Comprehensive recycling method for vanadium-contained coal-pyrite

A technology of pyrite and coal series, which is applied in the field of comprehensive recycling of vanadium-containing coal series pyrite, can solve the problems of high consumption of calcium oxide, etc., and achieve the effects of high comprehensive utilization rate, low consumption and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: The vanadium-containing coal-measure pyrite in this example adopts a certain vanadium-containing coal-measure pyrite in Guizhou, which contains V 2 o 5 0.67%, C 12.62%, S 6.34%, useful minerals are vanadium-containing coal, pyrite, gangue minerals are mainly quartz, kaolinite, etc.;

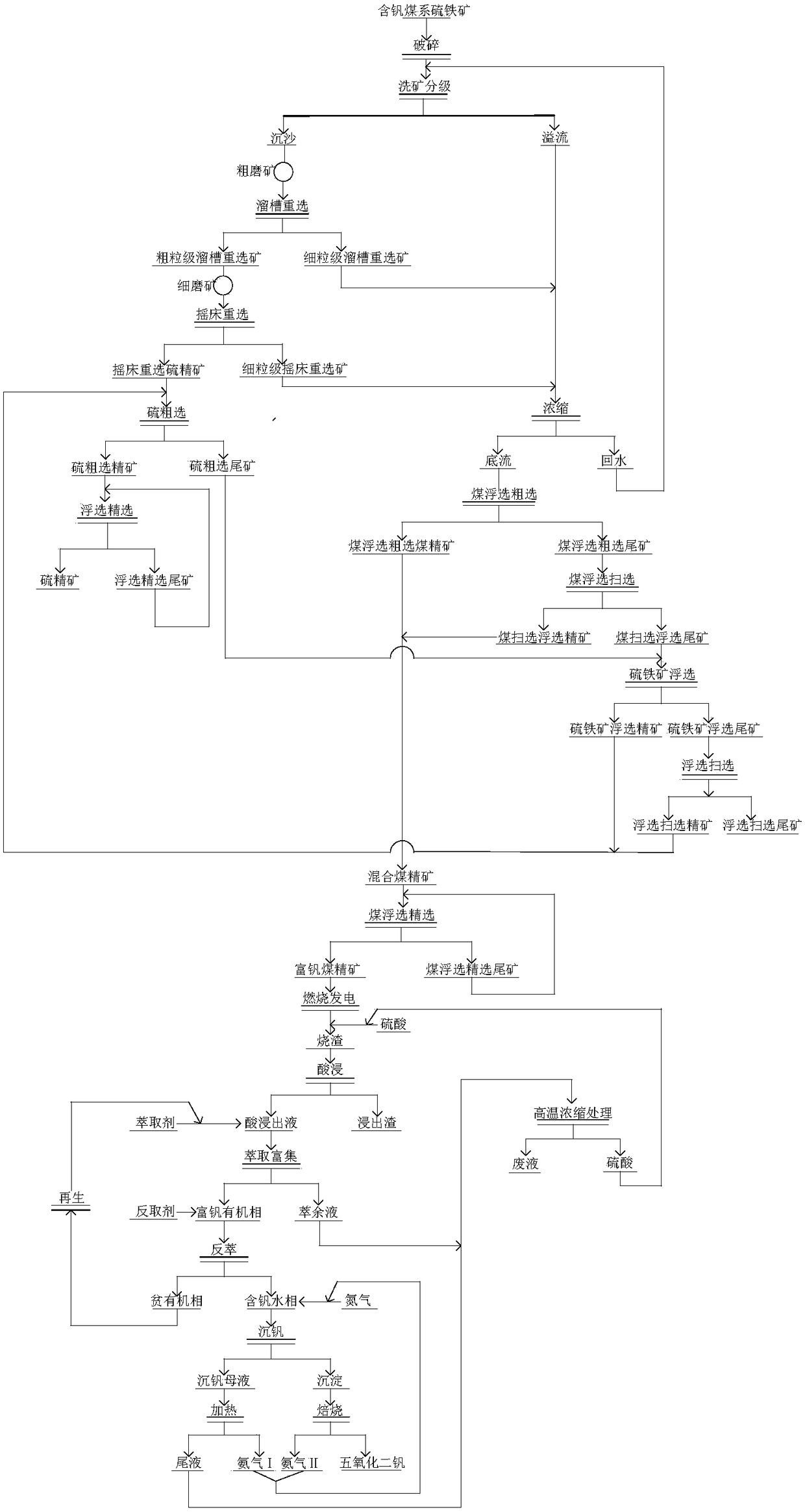

[0034] Such as figure 1 Shown, a kind of vanadium-containing coal measures pyrite comprehensive recycling method, concrete steps are as follows:

[0035] (1) Crushing the vanadium-containing coal-based pyrite to a particle size of -3mm, and then using a classifier to wash the ore to obtain coarse-grained sand and fine-grained overflow;

[0036] (2) carry out coarse grinding to particle diameter-0.074mm content of step (1) gained sedimentation and account for 50.64%, then carry out chute re-election to obtain coarse-grained chute re-concentration and fine-grained chute re-concentration;

[0037] (3) Finely grind the coarse-grained chute gravity separation ore obtained in ste...

Embodiment 2

[0048] Embodiment 2: The vanadium-containing coal-measure pyrite in this embodiment adopts a certain vanadium-containing coal-measure pyrite in Guizhou, which contains V 2 o 5 0.67%, C 12.62%, S 6.34%, useful minerals are vanadium-containing coal, pyrite, gangue minerals are mainly quartz, kaolinite, etc.;

[0049] Such as figure 1 Shown, a kind of vanadium-containing coal measures pyrite comprehensive recycling method, concrete steps are as follows:

[0050] (1) Crushing the vanadium-containing coal-based pyrite to a particle size of -3mm, and then using a classifier to wash the ore to obtain coarse-grained sand and fine-grained overflow;

[0051] (2) carry out coarse grinding to particle size-0.074mm content of step (1) gained sedimentation and account for 48.64%, then carry out chute re-election to obtain coarse-grained chute re-concentration ore and fine-grained chute re-concentration;

[0052] (3) Finely grind the coarse-grained chute gravity separation ore obtained i...

Embodiment 3

[0063] Embodiment 3: The vanadium-containing coal-measure pyrite in this embodiment adopts a certain vanadium-containing coal-measure pyrite in Guizhou, which contains V 2 o 5 0.67%, C 12.62%, S 6.34%, useful minerals are vanadium-containing coal, pyrite, gangue minerals are mainly quartz, kaolinite, etc.;

[0064] Such as figure 1 Shown, a kind of vanadium-containing coal measures pyrite comprehensive recycling method, concrete steps are as follows:

[0065] (1) Crushing the vanadium-containing coal-based pyrite to a particle size of -3mm, and then using a classifier to wash the ore to obtain coarse-grained sand and fine-grained overflow;

[0066] (2) carry out coarse grinding to particle diameter-0.074mm content of step (1) gained sedimentation and account for 53.98%, then carry out chute re-election to obtain coarse-grained chute re-concentration ore and fine-grained chute re-concentration;

[0067] (3) Finely grind the coarse-grained chute gravity separation ore obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com