Preparation method of enoxaparin sodium crude product

A technology of enoxaparin sodium and heparin sodium, which is applied in the field of preparation of crude enoxaparin sodium, can solve problems such as uneven degradation of esterified products, unstable quality, deep product color, etc., and achieve suitable molecular weight range, good decolorization effect, The effect of high product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

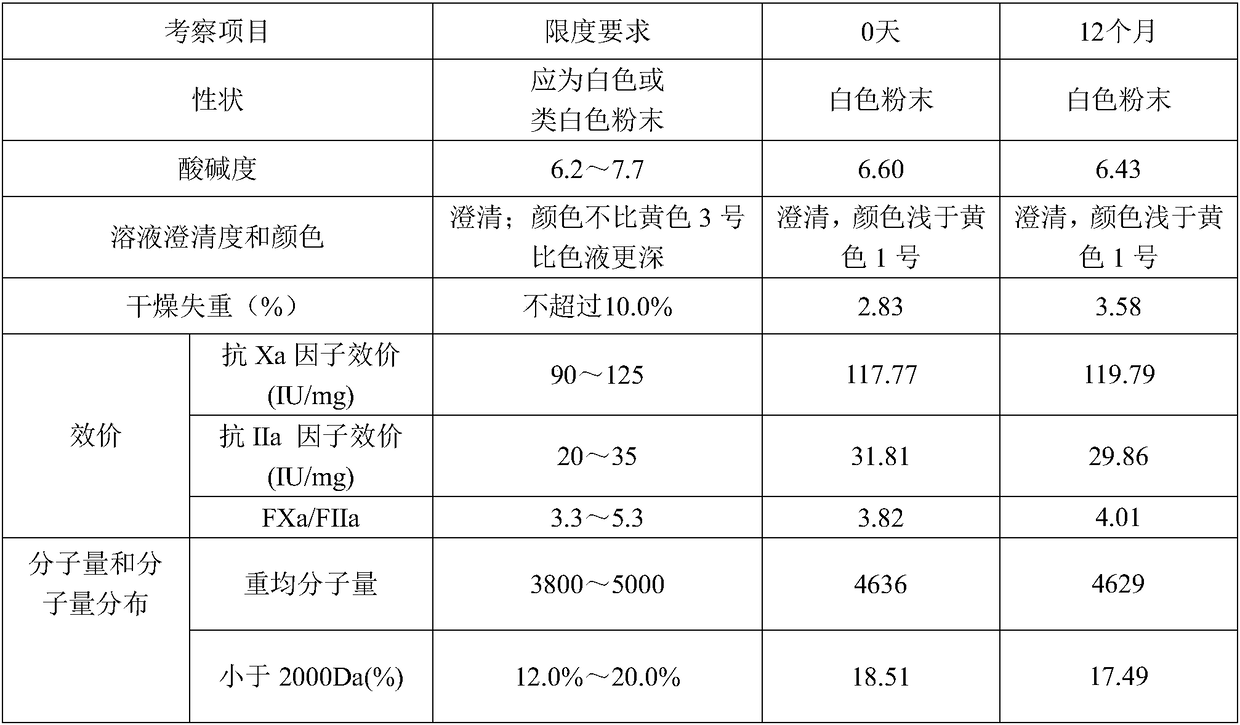

Embodiment 1

[0021] 2.5 parts by weight of benzethonium chloride are dissolved in 5 parts by weight of purified water to form a benzethonium chloride solution; 1 part by weight of heparin sodium is dissolved in 13 parts by weight of purified water to form a sodium heparin solution, and the The benzethonium chloride solution was added to the sodium heparin solution at room temperature. After the addition, the reaction was stirred at room temperature for 3 h, filtered with suction, the filter cake was washed with water for 3 times, dried in vacuum, and dried under vacuum at 50° C. to obtain a heparin quaternary ammonium salt solid.

[0022] Dissolve 1 part by weight of heparin quaternary ammonium salt in 11 parts by volume of dichloromethane, add 2 parts by weight of benzyl chloride, react at 40°C for 25 hours, cool to room temperature, add 2 parts by weight of sodium acetate under stirring The prepared 10% sodium acetate methanol solution was stirred for 40 minutes, left to settle for 3 hou...

