Synthetic method for vitamin drug intermediate diketogulonic acid

A technique for the synthesis of gulonic acid and its synthesis method, which is applied in the synthesis of diketone guluronic acid, a vitamin drug intermediate, and in the field of preparation of pharmaceutical intermediates, and can solve the problem of increased risk factor in the synthesis process, high requirements for corrosion resistance, and synthetic Problems such as complex process technology, etc., to achieve the effects of safe production, shortened reaction time, and improved reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

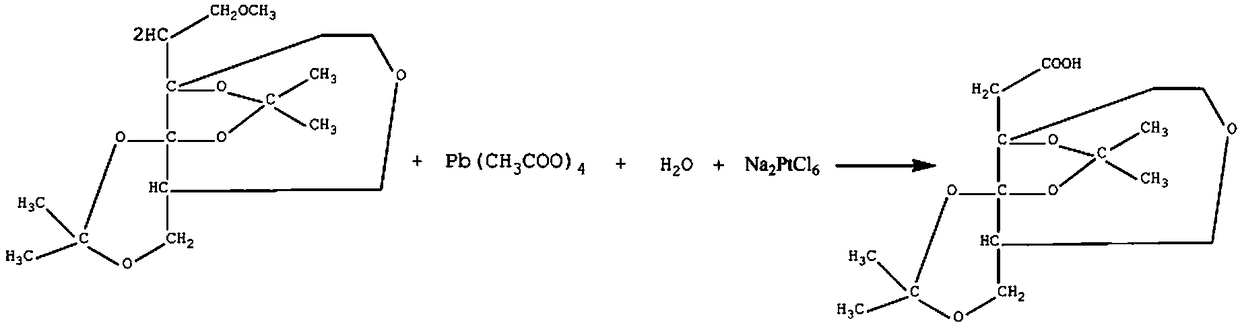

Image

Examples

Embodiment 1

[0015] The synthetic method of vitamin drug intermediate diketogulonic acid comprises the following steps:

[0016] A: Add 2mol 2,3,4,6-diketone sorbosyl methyl ether in reaction vessel, 900ml mass fraction is 20% butane solution, raise solution temperature to 40 ℃, add 4mol lead tetraacetate, and 4mol aqueous solution, control the stirring speed to 110rpm, and continue to react for 2h;

[0017] B: Then increase the temperature to 50°C, add 3mol sodium chloroplatinate powder, react for 60min, add oxalic acid solution with a mass fraction of 25%, adjust the pH to 5, lower the temperature to 10°C, let stand for 30min, and precipitate solids, use Wash with 10% potassium chloride solution for 40 minutes, wash with 70% butyl ether solution for 20 minutes, and then recrystallize in 80% 1,4-butanediol solution. Phosphorus was dehydrated to obtain 536.172 g of diketone guluronic acid with a yield of 98.2%.

Embodiment 2

[0019] The synthetic method of vitamin drug intermediate diketogulonic acid comprises the following steps:

[0020] A: Add 2mol 2,3,4,6-diketone sorbosyl methyl ether in reaction vessel, 900ml mass fraction is 23% butane solution, raise solution temperature to 43 ℃, add 5mol lead tetraacetate, and 5mol aqueous solution, control the stirring speed to 120rpm, and continue to react for 2.5h;

[0021] B: Then raise the temperature to 54°C, add 3.5mol sodium chloroplatinate powder, react for 75min, add oxalic acid solution with a mass fraction of 27.5%, adjust the pH to 5.5, lower the temperature to 12°C, let it stand for 35min, and precipitate a solid. Wash with 13% potassium chloride solution for 45 minutes, wash with 72.5% butyl ether solution for 25 minutes, then recrystallize in 83% 1,4-butanediol solution, dehydrating agent anhydrous Calcium sulfate was dehydrated to obtain 537.81 g of diketone guluronic acid with a yield of 98.5%.

Embodiment 3

[0023] The synthetic method of vitamin drug intermediate diketogulonic acid comprises the following steps:

[0024] A: Add 2mol 2,3,4,6-diketone sorbosyl methyl ether in reaction vessel, 900ml mass fraction is 26% butane solution, raise solution temperature to 46 ℃, add 6mol lead tetraacetate, and 6mol aqueous solution, control the stirring speed at 130rpm, and continue to react for 3h;

[0025] B: Then raise the temperature to 58°C, add 4mol sodium chloroplatinate powder, react for 90min, add oxalic acid solution with a mass fraction of 30%, adjust the pH to 6, lower the temperature to 14°C, let it stand for 40min, and precipitate a solid, use Wash with 16% potassium chloride solution for 50 minutes, wash with 75% butyl ether solution for 30 minutes, and then recrystallize in 86% 1,4-butanediol solution. Phosphorus was dehydrated to obtain 541.086 g of diketone guluronic acid with a yield of 99.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com