Reverse demulsifier for heavy oil produced fluid and preparation method of reverse demulsifier

A reverse-phase demulsifier and production fluid technology, which is applied in chemical dehydration/demulsification, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem that reverse-phase demulsifiers are not suitable for heavy oil or oil sand production fluid treatment, etc. problems, to achieve good demulsification, low equipment requirements, and rapid separation promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

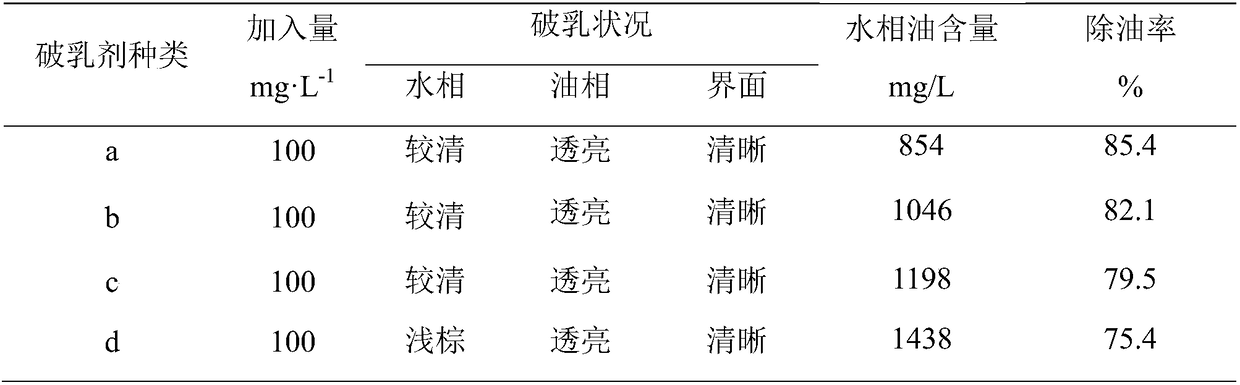

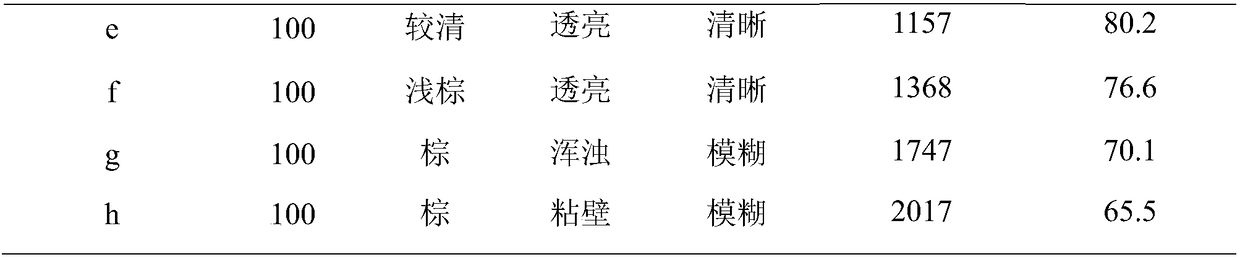

Examples

Embodiment 1

[0019] Embodiment 1: the synthesis of inverse demulsifier a

[0020] (1) Synthesis of cationic modified polyvinyl alcohol

[0021] At room temperature, slowly add 2,3-epoxypropyltrimethylammonium chloride dropwise to the aqueous solution of polyvinyl alcohol with a molecular weight of 1000. After the addition, add NaOH aqueous solution as a catalyst, and stir the reaction at 50°C for 3h . After the reaction, adjust the pH value of the system to 7-8 with dilute hydrochloric acid to obtain cation-modified polyvinyl alcohol a-1; polyvinyl alcohol, 2,3-epoxypropyltrimethylammonium chloride and The amounts of NaOH added were 20 g, 4 g and 0.23 g, respectively.

[0022] (2) Synthesis of epichlorohydrin-diethylamine polymer

[0023] At room temperature, first add epichlorohydrin, slowly add diethylamine under stirring, dropwise, then add crosslinking agent diethylenetriamine, stir and react at 70°C for 5h, and purify the obtained product with absolute ethanol-acetone , the precip...

Embodiment 2

[0028] Embodiment 2: the synthesis of inverse demulsifier b

[0029] (1) Synthesis of cationic modified polyvinyl alcohol

[0030] At room temperature, slowly add 2,3-epoxypropyltrimethylammonium chloride dropwise to the aqueous solution of polyvinyl alcohol with a molecular weight of 1500. After the addition, add NaOH aqueous solution as a catalyst, and stir the reaction at 55°C for 4h . After the reaction, adjust the pH value of the system to 7-8 with dilute hydrochloric acid to obtain cation-modified polyvinyl alcohol b-1; polyvinyl alcohol, 2,3-epoxypropyltrimethylammonium chloride and The added amounts of NaOH were 20 g, 3 g and 0.69 g, respectively.

[0031] (2) Synthesis of epichlorohydrin-diethylamine polymer

[0032] At room temperature, first add epichlorohydrin, slowly add diethylamine under stirring, after the dropwise addition, add the crosslinking agent triethylenetetramine, stir and react at 75°C for 6h, and purify the obtained product with absolute ethanol-a...

Embodiment 3

[0037] Embodiment 3: the synthesis of inverse demulsifier c

[0038] (1) Synthesis of cationic modified polyvinyl alcohol

[0039] At room temperature, slowly add 2,3-epoxypropyltrimethylammonium chloride dropwise to the aqueous solution of polyvinyl alcohol with a molecular weight of 2000. After the addition, add NaOH aqueous solution as a catalyst, and stir the reaction at 60°C for 5h . After the reaction, adjust the pH value of the system to 7-8 with dilute hydrochloric acid to obtain cation-modified polyvinyl alcohol c-1; polyvinyl alcohol, 2,3-epoxypropyltrimethylammonium chloride and The amounts of NaOH added were 20 g, 4.5 g and 1.23 g, respectively.

[0040] (2) Synthesis of epichlorohydrin-diethylamine polymer

[0041] At room temperature, first add epichlorohydrin, then slowly add diethylamine under stirring, after the dropwise addition, add the crosslinking agent tetraethylenepentamine, stir and react at 80°C for 7 hours, and purify the obtained product with abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com