Implant abutment gum-penetrating structure having visible light functionalization function and production method thereof

An implant and visible light technology, applied in the field of medical implantation, can solve the problems of increasing patient treatment expenditure, single anti-inflammatory range, and limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

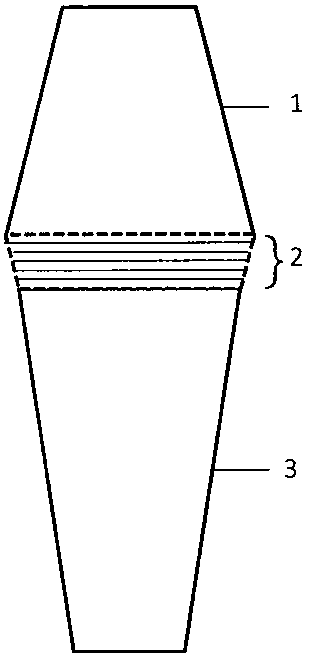

[0030] Embodiment 1: The implant abutment is made of titanium.

[0031] 1) The implant abutment is polished sequentially with 1000#-5000# water sandpaper until the surface is smooth without obvious defects;

[0032] 2) Then, the polished implant abutment was ultrasonically cleaned in acetone, ethanol and distilled water for 5-6 minutes respectively; dried at room temperature;

[0033] 3) Electrode setting: the anode is the implant abutment, and the cathode is the platinum ring;

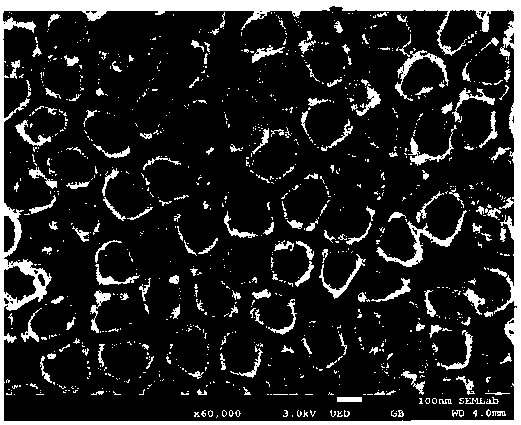

[0034] 4), anodic oxidation: 75% glycerin solution by volume, 0.27mol / L ammonium fluoride system as electrolyte, anode voltage of 10V, 30V or 60V, in the abutment of the implant abutment through the gingival structure 2 Surface preparation of self-assembled TiO 2 Nanotubes; the oxidation time is set to 3h, and after the oxidation is completed, the implant abutment is ultrasonically cleaned in an ethanol solution, and air-dried naturally in the air;

[0035] 5) Heat treatment: Calcinate the oxidized...

Embodiment 2

[0038] Embodiment 2: The implant abutment is made of titanium.

[0039] 1) The implant abutment is polished sequentially with 1000#-5000# water sandpaper until the surface is smooth without obvious defects;

[0040] 2) Then, the polished implant abutment was ultrasonically cleaned in acetone, ethanol and distilled water for 5-6 minutes respectively; dried at room temperature;

[0041] 3) Electrode setting: the anode is the implant abutment, and the cathode is the platinum ring;

[0042] 4), anodic oxidation: 75% glycerin solution by volume, 0.27mol / L ammonium fluoride system as electrolyte, anode voltage of 30V, self-assembled on the surface of the abutment transgingival structure 2 of the implant abutment TiO 2 Nanotubes; the oxidation time is set to 1h, 5h, and 10h. After the oxidation is completed, the implant abutment is ultrasonically cleaned in ethanol solution and air-dried naturally in the air;

[0043] 5) Heat treatment: Calcinate the oxidized and air-dried implant a...

Embodiment 3

[0046] Embodiment 3: The implant abutment is made of titanium.

[0047] 1) The implant abutment is polished sequentially with 1000#-5000# water sandpaper until the surface is smooth without obvious defects;

[0048] 2) Then, the polished implant abutment was ultrasonically cleaned in acetone, ethanol and distilled water for 5-6 minutes respectively; dried at room temperature;

[0049] 3) Electrode setting: the anode is the implant abutment, and the cathode is the platinum ring;

[0050] 4), anodic oxidation: 75% glycerin solution by volume, 0.27mol / L ammonium fluoride system as electrolyte, anode voltage of 30V, self-assembled on the surface of the abutment transgingival structure 2 of the implant abutment TiO 2 Nanotubes; the oxidation time is set to 1h, 5h, and 10h. After the oxidation is completed, the implant abutment is ultrasonically cleaned in ethanol solution and air-dried naturally in the air;

[0051] 5) Heat treatment: Calcinate the oxidized and air-dried implant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com