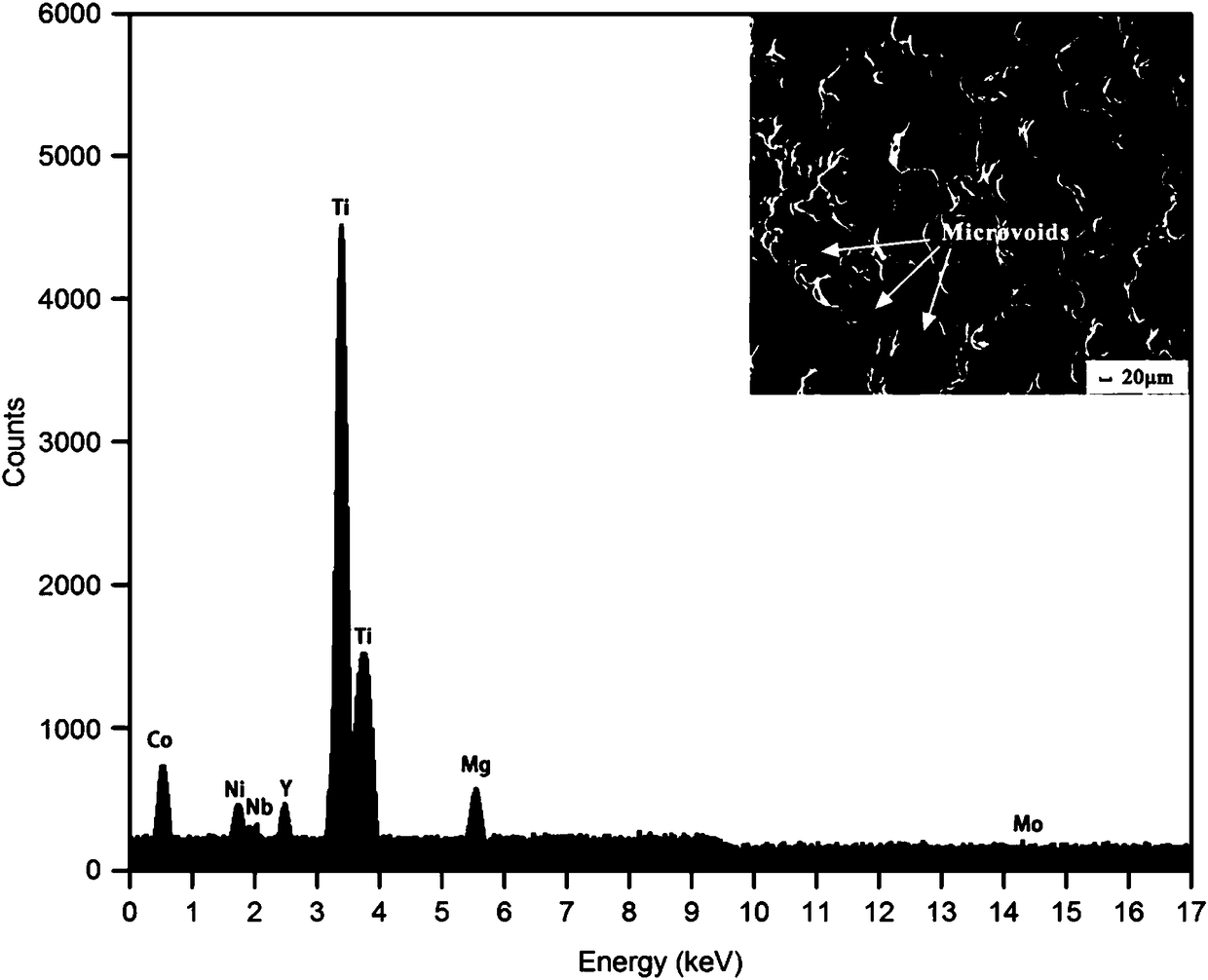

Embodiment 1

[0070] Metal powder is mixed into titanium alloy powder, wherein, described titanium alloy powder is made of the molybdenum of 0.5% (weight), and the nickel of 1.5% (weight), 2.5% cobalt, the yttrium of 1.5% (weight), 1.3% (weight) ) of niobium, .

[0071] 2% by weight of magnesium. The rest is composed of titanium and unavoidable impurities, the sum of the above components is 100%.

