Method for purifying and removing chlorine by manganese sulfate electrolyte

A technology of electrolyte and manganese sulfate, which is applied in the field of purification and removal of chlorine in manganese sulfate solution, and in the field of hydrometallurgy. It can solve the problems of inability to be directly used as dechlorination agent, increase in treatment costs, sewage, etc., and achieve low production costs and high product quality. The effect of good quality and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

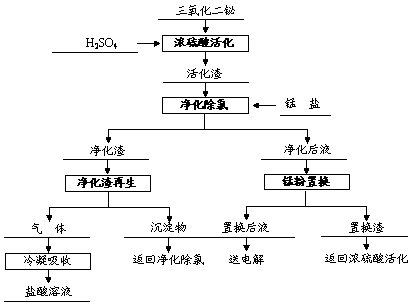

Image

Examples

Embodiment 1

[0029] Bi in bismuth trioxide described in the present invention 2 o 3 The mass percentage is not less than 99.90%, industrial grade concentrated sulfuric acid (H 2 SO 4 ≥98.0%), industrial grade manganese powder (Mn≥99.0%) and manganese carbonate (MnCO 3 ≥98.0%). Stir and mix bismuth trioxide and concentrated sulfuric acid according to the mass ratio of 1 / 4, then heat up to 210°C and react for 10 minutes, stop heating after the yellow bismuth trioxide turns into white precipitate, and add the activated slag to the manganese sulfate electrolysis In the liquid, control the ratio of the activated slag mass kg to the liquid volume L to be 1 / 120, keep stirring and keep the temperature at 70°C, add manganese carbonate at the same time to maintain the pH value of the solution at the initial value of 2.30, continue to stir and react for 1.0h, and use vacuum pumping Liquid-solid separation by filtration, the chlorine ion in the purified liquid is reduced to 22mg / L, and the chlorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com