Salt pan technology for separating ingredients by temperature differences

A technology of salt field and temperature difference, which is applied in the fields of bisulphate preparation, alkali metal sulphite/sulphite, inorganic chemistry, etc. It can solve the problems of not reaching the predicted value, difficult to recycle, and difficult to evaporate brine, etc. Achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

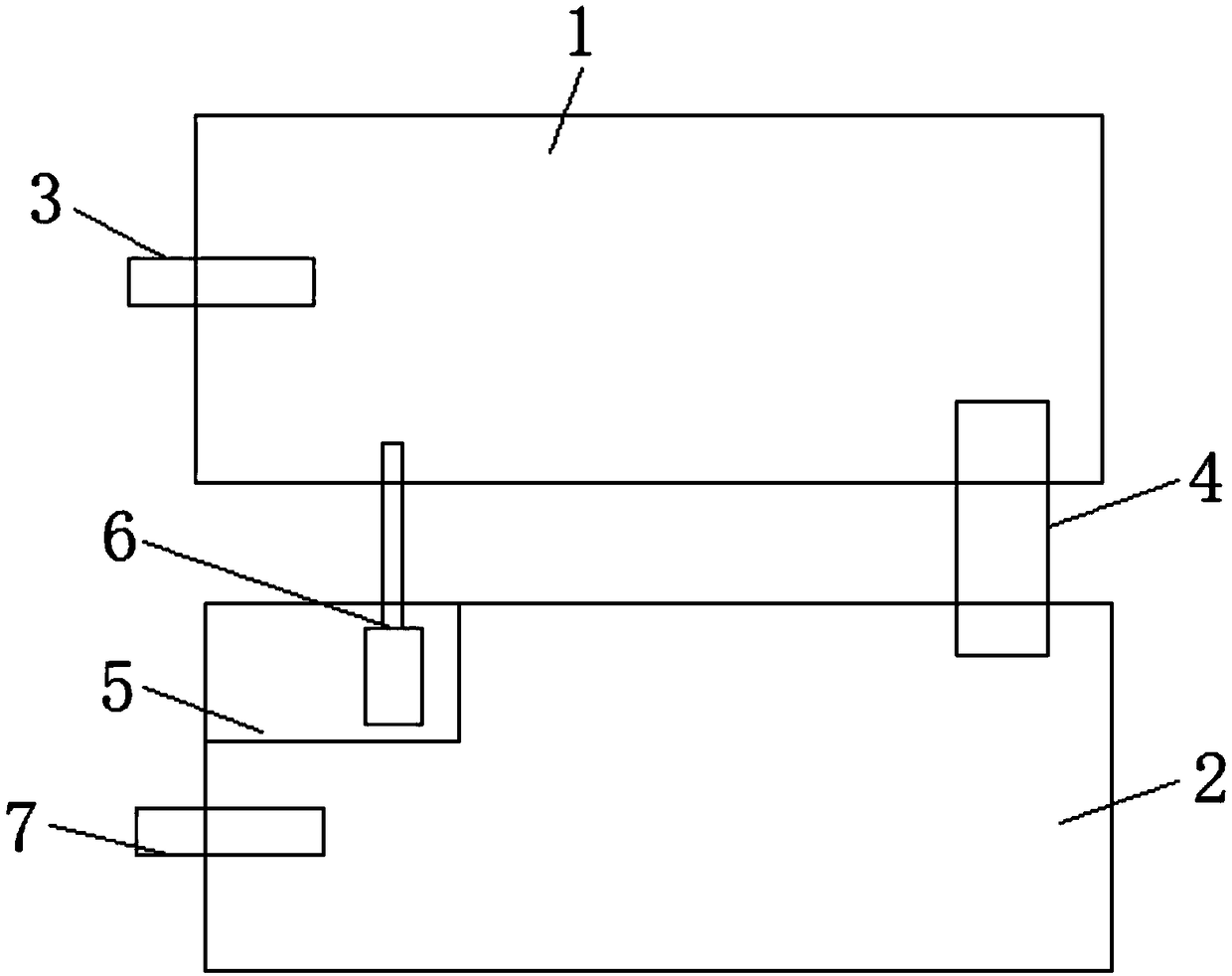

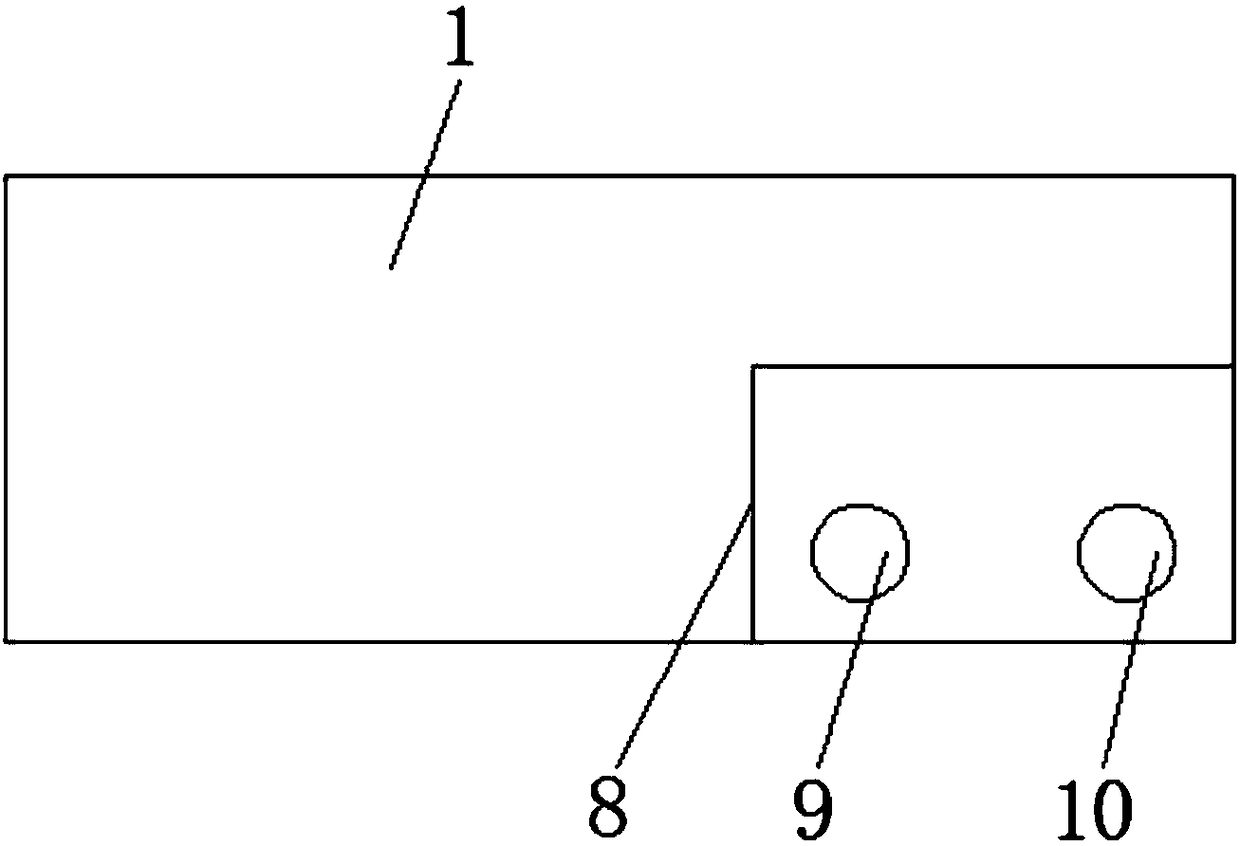

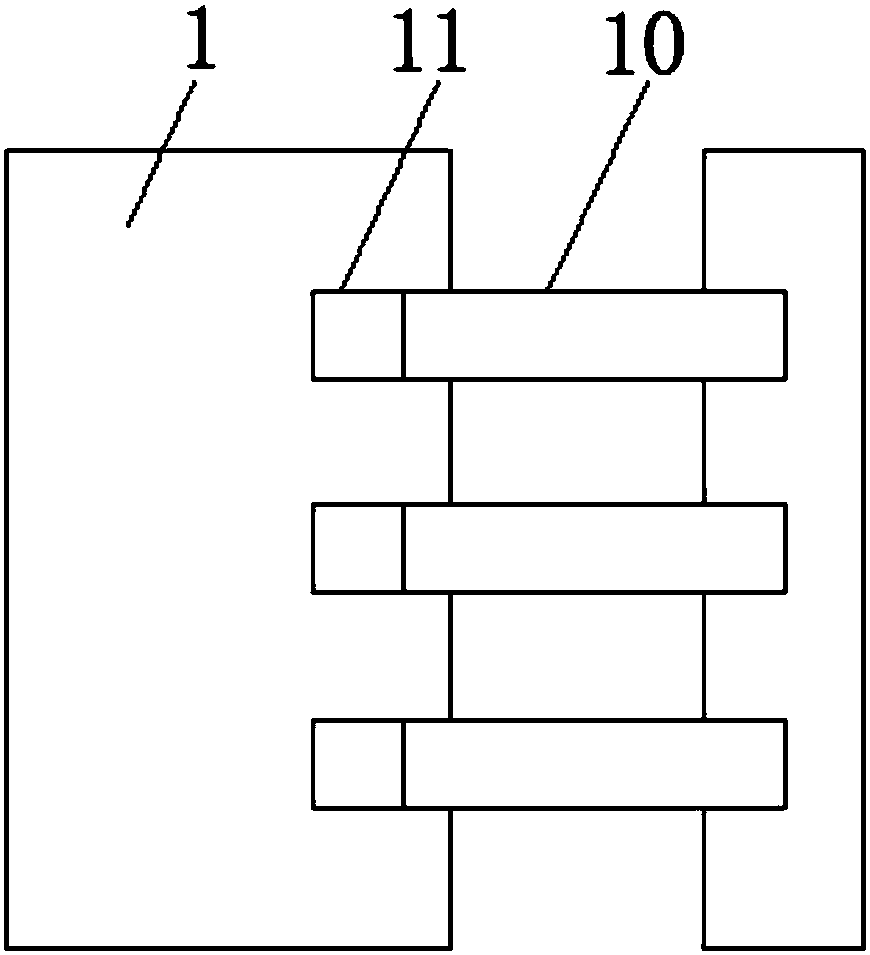

Method used

Image

Examples

example 1

[0067] Example 1: Using a certain brine, the quality of brine is shown in the following table:

[0068] Table 2 Raw brine quality status table

[0069]

[0070] When the brine evaporates to the following extent, there is no evaporation phenomenon in the brine, and it is accompanied by other phenomena

