Cyanide-free white copper tin electroplating solution and preparation method thereof

A preparation method and electroplating solution technology are applied in the field of cyanide-free cupronickel tin electroplating solution and its preparation, and can solve the problems of poor electroplating quality, instability of the electroplating solution, inability to realize mass production and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1.1 Plating solution preparation

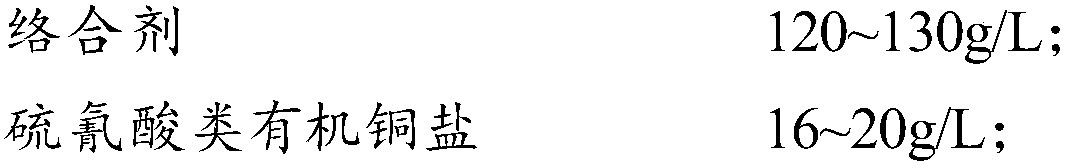

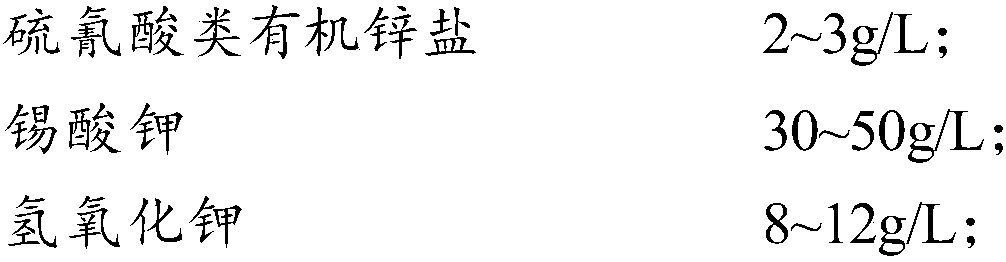

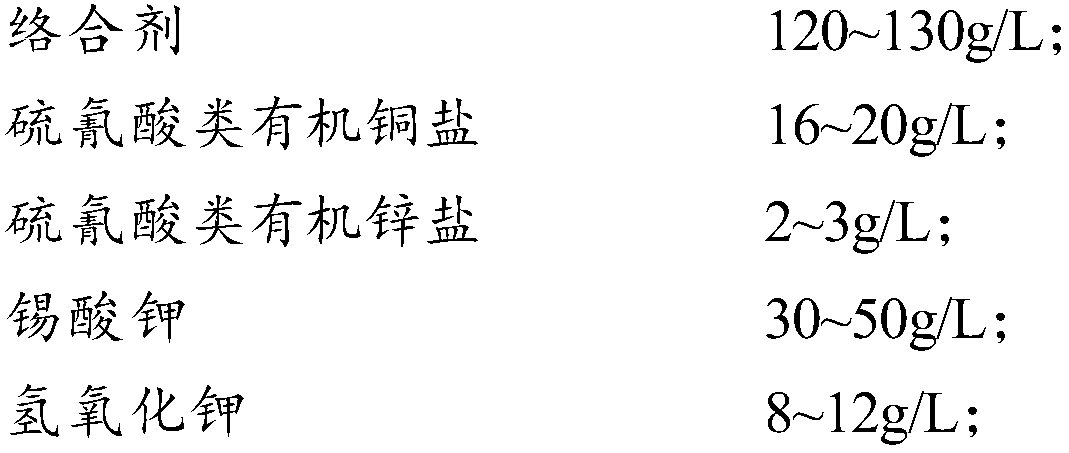

[0059] raw material:

[0060] Complexing agent Polymerized potassium ammonium thiocyanate (m=2, n=2) 122g / L, polymerized cuprous thiocyanate (m=2, n=2) 17g / L, polymerized zinc thiocyanate (m=1 , n=2) 2.2g / L, potassium stannate 38g / L, potassium hydroxide 9g / L, water as solvent.

[0061] Preparation:

[0062] Add complexing agent to water accounting for 50% of the total water volume, heat up to 50°C, stir and dissolve evenly, add zinc salt, stir while adding until zinc salt is completely dissolved, then add copper salt, stir while adding until copper salt Completely dissolve to obtain the main solution; add potassium hydroxide and potassium stannate to the obtained main solution, stir well, add the remaining water to the full amount, filter with activated carbon adsorption, and obtain the electroplating solution (PH value is 13.5).

[0063] 1.2 Electroplating test

[0065] Add 250mL electroplating soluti...

Embodiment 2

[0079] 1.1 Plating solution preparation

[0080] raw material:

[0081] Complexing agent polymerized potassium ammonium thiocyanate (m=20, n=20) 128g / L, polymerized cuprous thiocyanate (m=20, n=20) 17.5g / L, polymerized zinc thiocyanate (m= 10, n=20) 2.5g / L, potassium stannate 40g / L, potassium hydroxide 9.5g / L, water as solvent.

[0082] Preparation:

[0083] Add complexing agent to water accounting for 50% of the total water volume, heat up to 50°C, stir and dissolve evenly, add zinc salt, stir while adding until zinc salt is completely dissolved, then add copper salt, stir while adding until copper salt Completely dissolve to obtain the main solution; add potassium hydroxide and potassium stannate to the obtained main solution, stir well, add the remaining water to the full amount, filter with activated carbon adsorption, and obtain the electroplating solution (PH value is 13.5).

[0084] 1.2 Electroplating test

[0086] Add 250mL electroplat...

Embodiment 3

[0092] 1.1 Plating solution preparation

[0093] raw material:

[0094] Complexing agent polymerized potassium ammonium thiocyanate (m=30, n=30) 130g / L, polymerized cuprous thiocyanate (m=30, n=30) 20g / L, polymerized zinc thiocyanate (m=15 , n=30) 3g / L, potassium stannate 50g / L, potassium hydroxide 12g / L, and water as a solvent.

[0095] Preparation:

[0096] Add complexing agent to water accounting for 50% of the total water volume, heat up to 50°C, stir and dissolve evenly, add zinc salt, stir while adding until zinc salt is completely dissolved, then add copper salt, stir while adding until copper salt Completely dissolve to obtain the main solution; add potassium hydroxide and potassium stannate to the obtained main solution, stir well, add the remaining water to the full amount, filter with activated carbon adsorption, and obtain the electroplating solution (PH value is 13.5).

[0097] 1.2 Electroplating test

[0099] Add 250mL electropla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com