A warm eye-protecting matte glaze for architectural ceramic tiles and its preparation process

A preparation process, a technology of ceramic tiles, applied in the field of architectural ceramics production, can solve the problems of cold home environment, uneven glazed surface, not warm enough, etc., achieve the effect of wide source of raw materials, low cost, and expanded production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

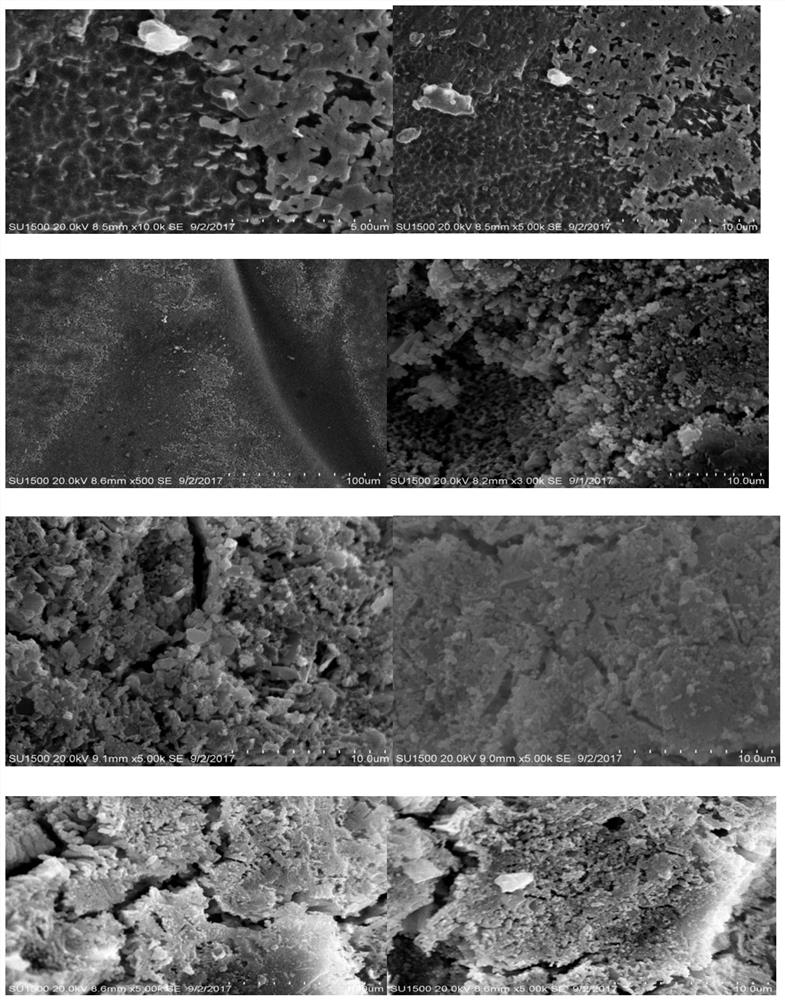

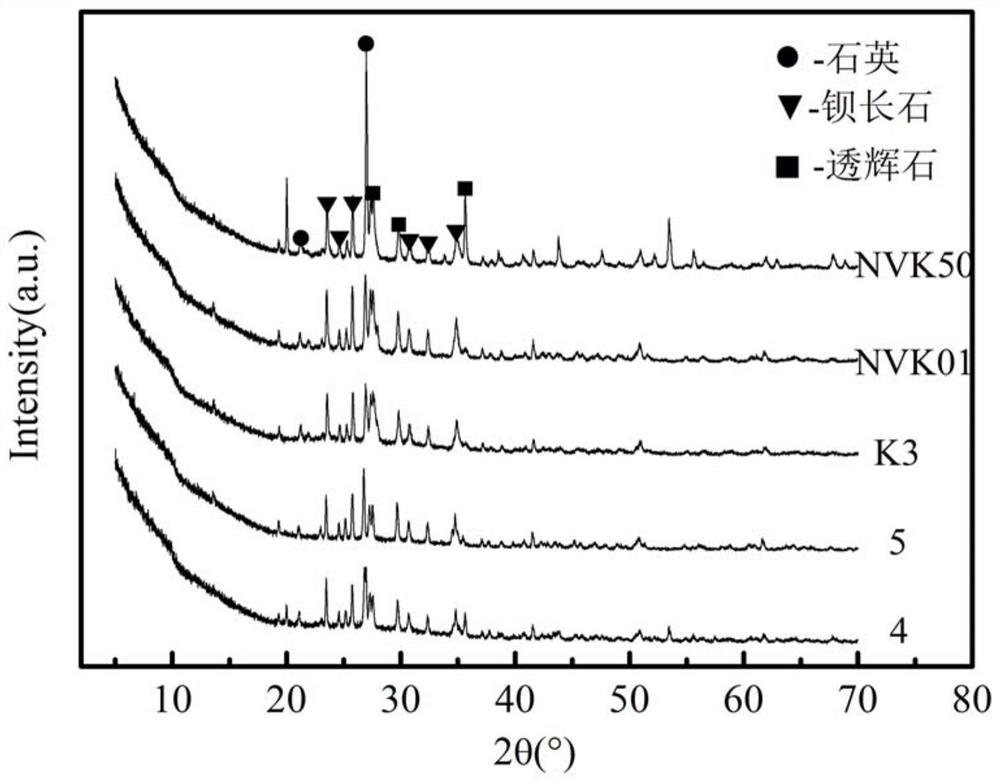

Image

Examples

Embodiment 1

[0022] The present invention is an architectural ceramic tiles with matt enamel moist goggles, a weight ratio, the ratio of the glaze raw material composition: glaze components include: of SiO 2 47.01%, Al 2 O 3 20.12%, Fe 2 O 3 0.13 %%, CaO10.41%, MgO 0.22%, K 2 O4.85%, Na 2 O3.35%, ZrO 2 9.50%, ZnO9.74%, B 2 O 3 1.69%, BaO9.93%, SrO1%.

[0023] Matte glazed tiles prepared following steps:

[0024] (1) According to the chemical composition range of the present general inorganic raw materials weighed building ceramics factory used: clay, feldspar, quartz, talc, dolomite, limestone, borax, zirconium silicate, zinc oxide, aluminum oxide, barium carbonate, and strontium, respectively pulverized to 180-350 mesh granules which, after mixing into the vitreous magma firing at 1500 deg.] C, quenched with water ceramic tiles with matt enamel frit.

[0025] (2) the frit was added a small amount of clay-based material and the glaze by mixing: ball: water = 1.5: 3: 0.8 mass ratio (refer to cl...

Embodiment 2

[0028] Example glaze raw materials composition ratio of the present embodiment: the glaze component comprises: of SiO 2 53.88%, Al 2 O 3 15.14%, Fe 2 O 3 0.38%, CaO6.09%, MgO2.44%, K 2 O 2.29%, Na 2 O 0.85%, ZrO 2 0%, ZnO3.66 %%, B 2 O 3 0%, BaO5.84%, SrO4.55%.

