High-bonding-strength barrier packaging plastic film for food and preparing method thereof

A packaging plastic and strength technology, applied in the field of food packaging materials, can solve the problems of affecting the barrier performance and service life of packaging films, weak bonding between layers, and low strength of packaging films, so as to achieve good product safety performance and low cost. Low, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

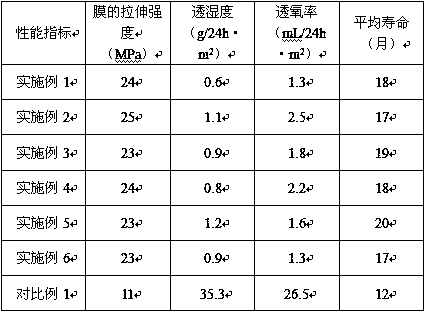

Examples

Embodiment 1

[0028] Mix 3kg of phosphorus oxychloride with 97kg of cornstarch, adjust the pH value to 10, raise the temperature to 36°C for 140min for cross-linking modification, and obtain cross-linking modified starch; then add 15kg of cations to 33kg of modified starch Carboxymethylcellulose sodium and 8kg sodium alginate were mixed evenly, then 42kg distilled water and 2kg alkylphenol polyoxyethylene ether were added and stirred for 72min to obtain a completely dissolved uniform pre-film solution; then 44kg pre-formed The film liquid is cast to form a film at a film-forming line speed of 1.8m / s, and the average thickness of the film is 0.03mm, and then 16kg of apple pectin is added to 40kg of epoxy acrylate monoester-modified carboxyl-terminated polyamide to make a slurry material, and coated on the surface of the casting film, and then rapidly hot-pressed and dried and compounded under the conditions of a pressure of 7 MPa and a temperature of 255 ° C, to obtain a barrier packaging pla...

Embodiment 2

[0036]Mix 4kg of sodium trimetaphosphate with 96kg of wheat starch, adjust the pH to 9, raise the temperature to 32°C for 145min for cross-linking modification, and obtain cross-linking modified starch; then add 12kg of cations to 32kg of modified starch Carboxymethylcellulose sodium and 6kg sodium alginate were mixed uniformly, then 49kg distilled water and 1kg alkylphenol ether sulfosuccinate sodium salt were added and stirred for 65min to obtain a completely dissolved uniform pre-film solution; then 51kg of preformed film liquid is cast to form a film at a film forming line speed of 1.6m / s, and the average thickness of the film is 0.028mm, and then 13kg of apple pectin is added to 36kg of epoxy acrylate monoester modified carboxyl-terminated polyamide Slurry was prepared in the medium, and coated on the surface of the casting film, and then quickly hot-pressed and dried and compounded under the conditions of pressure of 6 MPa and temperature of 245 ° C, to obtain a barrier p...

Embodiment 3

[0039] Mix 4kg citric acid with 96k sweet potato starch, adjust the pH value to 11, raise the temperature to 38°C for 125min for cross-linking modification, and obtain cross-linked modified starch; then add 16kg cationic carboxylate to 34kg modified starch Sodium methylcellulose and 8kg sodium alginate were mixed evenly, then 39kg of distilled water and 3kg of octylphenyl polyoxyethylene ether were added and stirred for 75min to obtain a completely dissolved uniform pre-film solution; then 37kg of pre-film The liquid is cast to form a film at a film-forming line speed of 1.9m / s, and the average thickness of the film is 0.035mm, and then 17kg of apple pectin is added to 46kg of carboxyl-terminated polyamide modified by epoxy acrylate monoester to make a slurry , and coated on the surface of the cast film, and then quickly hot-pressed and dried and compounded under the conditions of a pressure of 7 MPa and a temperature of 255 ° C, to obtain a barrier packaging plastic film for f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com