Low-smoke non-toxic soldering flux for circuit board soldering

A flux and circuit board technology, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of smoke, unpleasant smell, harm to the health of welding operators, avoid corrosion and improve reliability , Improve the effect of unpleasant odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

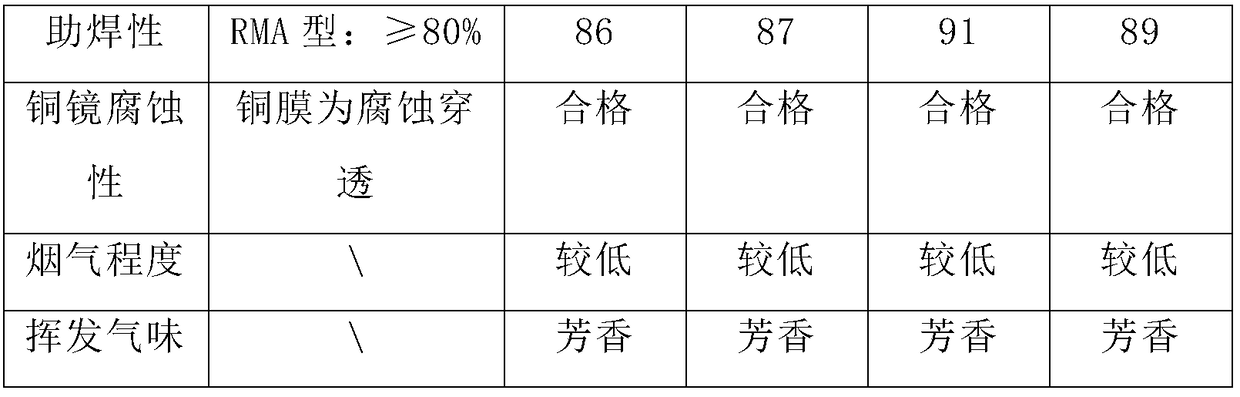

Embodiment 1

[0019] A low-smoke non-toxic flux for circuit board soldering. According to the mass parts, the composition of the flux includes: 80 parts of low-smoke modified rosin, 6 parts of hydrogenated rosin methyl ester, 3 parts of zinc chloride, 2 parts of ammonium chloride 5 parts of hydrochloric acid, 1 part of polyglycol, 3 parts of glycerin, 2 parts of citric acid, 15 parts of organic solvent, 1 part of co-solvent, 2 parts of lubricant, 4 parts of thixotropic agent, and 3 parts of fragrance.

[0020] Among them, the preparation method of low-smoke modified rosin is as follows: rosin resin and cyclohexane are added to the reactor according to the mass ratio of 3:1, dissolved at a temperature of 150 ° C, and the nickel-based catalyst is added to the reactor. Simultaneously vacuumize the inside of the reactor, then fill the reactor with hydrogen, keep the pressure in the reactor at 8MPa, react for 3h, depressurize the reactor after the reaction, and remove the residual cyclohexane by ...

Embodiment 2

[0024] A low-smoke non-toxic flux for circuit board soldering. According to parts by mass, the composition of the flux includes: 90 parts of low-smoke modified rosin, 10 parts of hydrogenated rosin methyl ester, 6 parts of zinc chloride, and 5 parts of ammonium chloride 7 parts of hydrochloric acid, 2 parts of polyglycol, 5 parts of glycerin, 4 parts of citric acid, 20 parts of organic solvent, 3 parts of co-solvent, 3 parts of lubricant, 7 parts of thixotropic agent, and 5 parts of fragrance.

[0025] Among them, the preparation method of low-smoke modified rosin is as follows: rosin resin and cyclohexane are added to the reactor according to the mass ratio of 3:1, dissolved at a temperature of 180 ° C, and the nickel-based catalyst is added to the reactor. Simultaneously vacuumize the inside of the reactor, then fill the reactor with hydrogen, keep the pressure in the reactor at 10MPa, react for 5h, depressurize the reactor after the reaction, and remove the residual cyclohex...

Embodiment 3

[0029] A low-smoke non-toxic flux for circuit board soldering. According to the mass parts, the composition of the flux includes: 85 parts of low-smoke modified rosin, 8 parts of hydrogenated rosin methyl ester, 4 parts of zinc chloride, 3 parts of ammonium chloride 6 parts of hydrochloric acid, 1.5 parts of polyglycol, 4 parts of glycerin, 3 parts of citric acid, 17 parts of organic solvent, 2 parts of cosolvent, 2.5 parts of lubricant, 6 parts of thixotropic agent, and 4 parts of aromatic agent.

[0030] Among them, the preparation method of low-smoke modified rosin is as follows: rosin resin and cyclohexane are added to the reactor according to the mass ratio of 3:1, dissolved at a temperature of 165 ° C, and the nickel-based catalyst is added to the reactor. Simultaneously vacuumize the inside of the reactor, then fill the reactor with hydrogen, keep the pressure in the reactor at 9MPa, react for 4h, depressurize the reactor after the reaction, and remove the residual cyclo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com