Supported non-stoichiometric molybdenum-tungsten bimetallic oxide catalyst and its application

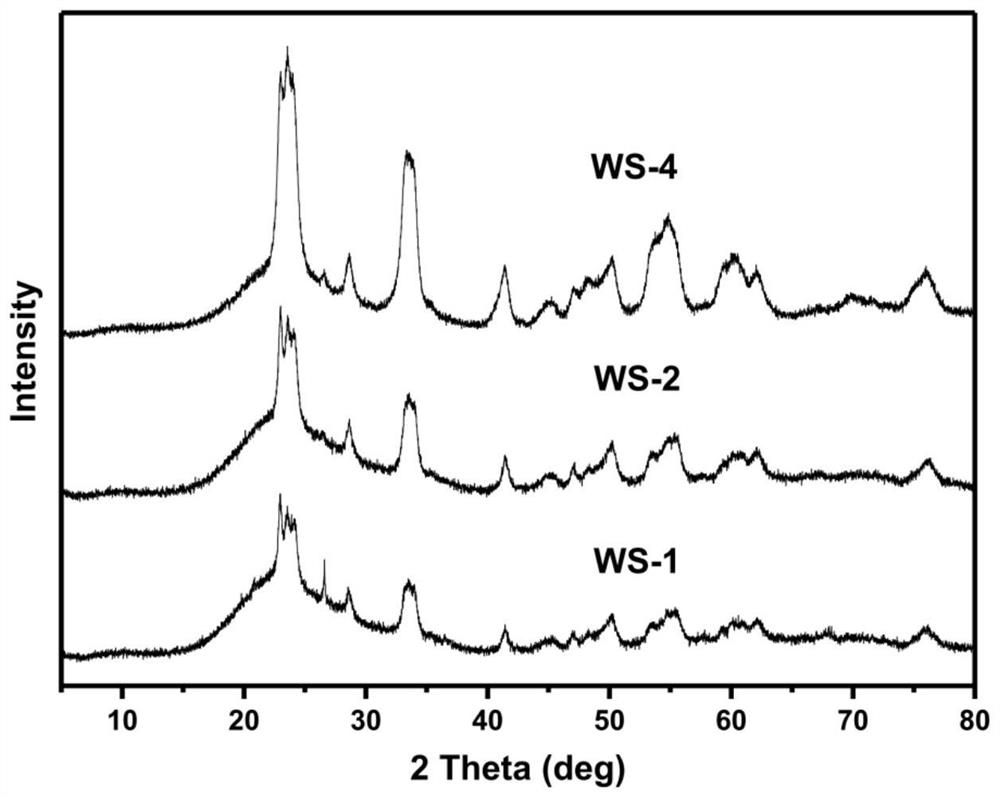

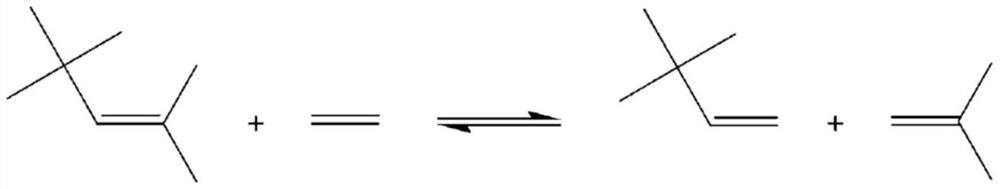

A non-stoichiometric ratio, double metal oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the limitation of catalyst application range, Weakened disproportionation performance, high price of tungsten source, etc., to achieve excellent olefin disproportionation performance, improved disproportionation activity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation of 6%Mo 0.1 W 0.9 o 2.9 / SBA-15 catalyst

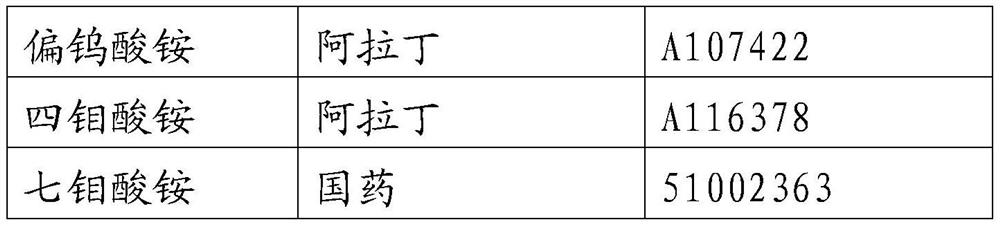

[0049] Add 1.44g of ammonium heptamolybdate and 18.04g of ammonium metatungstate into a 5L reactor, and add 1.5L of deionized water, and adjust the stirring speed to 300r / min at room temperature. After the metal salt was completely dissolved, the pH of the solution was adjusted to 8.0 with ammonia water.

[0050] 300g SBA-15 (specific surface area 623m 2 / g, average pore diameter 8nm, Tianjin Nanhua Catalyst Co., Ltd.) was slowly added to the above-mentioned salt solution, and continued to stir for 1h. Then, the temperature of the reactor was raised to 200° C. and kept at a constant temperature for 24 hours.

[0051] Feed 10v% CO / Ar mixed gas into the reactor, the concentration of CO in the mixed gas is 10v%, and the gas volume space velocity is 8h -1 , the duration is 20min. After the CO / Ar gas mixture was stopped, the reaction system was aged at 200°C for 48 hours.

[0052] Subsequently, the temperature of...

Embodiment 2

[0055] Preparation of 8% Mo 0.1 W 0.9 o 2.9 -1%MgO / coarse-porous silica gel catalyst

[0056] Add 2.82g of ammonium dimolybdate, 23.16g of ammonium metatungstate, and 15.96g of magnesium acetate into a 5L reaction kettle, and add 1.5L of deionized water, and adjust the stirring speed to 300r / min at room temperature. After the metal salt was completely dissolved, the pH of the solution was adjusted to 8.5 with ammonia water.

[0057] 300g coarse porous silica gel (specific surface area 380m 2 / g, pore diameter 8.6nm, Qingdao Ocean Chemical Co., Ltd.) the carrier was slowly added to the above saline solution, and continued to stir for 1h. Then, the temperature of the reactor was raised to 210° C. and kept at a constant temperature for 24 hours.

[0058] H was introduced into the reactor 2 / Ar mixed gas, H in the mixed gas 2 The concentration is 1v%, the gas volume space velocity is 3h -1 , the duration is 30min. stop access to H 2 After / Ar mixed gas, the reaction syst...

Embodiment 3

[0062] Preparation of 12% Mo 0.2 W 0.8 o 2.9 -1%Na 2 O / coarse-porous silica gel catalyst

[0063] Add 5.99g of ammonium heptamolybdate, 33.36g of ammonium metatungstate, and 6.49g of sodium oxalate into a 5L reaction kettle, and add 1.5L of deionized water, and adjust the stirring speed to 300r / min at room temperature. After the metal salt was completely dissolved, the pH of the solution was adjusted to 9.0 with ammonia water.

[0064] 300g coarse porous silica gel (specific surface area 380m 2 / g, pore diameter 8.6nm, Qingdao Ocean Chemical Co., Ltd.) the carrier was slowly added to the above saline solution, and continued to stir for 1h. Then, the temperature of the reactor was raised to 230° C. and kept at a constant temperature for 24 hours.

[0065] Feed 10v% CO / Ar mixed gas into the reactor, the concentration of CO in the mixed gas is 10v%, and the gas volume space velocity is 10h -1 , the duration is 30min. After the CO / Ar gas mixture was stopped, the reaction s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com