Synthetic method for drug 7-(3,5,6-trimethyl-1,4-benzoquinon-2-yl)-7-phenylheptanoic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

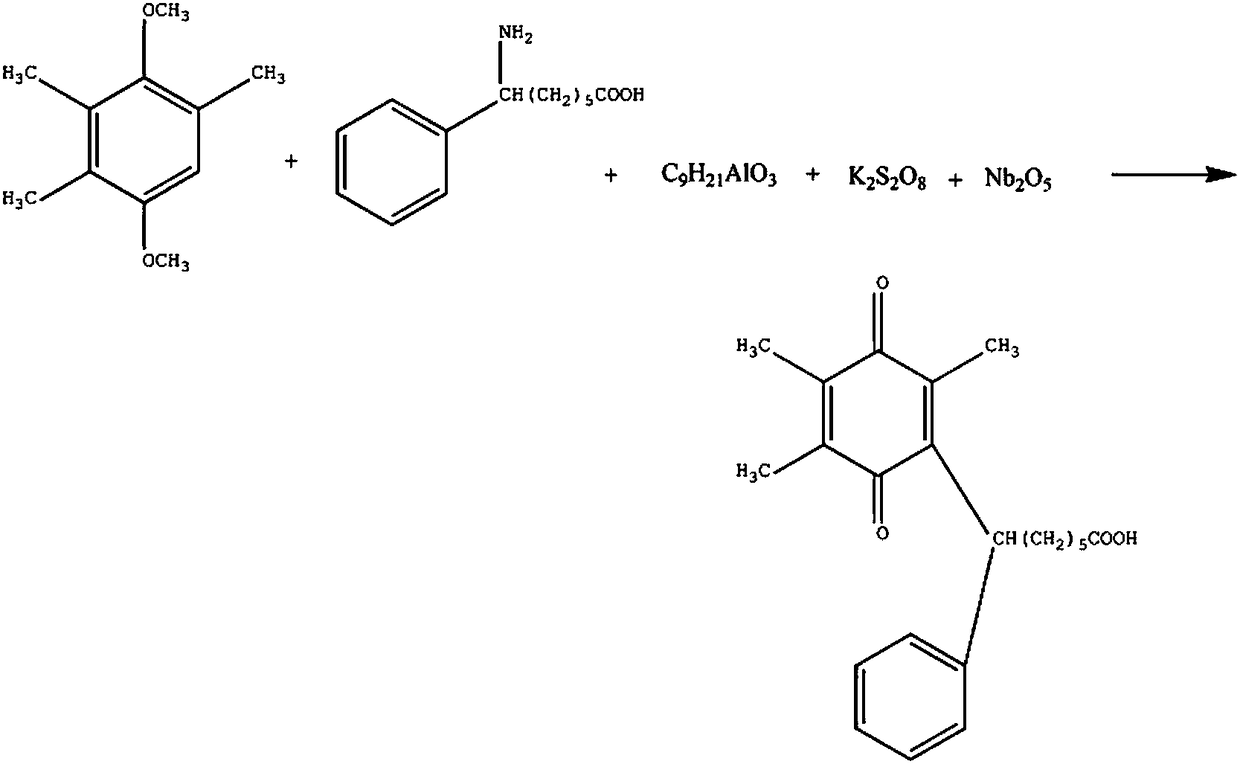

Image

Examples

Embodiment 1

[0016] 7-(3,5,6-trimethyl-1,4-benzoquinone-2-yl)-7-phenylheptanoic acid drug synthesis method, comprising the following steps:

[0017] A: Add 2mol 1,4-dimethoxy-2,5,6-trimethylbenzene into the reaction vessel, 700ml mass fraction is 10% sodium nitrate solution, control the stirring speed to 230rpm, raise the temperature to 40°C, Then add 4mol aluminum isopropoxide, continue to react for 1h;

[0018] B: Raise the temperature to 50°C, add 900ml of sodium sulfate solution with a mass fraction of 15%, add 3mol potassium peroxodisulfate twice within 30min, control the stirring speed to 330rpm, add 3mol niobium pentoxide within 20min powder, continue to react for 2 hours, lower the temperature to 4°C, add 1.3L of 20% potassium chloride solution with a mass fraction of Wash with 60% chloroform solution for 40 minutes, recrystallize anhydrous calcium sulfate dehydrating agent in 70% propargyl alcohol solution and dehydrate to obtain the finished product 7-(3,5,6-trimethyl-1,4-benzen...

Embodiment 2

[0020] 7-(3,5,6-trimethyl-1,4-benzoquinone-2-yl)-7-phenylheptanoic acid drug synthesis method, comprising the following steps:

[0021] A: Add 2mol 1,4-dimethoxy-2,5,6-trimethylbenzene into the reaction vessel, 700ml mass fraction is 13% sodium nitrate solution, control the stirring speed to 240rpm, raise the temperature to 44°C, Then add 5mol aluminum isopropoxide and continue the reaction for 1.5h;

[0022] B: Raise the temperature to 53°C, add 900ml of 19% sodium sulfate solution, add 4mol potassium peroxodisulfate in 3 times within 40min, control the stirring speed to 340rpm, add 4mol niobium pentoxide within 30min powder, continue to react for 2.5h, lower the temperature to 6°C, add 1.3L potassium chloride solution with a mass fraction of 23%, the solution is separated, and the oil layer is separated, washed with ethylene glycol solution with a mass fraction of 43% for 25min, and the mass fraction is Wash with 63% chloroform solution for 45 minutes, recrystallize anhydro...

Embodiment 3

[0024] 7-(3,5,6-trimethyl-1,4-benzoquinone-2-yl)-7-phenylheptanoic acid drug synthesis method, comprising the following steps:

[0025] A: Add 2mol 1,4-dimethoxy-2,5,6-trimethylbenzene into the reaction vessel, 700ml mass fraction is 16% sodium nitrate solution, control the stirring speed to 260rpm, raise the temperature to 47°C, Then add 6mol aluminum isopropoxide, continue to react for 2h;

[0026] B: Raise the temperature to 55°C, add 900ml of sodium sulfate solution with a mass fraction of 22%, add 5mol potassium peroxodisulfate in 4 times within 50min, control the stirring speed to 350rpm, add 5mol niobium pentoxide within 40min powder, continue to react for 3 hours, lower the temperature to 8°C, add 1.3L of potassium chloride solution with a mass fraction of 25%, the solution is separated, and the oil layer is separated. Wash with 65% chloroform solution for 50 minutes, recrystallize anhydrous calcium sulfate dehydrating agent in 77% propargyl alcohol solution for dehyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com