Method for degrading benzidine by using Oriental Variegated Coralbean leaf crude enzyme solution

A technology of benzidine and crude enzyme liquid, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of high production cost, cumbersome removal process, easy to cause explosion, etc. Low cost, easy availability, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

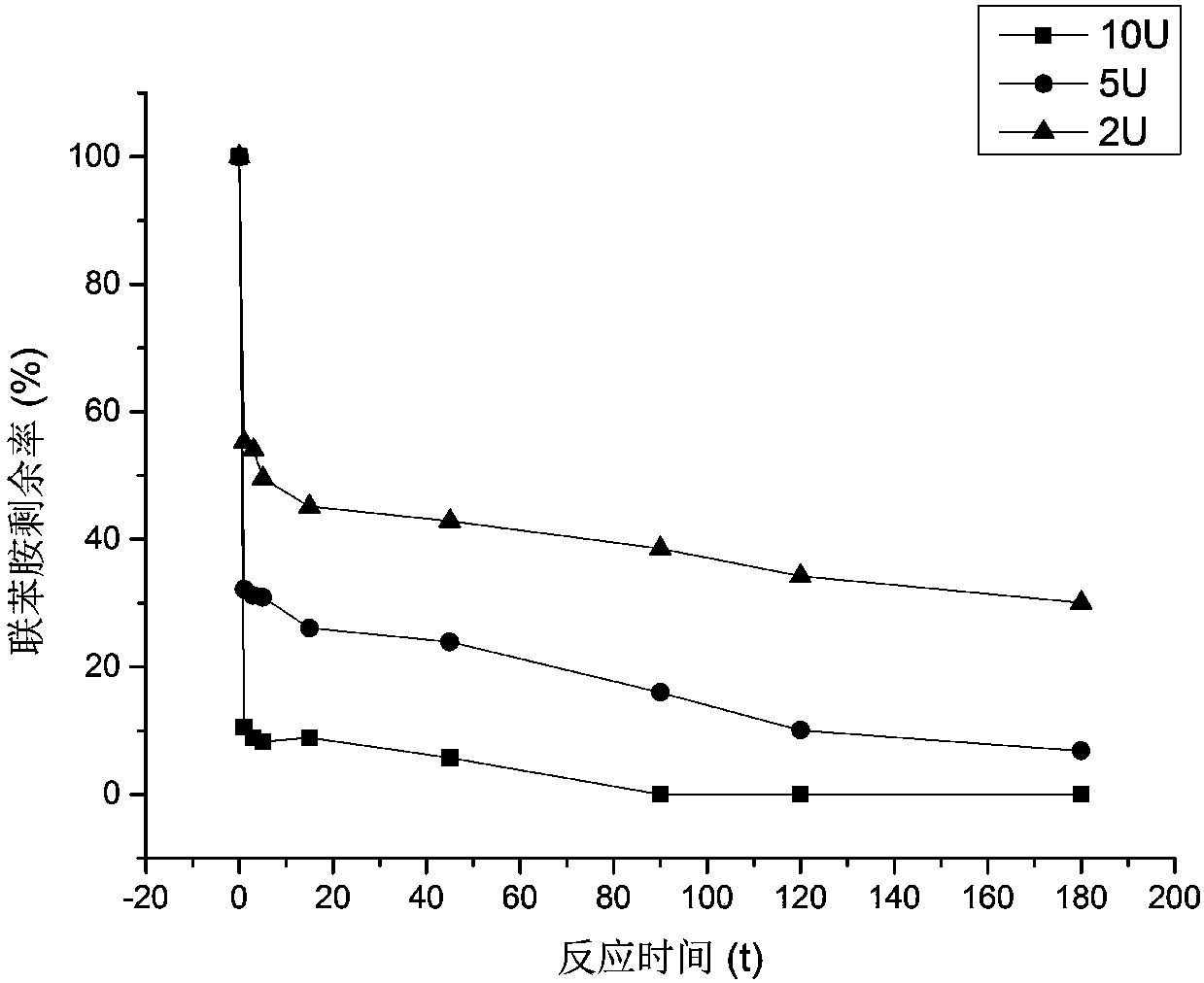

[0027] Example 1 Effects of different concentrations of Erythrina japonica crude enzymes on the removal of benzidine

