Compound and liquid crystal composition thereof, and applications of liquid crystal composition

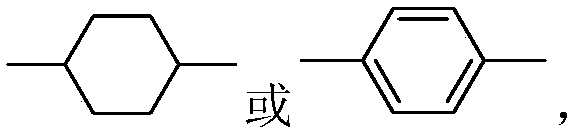

A compound and cyclic structure technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of slow response time, difficult driving, and low transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

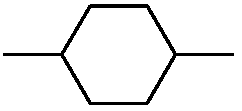

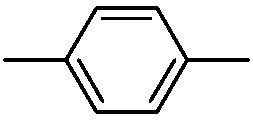

Method used

Image

Examples

Embodiment 1

[0087] Compound 1-(4-methoxy-butoxy)-4-(4-propyl-cyclohexyl)phenyl (No.2(R 1 =-C 3 h 7 , R=-CH 3 ), note: the numbering sees the following table 2, the same below) the synthetic route is as follows:

[0088]

[0089] Its specific preparation process is as follows:

[0090] Into a 500ml three-necked flask, add 2.18g propylcyclohexylphenol, 100ml anhydrous dimethylformamide (DMF), 2.76g anhydrous potassium carbonate, 0.15g potassium iodide, 1.4g 4-chlorobutyl methyl ether, stir at 90°C for 6h, After the completion of the reaction, post-treatment, purification by column chromatography, to obtain 2.5g white solid, compound No.2 (R 1 =-C 3 h 7 , R=-CH 3 ), GC>99%, yield: 91%.

[0091] MS: 55 (11%) 87 (100%) 107 (8.9%) 120 (10%) 133 (7.8%).

Embodiment 2

[0093] Compound 2,3-difluoro-4-(4-methoxy-butoxy)-4'-(4-propyl-cyclohexyl)-1,1'-biphenyl (No.66(R 1 =-C 3 h 7 , R=-CH 3 )) The synthetic route is as follows:

[0094]

[0095] Its specific preparation process is as follows:

[0096] 1. Synthesis of Compound M4

[0097]In a 500ml three-necked flask, add 5.1g 4-iodo-2,3-difluorophenol, 150ml anhydrous dimethylformamide (DMF), 5.5g anhydrous potassium carbonate, 0.3g potassium iodide, 2.8g 4-chlorobutyl methyl ether , stirred at 90°C for 6h, after the reaction was completed, post-treatment, and purified by column chromatography to obtain 6.6g of white solid, compound M4, GC>97%, yield: 97%.

[0098] 2. Compound No.66(R 1 =-C 3 h 7 , R=-CH 3 )Synthesis

[0099] In a 500ml three-necked flask, add 3.4g compound M4, 2.5g propylcyclohexylbenzeneboronic acid, 80ml toluene, 40ml ethanol, 40ml water, 4.2g anhydrous sodium carbonate, under nitrogen protection, add 0.1g tetrakis (triphenylphosphine) Palladium, heated and stir...

Embodiment 3

[0102] Compound 2',3'-difluoro-4-(4-methoxy-butoxy)-4"-propyl-1,1',4',1"-terphenyl (No.76(R 1 =-C 3 h 7 , R=-CH 3 )) The synthetic route is as follows:

[0103]

[0104] Its specific preparation process is as follows:

[0105] 1. Synthesis of Compound M7

[0106] In a 500ml three-necked flask, add 4.4g 4-iodophenol, 150ml anhydrous dimethylformamide (DMF), 5.5g anhydrous potassium carbonate, 0.3g potassium iodide, 2.8g 4-chlorobutyl methyl ether, stir at 90°C for 6h, and react After completion, post-processing, purification by column chromatography, to obtain 5.7g of white solid, compound M7, GC>97%, yield: 93%.

[0107] 2. Compound No.76 (R 1 =-C 3 h 7 , R=-CH 3 )Synthesis

[0108] In a 500ml three-necked flask, add 3.1g compound M7, 2.8g propyl difluorobiphenylboronic acid, 80ml toluene, 40ml ethanol, 40ml water, 4.2g anhydrous sodium carbonate, under nitrogen protection, add 0.1g tetrakis (triphenylphosphine ) palladium, heated and stirred to reflux 6h, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com