[0071] Table 3 The simple solarization process can control the quality status of brine to the best point

[0072]

[0073] At this time, the brine has become solid at night and liquid at noon during the day, and by measuring the specific evaporation coefficient, it can be seen that the brine has no evaporation phenomenon, and the small-scale experiment of simulating a conventional simple salt field does not know how to operate: all operations are conventional simple salt fields Not achievable.

[0074] After using the temperature difference between morning and evening to separate bischofite, the brine will continue to be sun-dried, and finally the composition of higher-q...

example 2

[0085] Example 2: Opinions on the production of potassium mixed salt from sulfate-type brine

[0086] A certain salt lake belongs to sulfate-type brine, and the evaporation route is (rock salt—rock salt + epsomite——rock salt + epsom salt+carnallite—rock salt+carnallite+bischroite—— halite + bischofite).

[0087] In the development and utilization of the salt lake, it was found that due to the Epsom salt (MgSO 4 ·7H 2 O) content is relatively large, and the local rainfall is relatively large, it is difficult for the actual brine evaporation to enter the carnallite stage, and the development of this salt lake has always lagged behind the development of other salt lakes.

[0088] In the salt field test stage, we found that every night-morning, a lot of epsom salt crystallized on the salt field (rock ore identification), and in the morning-noon-afternoon stage, the epsom salt disappeared (redissolved into the brine), In this way, it is quite difficult for the brine to evaporate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com