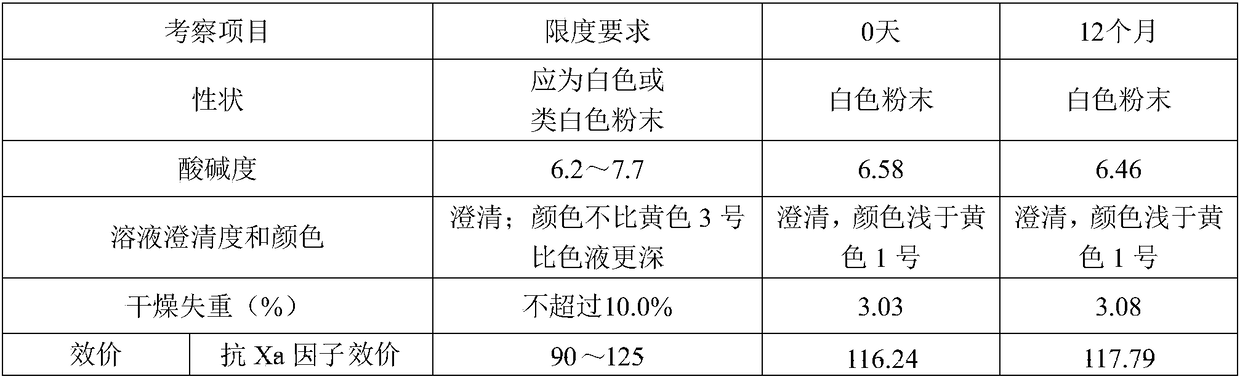

Embodiment 2

[0029] Dissolve 2.2 parts by weight of benzethonium chloride in 4.5 parts by weight of purified water to form a benzethonium chloride solution; dissolve 1 part by weight of heparin sodium in 12 parts by weight of purified water to form a heparin sodium solution, and slowly dissolve the The benzethonium chloride solution was added to the sodium heparin solution at room temperature. After the addition, the reaction was stirred at room temperature for 2 h, filtered with suction, the filter cake was washed with water three times, dried in vacuum, and dried under vacuum at 45° C. to obtain a heparin quaternary ammonium salt solid.

[0030] Dissolve 1 part by weight of heparin quaternary ammonium salt in 9 times the volume of dichloromethane, add 2 parts by weight of benzyl chloride, react at 30°C for 21 hours, cool to room temperature, add 2 parts by weight of sodium acetate under stirring The prepared 10% sodium acetate methanol solution was stirred for 20 minutes, left to settle ...

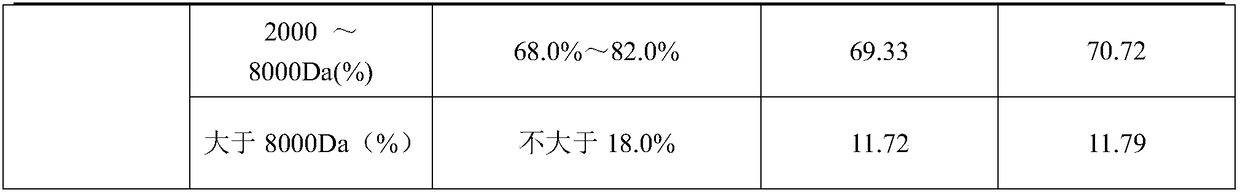

Embodiment 3

[0037] 2.8 parts by weight of benzethonium chloride are dissolved in 5.5 parts by weight of purified water to form a benzethonium chloride solution; 1 part by weight of heparin sodium is dissolved in 14 parts by weight of purified water to form a sodium heparin solution, and the The benzethonium chloride solution was added to the sodium heparin solution at room temperature. After the addition was completed, the reaction was stirred at room temperature for 4 h, filtered with suction, the filter cake was washed with water for 3 times, dried in vacuum, and dried under vacuum at 55° C. to obtain a heparin quaternary ammonium salt solid.

[0038] Dissolve 1 part by weight of heparin quaternary ammonium salt in 13 parts by volume of dichloromethane, add 2 parts by weight of benzyl chloride, react at 35°C for 23 hours, cool to room temperature, add 2 parts by weight of sodium acetate under stirring The prepared 10% sodium acetate methanol solution was stirred for 30 minutes, left to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com