Method for evaluating cathodic protection potential range in anaerobic environment containing sulfate reducing bacteria (SRB)

A cathodic protection and evaluation method technology, applied in the field of cathodic protection potential range evaluation in anaerobic environment, achieves the effects of reliable results, avoiding insufficient protection or overprotection, and simple experimental method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

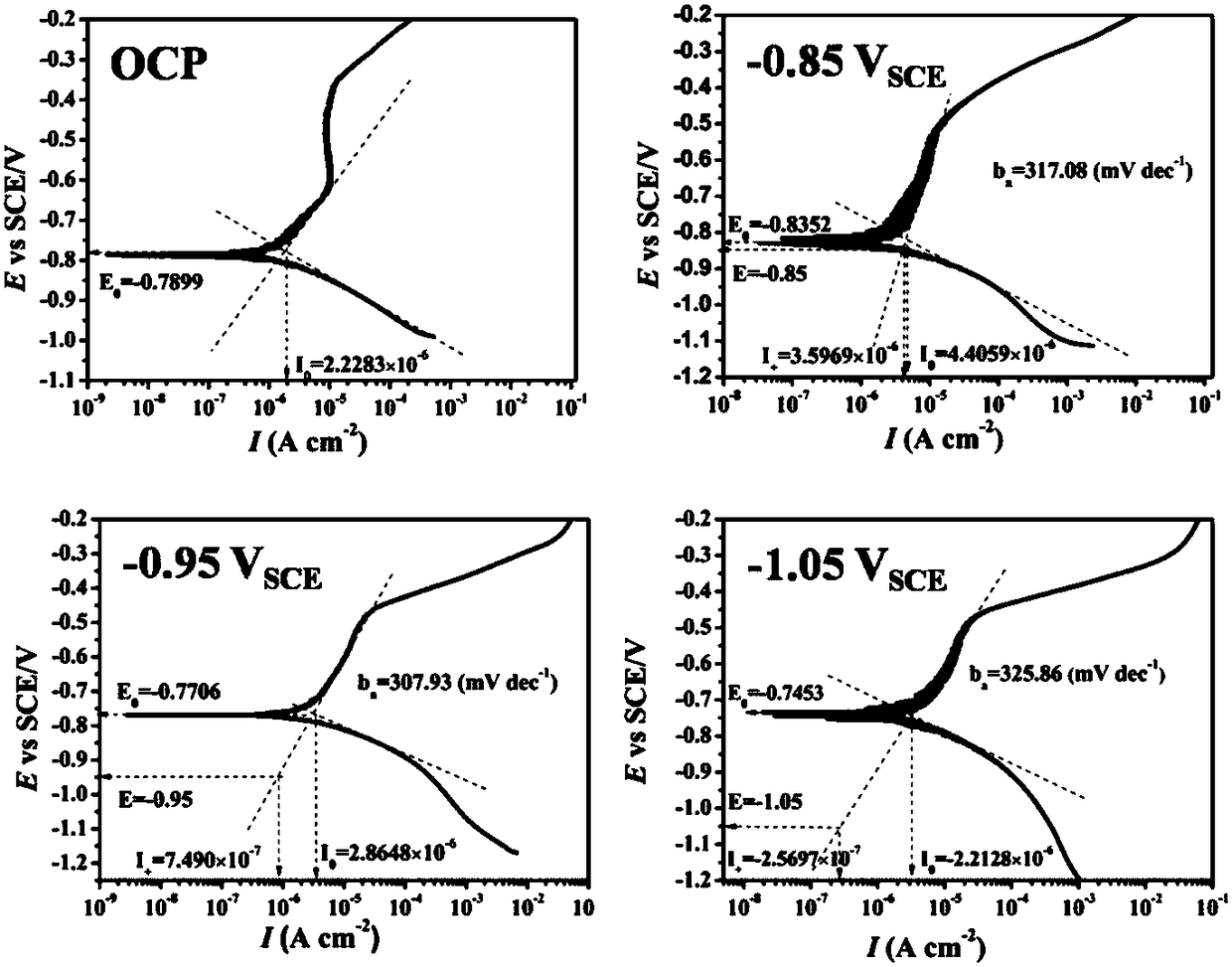

[0031] Evaluation method for cathodic protection potential range of high strength steel in anaerobic environment of sulfate reducing bacteria

[0032] 1) Prepare SRB medium. The composition of the medium is: every liter of old sea water contains: 0.5g K 2 HPO 4 , 1.0g NH 4 Cl, 0.06g CaCl 2 ·6H 2 O, 0.06g MgSO 4 ·7H 2 O, 6mL 70% sodium lactate, 1.0g yeast extract and 0.3g sodium citrate. Autoclave for 30 minutes and cool before use.

[0033] 2) Prepare the working electrode. Inlay the metal to be tested with epoxy resin. The working area is 10mm×10mm. Use 200, 600, 800, 1000, 2000, 3000 mesh water phase sandpaper to polish step by step until bright, degrease with absolute ethanol and acetone, distilled water Rinse, dry, and sterilize in an ultra-clean bench for more than 30 minutes.

[0034] 3) Assemble the three-electrode system. The high-strength steel electrode to be tested is used as the working electrode, the saturated calomel electrode is used as the reference ...

