gamma-Al2O3 carrier preparation method, and alkane isomerization catalyst preparation method

An alkane isomerization and catalyst technology, which is applied in physical/chemical process catalysts, catalyst carriers, and refined hydrocarbon oils, etc., can solve the problems of affecting catalyst activity, large pore size of alumina, and wide distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A more suitable preparation method is to volatilize the acidic alcohol solution of aluminum to generate alumina gel. Suitable acids include hydrochloric acid, sulfuric acid, nitric acid and the like, with hydrochloric acid and nitric acid being preferred. Suitable alcohols include methanol, ethanol, propanol, isopropanol, isobutanol, and the like, with ethanol and isopropanol being most preferred. Suitable aluminum precursors are aluminum chloride, aluminum nitrate, aluminum sulfate, aluminum isopropoxide and the like, most preferably aluminum nitrate and aluminum isopropoxide. The above solution is volatilized for several hours, and the selection of volatilization time should be determined according to the effect of forming a gel.

[0047] After the volatilization is completed, then wash, filter, and repeat several times to remove most of the impurity SO 4 2- (or Cl - ), Na + . The washed gel is dried at 50-150°C according to the general method. Crumble the drie...

Embodiment 1

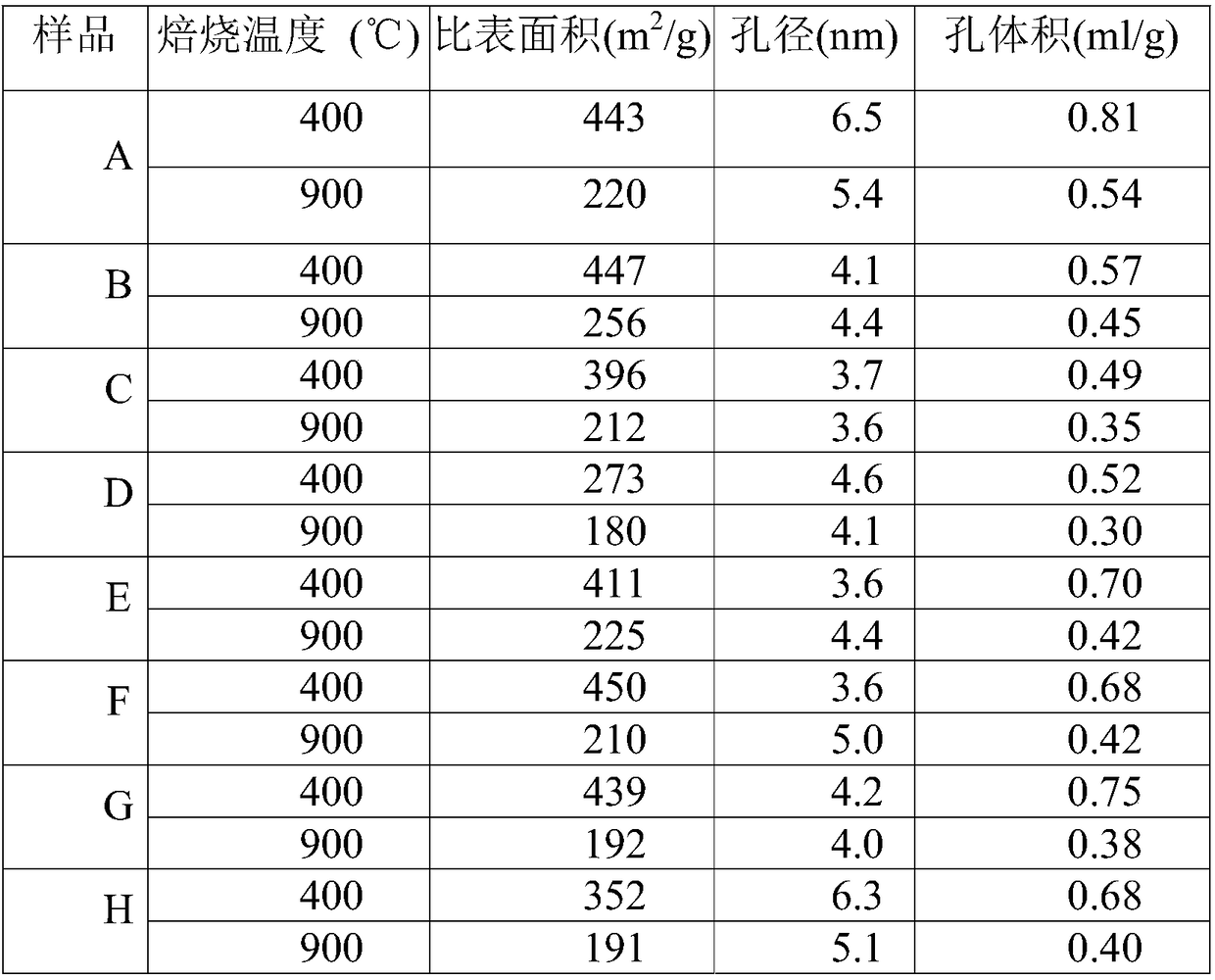

[0052] Dissolve 8g of triblock copolymer in 200mL of ethanol, add 15mL of 67w% nitric acid, weigh 25g of aluminum isopropoxide and stir at room temperature for 5 hours or longer until completely dissolved. After the dissolution was complete, it was transferred to a blast drying oven, and the temperature was set at 80°C. Under this condition, the solvent was evaporated, and the solution turned into a yellow solid. After 48 hours, the samples were removed. Wash the alumina gel, the washing temperature is the same as the stirring temperature, and the pH is controlled to remove the impurity SO 4 2- (or Cl - ), Na + . After washing, the alumina filter cake slurry was dried at 100°C, and the solution turned into a bright yellow solid. Crumble the dried alumina dry glue through a 200-mesh sieve, add glue solution, and extrude into strips or other shapes. Transfer to a porcelain crucible, and bake at 500°C for 6h in an air atmosphere to remove the template agent. The alumina th...

Embodiment 2

[0054] The operation method is the same as that of Example 1, except that the acid added is 15 mL of 37w% hydrochloric acid, and the solution turns into a white solid after the solvent is volatilized in an air-blast drying oven at 80°C for 48 hours. γ-Al 2 o 3 Carrier B. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com