[0072] Molding method: The above-mentioned titanium-magnesium alloy powder is used in the German EOSINT M290 metal powder sintering system, using Selective Laser Sintering (SLS for short), and the laser transmitter type is b-fibre ytterbium fiber laser transmitter 200W, which can be The diameter of the variable focal length is 200 μm, the thickness value is 200 μm, the optical scanning system is F-theta lens, the size of the titanium-magnesium alloy artificial bone of the present invention is 260×260×315mm, and the power supply can be selected: 220V, 32A. The laser scanning speed is 6.0 m / s, an...

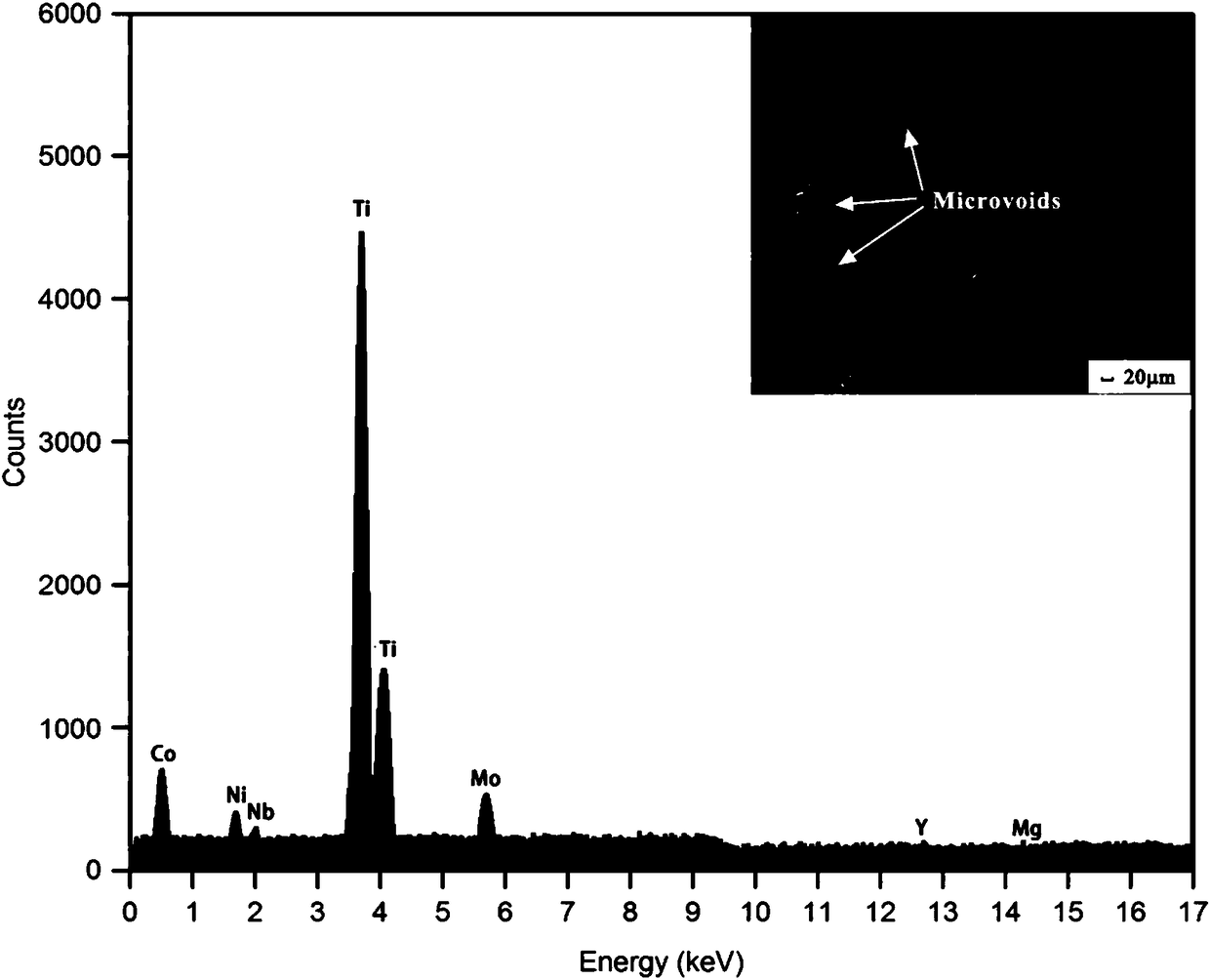

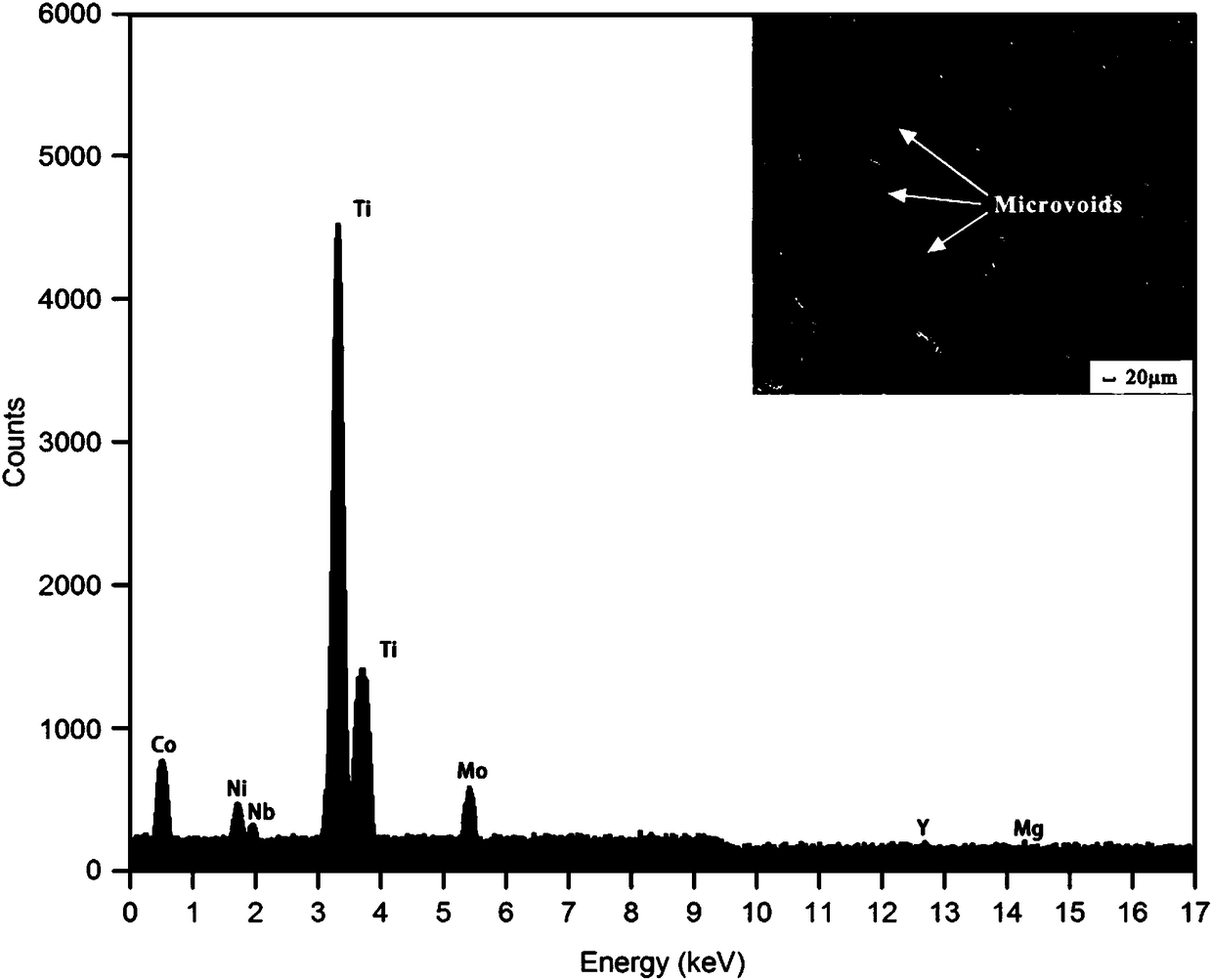

Embodiment 2

[0074] Metal powder is mixed into titanium alloy powder, wherein, described titanium alloy powder is made of the molybdenum of 4.5% (weight), and the nickel of 4% (weight), 7.5% cobalt, the yttrium of 2.5% (weight), 3.5% (weight) ) of niobium, .2.5% by weight of magnesium. The rest is composed of titanium and unavoidable impurities, the sum of the above components is 100%.

[0075] Molding method: The above-mentioned titanium-magnesium alloy powder is used in the German EOSINT M290 metal powder sintering system, using Selective Laser Sintering (SLS for short), and the laser transmitter type is b-fibre ytterbium fiber laser transmitter 200W, which can be The diameter of the variable focal length is 300 μm, the thickness value is 300 μm, the optical scanning system is F-theta lens, the size of the titanium-magnesium alloy artificial bone of the present invention is 260×260×315mm, and the power supply can be selected: 220V, 32A. The laser scanning speed is 6.5 m / s, and the metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com