Sludge carbonization all-in-one machine and method

An integrated machine and sludge technology, applied in chemical instruments and methods, sludge treatment, pyrolysis treatment of sludge, etc., can solve the problems of limited reduction effect, no major breakthrough in industry development, lack of technology, etc. Biodegradability, significant reduction effect, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

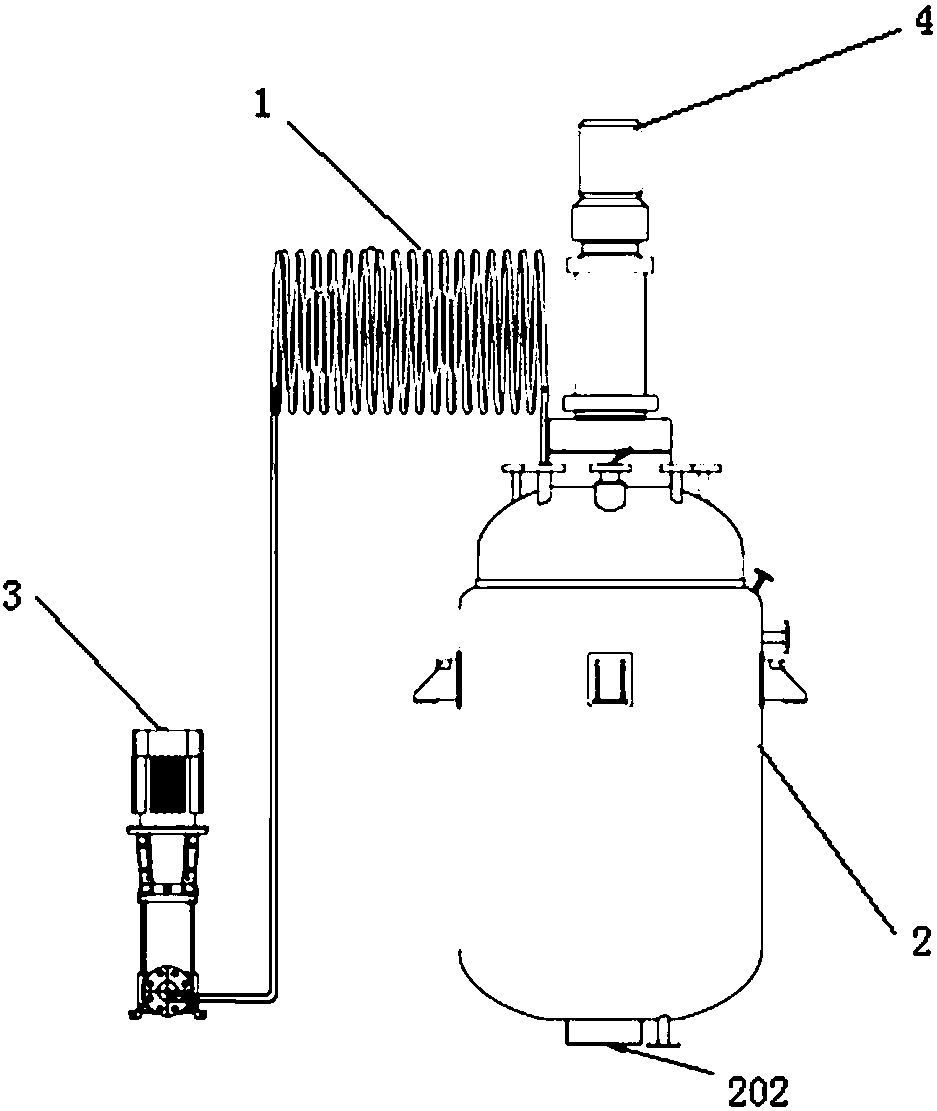

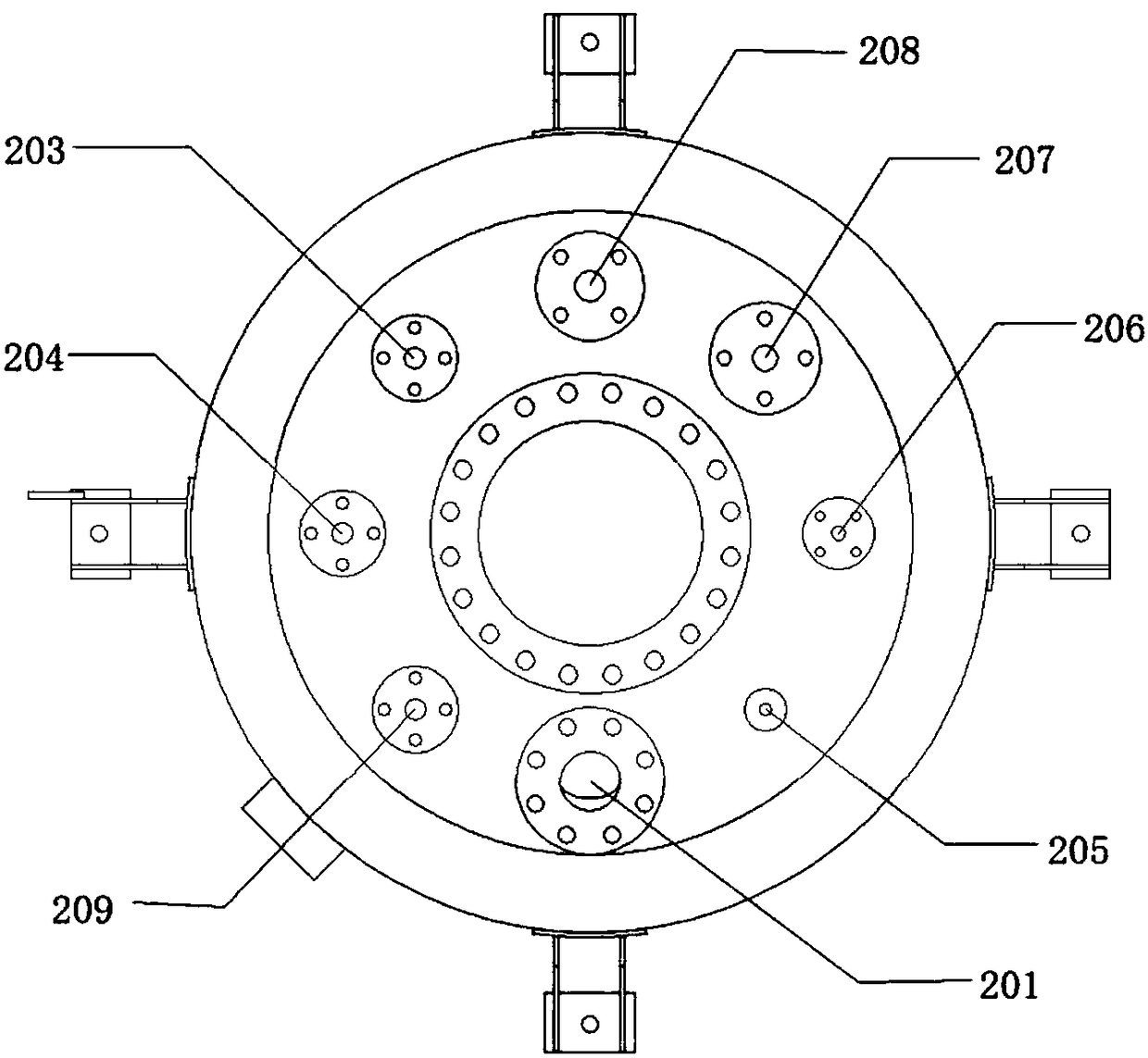

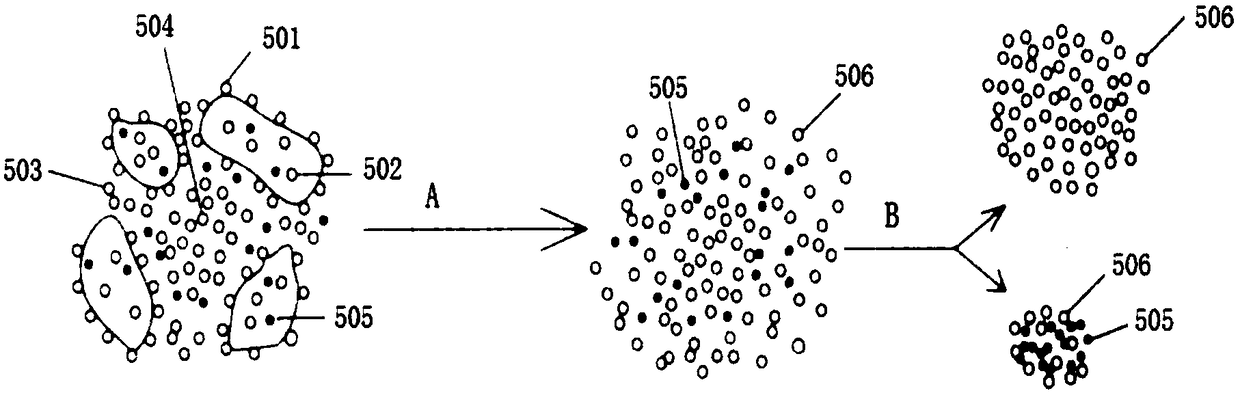

Embodiment 1

[0021] The municipal sludge with a water content of 80% is transported to the pipeline-transported heating unit through the sludge pump 3, and heated during the transport of the sludge to a temperature of 120-150°C. The sludge enters the pressurized part of the reaction kettle from the pipeline conveying heating part through the sludge pump, and at the same time, the waste gas, steam and sludge generated during heating are continuously pumped out by using the vacuum tank to connect the suction port 204. After all the sludge enters, the valve is closed, and the drive motor 4 is The valve in the reaction kettle 2 provides power, and nitrogen gas is fed into the reaction kettle to continuously increase the pressure to 12-22MPa, so that the biomass in the sludge is cracked and the water in it is released. The reacted sludge is discharged from the discharge port 202, and 75% of the water in the sludge can be removed by ordinary mechanical dehydration to obtain biochar, which can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com