One-step preparation of spherical crossed nickel hydroxide nanosheets based on porous nickel framework

A technology of porous nickel and nanosheets, which is applied in the field of preparation of β-Ni2 nanosheets, can solve the problems of large pore size, long production cycle, complicated procedures, etc., and achieve the effects of simplified production process, high sphericity, and simple and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

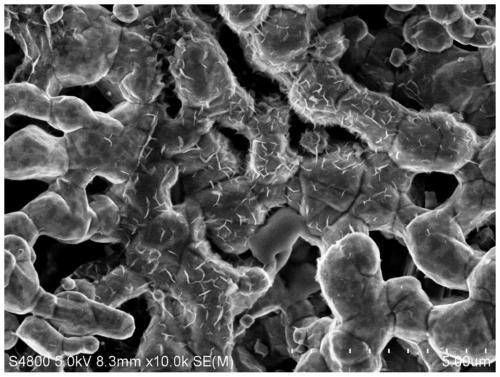

[0027] Weigh 0.1g of sodium chloride, fully grind for 10min, mix evenly with 0.3g of reduced nickel powder with a particle size of 5 microns, place it in a clean cylindrical mold with an inner diameter of 2cm, place it in the center of a hydraulic press after closing the mold, and pressurize to 20MPa, and take it out after keeping it for 5min. Load the pressed disc-shaped blank with a quartz boat and place it in a clean quartz tube. After the air is exhausted, adjust the flow rate of hydrogen to 100 sccm and argon to 200 sccm, raise the temperature to 700 °C at a rate of 10 °C / min, and keep it for 8 hours. Bring to room temperature. The calcined dense flakes were placed in deionized water, kept in an oven at 60°C for 6 hours, and taken out. After drying, see Figure 1-4 .

Embodiment 2

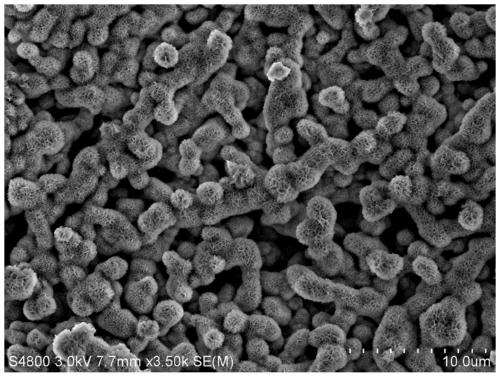

[0029] Weigh 0.2g of sodium chloride, fully grind for 10min, mix evenly with 0.2g of reduced nickel powder with a particle size of 5 microns, place it in a clean cylindrical mold with an inner diameter of 2cm, place it in the center of a hydraulic press after closing the mold, and pressurize to 20MPa, and take it out after keeping it for 5min. Load the pressed disc-shaped blank with a quartz boat and place it in a clean quartz tube. After the air is exhausted, adjust the flow rate of hydrogen to 100 sccm and argon to 200 sccm, raise the temperature to 700 °C at a rate of 10 °C / min, and keep it for 8 hours. Bring to room temperature. Place the calcined dense flakes in deionized water, keep them in an oven at 60°C for 6 hours, take them out and dry them.

Embodiment 3

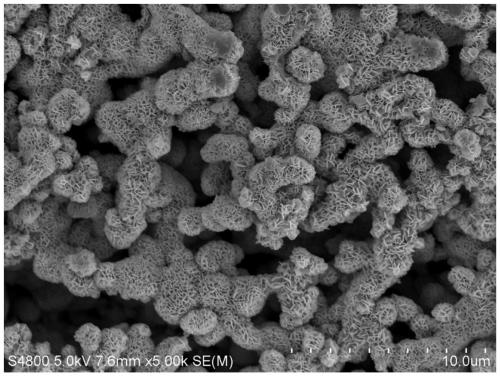

[0031] Weigh 0.2g of sodium chloride, fully grind for 10min, mix evenly with 0.2g of reduced nickel powder with a particle size of 2 microns, place it in a clean cylindrical mold with an inner diameter of 2cm, place it in the center of a hydraulic press after closing the mold, and pressurize to 20MPa, and take it out after keeping it for 5min. Load the pressed disc-shaped blank with a quartz boat and place it in a clean quartz tube. After the air is exhausted, adjust the flow rate of hydrogen to 100 sccm and argon to 200 sccm, raise the temperature to 700 °C at a rate of 10 °C / min, and keep it for 8 hours. Bring to room temperature. Place the calcined dense flakes in deionized water, keep them in an oven at 60°C for 6 hours, take them out and dry them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com