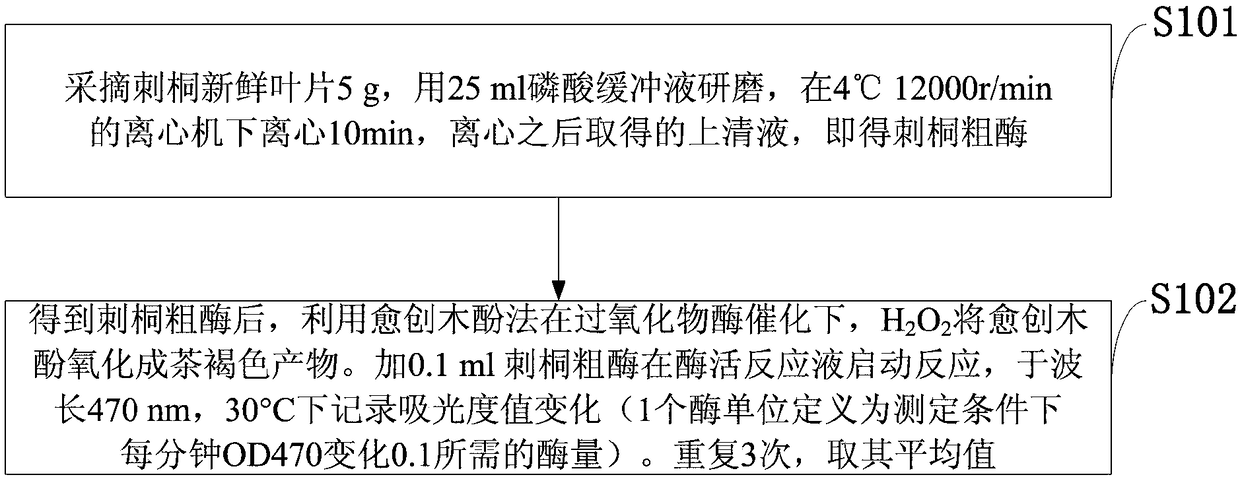

[0028] Determination of Erythrina POD (Peroxidase) Enzyme Activity by Taking Crude Enzyme from Erythrina

[0029] Take 4ml of benzidine, respectively take 10U, 5U, and 2U of enzyme activity units, and the corresponding Erythrina enzyme solution is 42μL, 26μL, 10.4μL, pH 6.0 phosphate buffer 15.942mL, 15.958mL, 15.974mL, 1mg / L H 2 o 2 16μL;

[0030] After loading 1ml of methanol into each test tube, take 1mL of each sample at the time of control (0min), 1min, 3min, 5min, 15min, 45min, 90min, 120min, and 180min, and add 8μL KAl(SO 4 ) 2, After taking it, put it in the refrigerator for 12 hours. Then centrifuge at 4°C for 10 min at 12000 r / min.

[0031] The content of benzidine was determined by liquid chromatography.

[0032] From figure 2 It can be seen that when the enzyme activity unit is 10U, the clearance rate reaches more than 90% in the first minu...