[0029] Matte glazed tiles prepared following steps:

[0030] (1) According to the chemical composition range of the present general inorganic raw materials weighed building ceramics factory used: clay, feldspar, quartz, talc, dolomite, limestone, borax, zirconium silicate, zinc oxide, aluminum oxide, barium carbonate, and strontium, respectively pulverized to 180-350 mesh granules which, after mixing fired into a vitreous magma at the 1540 deg.] C, quenched with water ceramic tiles with matt enamel frit.

[0031] (2) the frit was added a small amount of clay-based material and the glaze by mixing: ball: water = 1.2: 3.1: 0.9 mass ratio (refer to clay mixed glaze frit) contacting the feedstock in a ball mill, was added gla...

Embodiment 3

[0034] Example glaze raw materials composition ratio of the present embodiment: the glaze component comprises: of SiO 2 50.68%, Al 2 O 3 18.33%, Fe 2 O 3 0.19%, CaO8.46%, MgO1.43%, K 2 O 3.86%, Na 2 O 2.35%, ZrO 2 5.56%, ZnO6.74%, B 2 O 3 0.92%, BaO7.95%, SrO2.55%.

[0035] Matte glazed tiles prepared following steps:

[0036] (1) According to the chemical composition range of the present general inorganic raw materials weighed building ceramics factory used: clay, feldspar, quartz, talc, dolomite, limestone, borax, zirconium silicate, zinc oxide, aluminum oxide, barium carbonate, and strontium, respectively pulverized to 180-350 mesh granules which, after mixing into the vitreous magma firing at 1490 deg.] C, quenched with water ceramic tiles with matt enamel frit.

[0037] (2) the frit was added a small amount of clay-based material and the glaze by mixing: ball: water = 1.3: 3.1: 0.7 mass ratio (refer to clay mixed glaze frit) contacting the feedstock in a ball mill, was added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com