A lignosulfonate dispersed self-healing polyurea coating and its preparation method, coating and application

A lignosulfonate, self-healing technology, used in lignin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor epoxy resin flexibility, easy cracking, poor low temperature flexibility, etc. Inexpensive, abundant sources, overcoming difficult-to-repair effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

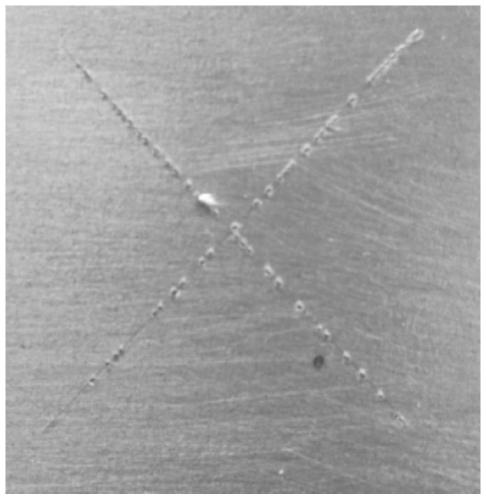

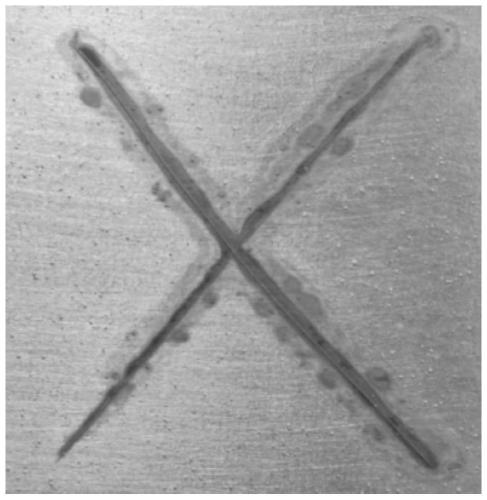

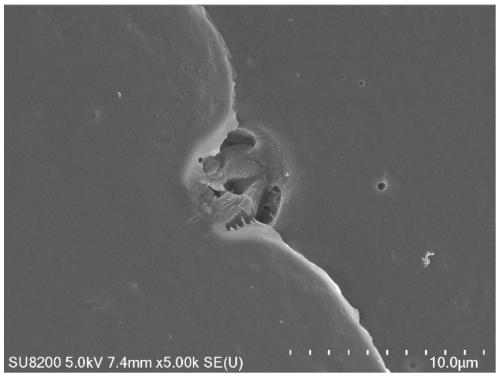

Examples

Embodiment 1

[0049] (1) After the 2% wheat straw pulp sodium lignosulfonate of 10g is added to the 30mL white lid glass sample, in the sample bottle, add the PMDI of 0.5g and the IPDI of 2.5g that mix homogeneously, mechanically under 11000rpm / min rotating speed Emulsify for 3 minutes to obtain an O / W type pickering emulsion and set it aside.

[0050] (2) At room temperature, add 0.01mol amino-terminated polyether D-2000 and 0.012mol HDI to a 150mL beaker, raise the temperature of the water bath to 75°C (5°C / min) at a constant speed and react at 300rpm for 1h to obtain viscous and transparent HDI Prepolymer, wait for the prepolymer to cool down at room temperature.

[0051] (3) At room temperature, after adding the emulsion of step (1) to the prepolymer of step (2), add 0.001mol of a hindered amine chain extender dissolved in 1mL of toluene and 0.05mol of amino-terminated polyether D-2000, Mechanically stirred at 300 rpm for 1 h.

[0052] (4) Polish the steel sheet with sandpaper, rinse ...

Embodiment 2

[0056] (1) After adding 6g of 0.5% wheat straw pulp sodium lignosulfonate to a 30mL glass sample with a white lid, add 1g of MDI and 5g of IPDI to the sample bottle, and mechanically emulsify at 11000rpm / min for 30s , to obtain an O / W type pickering emulsion.

[0057] (2) At room temperature, add 0.01mol amino-terminated polyether D-2000 and 0.012mol HDI to a 150mL beaker, raise the temperature of the water bath to 45°C (5°C / min) at a constant speed and react at 200rpm for 1.5h to obtain viscous and transparent HDI prepolymer, wait for the prepolymer to cool down at room temperature.

[0058] (3) At room temperature, after adding the emulsion of step (1) to the prepolymer of step (2), add 0.001mol of a hindered amine chain extender dissolved in 1mL of toluene and 0.05mol of amino-terminated polyether D-2000, Mechanically stir at 200rpm for 30min.

[0059] (4) Polish the steel sheet with sandpaper, rinse with acetone and dry. The compound in step (3) was coated on the steel ...

Embodiment 3

[0062] (1) After the 1% bamboo pulp sodium lignosulfonate of 4g was added to the 30mL white cover glass sample, in the sample bottle, add the PMDI of 0.5g and the IPDI of 0.5g that mix homogeneously, mechanically under 11000rpm / min rotating speed Emulsify for 30s to obtain an O / W type pickering emulsion.

[0063] (2) At room temperature, add 0.01mol amino-terminated polyether D-2000 and 0.012mol HDI to a 150mL beaker, raise the temperature of the water bath to 60°C (5°C / min) at a constant speed, and stir mechanically at 300rpm for 1h to obtain viscous and transparent HDI Prepolymer, wait for the prepolymer to cool down at room temperature.

[0064] (3) At room temperature, after adding the emulsion of step (1) to the prepolymer of step (2), add 0.001mol of a hindered amine chain extender dissolved in 1mL of toluene and 0.05mol of amino-terminated polyether D-2000, Mechanical stirring was performed at 300 rpm for 40 min.

[0065] (4) Polish the steel sheet with sandpaper, rin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com