Embodiment 2

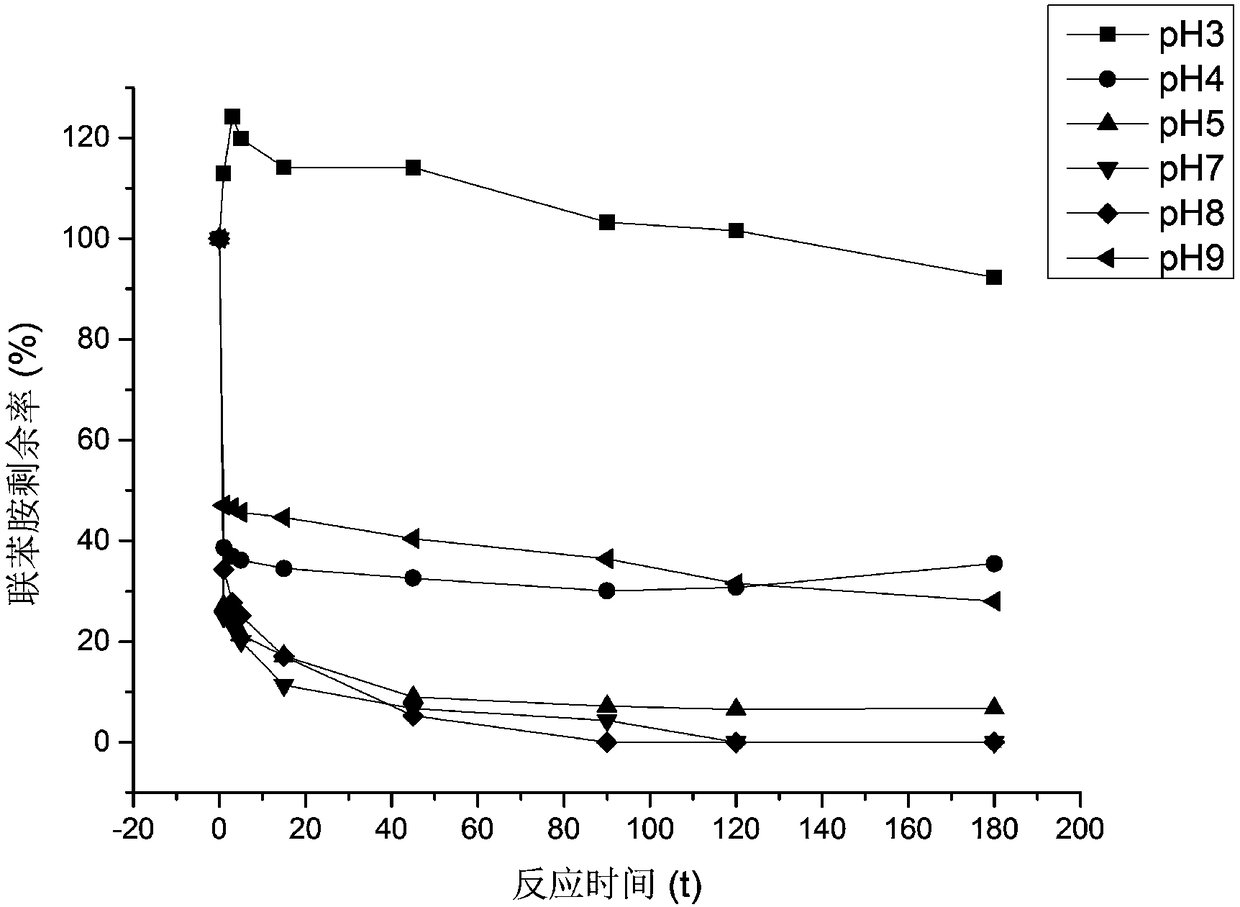

[0033] Example 2 Effects of different pH buffers on the removal of benzidine by the crude enzyme of Erythrina chinensis

[0034] Determination of enzyme activity of fresh Erythrina japonica crude enzyme

[0035] Take 4ml of benzidine, take the corresponding Erythrina enzyme solution of 5U enzyme activity units, use pH 3.0, pH 4.0, pH 5.0, pH 7.0, pH 8.0, pH 9.0 buffer and 1mg / L H 2 o 2 16 μL. Use citric acid buffer for pH 3.0, acetate buffer for pH 4.0 and 5.0, phosphate buffer for pH 6.0-8.0, and borate buffer for pH 9.0.

[0036] After loading 1ml of methanol into each test tube, take 1mL of each sample of the control (0min), 1min, 3min, 5min, 15min, 45min, 90min, 120min, and 180min, and add 8μL of KAl (SO 4 ) 2 , After taking it, put it in the refrigerator for 12 hours. Then centrifuge at 4°C for 10 min at 12000 r / min.

[0037] The content of benzidine was determined by liquid chromatography.

[0038] From image 3 It can be seen in the figure that the clearance rat...

Embodiment 3

[0039] The influence of embodiment 3 different temperatures on the removal of benzidine by Erythrina japonica crude enzyme

[0040] Determination of enzyme activity of fresh Erythrina japonica crude enzyme

[0041] Take 4ml of benzidine, take the corresponding Erythrina enzyme solution of 5U of enzyme activity unit, take the phosphate buffer solution with pH of 7.0 and 1mg / L H 2 o 2 Under the conditions, the temperature of the reaction system was changed, and the reaction system was respectively placed in a water bath with a temperature of 25°C, 30°C, 40°C, 45°C, and 50°C.

[0042] After loading 1ml of methanol into each test tube, take 1mL of the reaction mixture of a control (0min), 1min, 3min, 5min, 15min, 45min, 90min, 120min, and 180min, and add 8μL of KAl(SO 4 ) 2 , After taking it, put it in the refrigerator for 12 hours. Then centrifuge at 4°C for 10 min at 12000 r / min.

[0043] The content of benzidine was determined by liquid chromatography.

[0044] From Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com