Embodiment 2

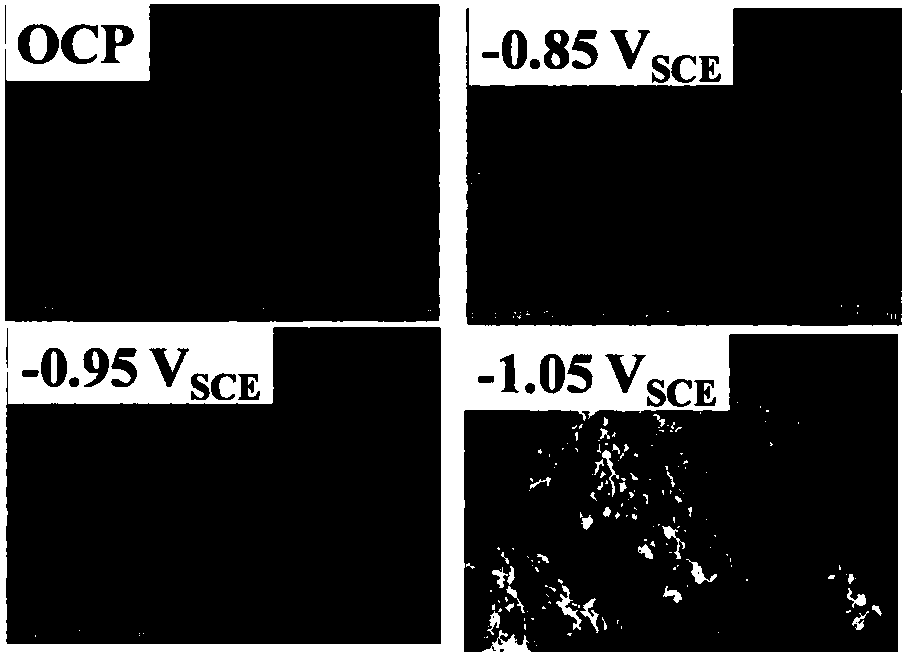

[0038] Observation of corrosion morphology of high-strength steel under different cathodic protection potentials in an anaerobic environment containing sulfate-reducing bacteria.

[0039]The test piece not subjected to potentiodynamic polarization in Example 1 was taken out for scanning electron microscope test. When performing SEM observation, wash off the suspension adsorbed on the surface of the electrode with a sterile solution. Then fix with 5% glutaraldehyde (diluted in sterile PBS). Afterwards, it was dehydrated with 50%, 70% and 100% ethanol gradients for 30 minutes each, vacuum critically dried, sprayed with gold, and placed on a scanning electron microscope for observation. The result is as figure 2 shown.

[0040] figure 2 Electron microscope observation shows that compared with the control system (OCP) without cathodic protection potential, there are obvious large cracks on the surface of high-strength steel with -0.85VSCE cathodic protection; there are still...

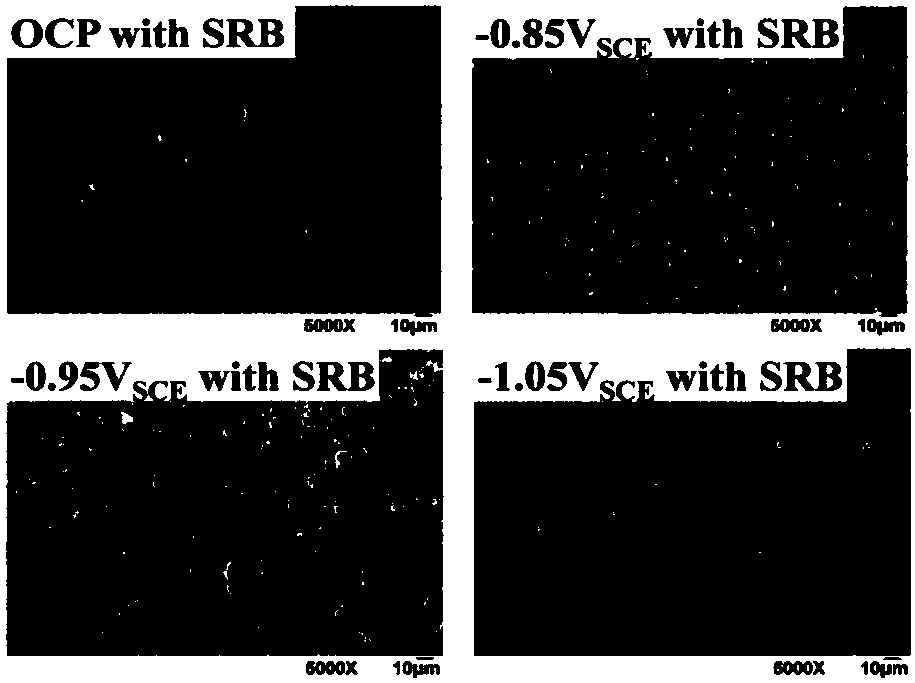

Embodiment 3

[0042] Observation of corrosion morphology of high-strength steel after removal of corrosion products under different cathodic protection potentials in anaerobic environment of sulfate-reducing bacteria.

[0043] Take out the test piece that has not been subjected to potentiodynamic polarization in Example 1, and remove the corrosion products according to the national standard GB / T16545-1996. The specific steps are as follows:

[0044] 1) Prepare cleaning solution: 500mL hydrochloric acid (HCl, ρ=1.19g / mL), 3.5g hexamethylene acid ammonium, add distilled water to prepare 1000mL solution.

[0045] 2) Take out the test piece that has not been subjected to potentiodynamic polarization in Example 1, put it into the cleaning solution configured in 1), and wash it at 20-25°C for 10 minutes, and the time can be extended according to the actual situation.

[0046] Corrosion morphology observation after removal of corrosion products was performed.

[0047] 3) Dry the test piece treate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com