Microcavity growth method based on nanocrystalline self-assembling

A growth method and self-assembly technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of high cost, large laser threshold, increased light loss, etc., and achieve high mode quality factor and good crystal quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

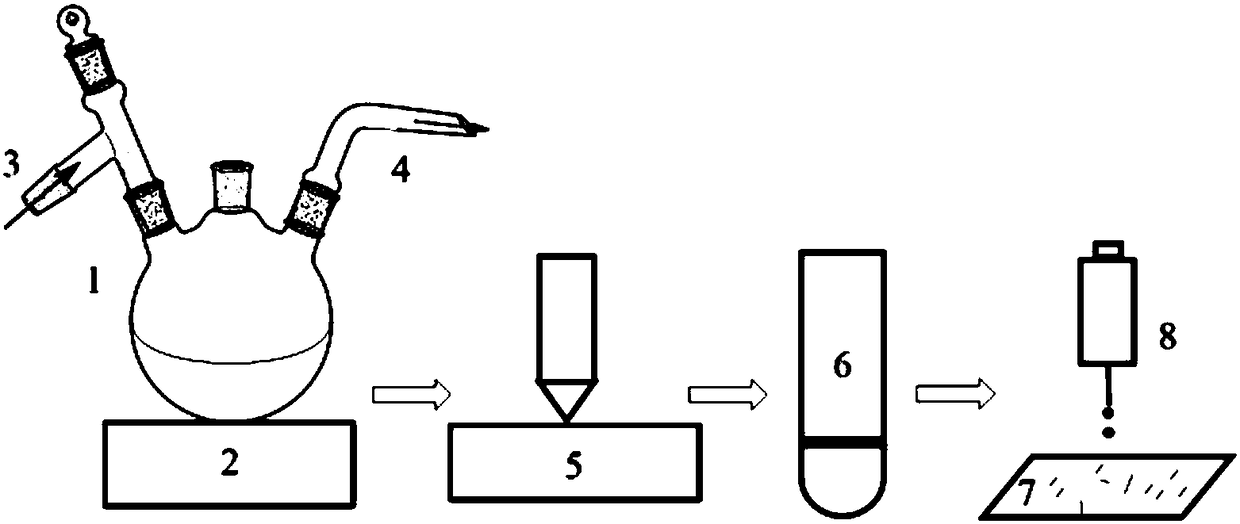

[0029] (1) 4ml octadecene, 1ml oleylamine, 0.5ml oleic acid, 69mg PbBr 2 Add it into a three-necked flask, degas the said three-necked flask containing raw materials at 100°C for 10 minutes, and continue to mix thoroughly at 100°C for 30 minutes, then raise the temperature to 180°C in an Ar gas atmosphere and keep it for 10 minutes.

[0030] (2) 0.4ml of cesium oleate was quickly injected into the three-neck flask, and after 5s, it was rapidly cooled in an ice-water bath at 0°C. CsPbBr 3 The quantum dots have an average size of 10 nm, and after centrifugation, they are dissolved in toluene at a concentration of 10 mg / ml.

[0031] (3) Take 1ml of the 10mg / ml quantum dots and put them in a brown vial to avoid light and deposit at 4°C.

[0032] (4) After 15 days, use a syringe to absorb a small amount of deposited quantum dots and drop them on a clean silicon wafer. The toluene will evaporate naturally, and any vibration should be avoided during the whole process.

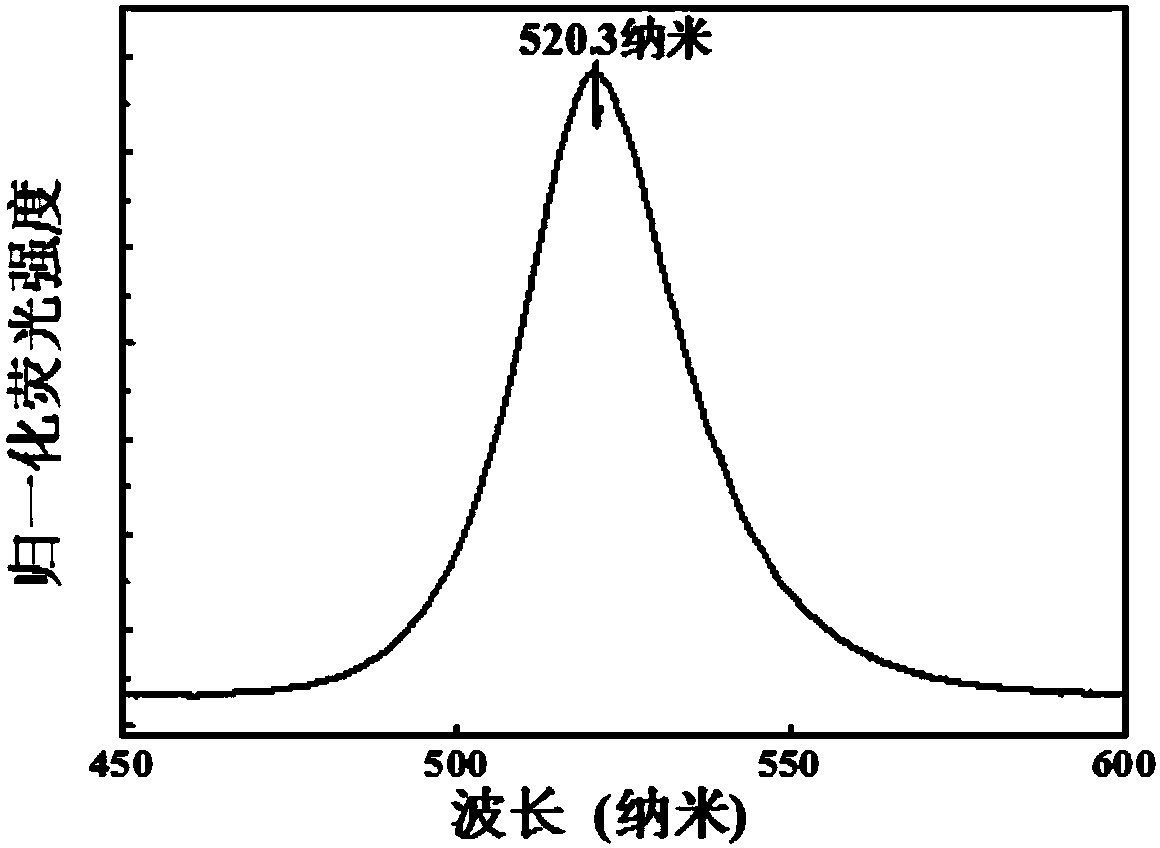

[0033] Qua...

Embodiment 2

[0035] This embodiment mainly refers to the preparation process of rectangular microsheets, the reaction temperature in the preparation process of quantum dots, the amount of oleylamine added, the solvent of quantum dots, the concentration of quantum dots, the deposition temperature, the deposition time, and the influence of the substrate on the formation process. The specific implementation process refers to Example 1. The difference is that the reaction temperature, the amount of oleylamine added, the quantum dot solvent, the deposition temperature, and the substrate were changed respectively during the preparation of quantum dots. The specific experimental parameters are shown in Table 1.

[0036] Table 1 The embodiment conditions of the preparation method of the rectangular sheet microcavity of the present invention

[0037]

[0038] Experiments show that changing the reaction temperature in the preparation process of quantum dots is from 170°C to 190°C. The higher the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com