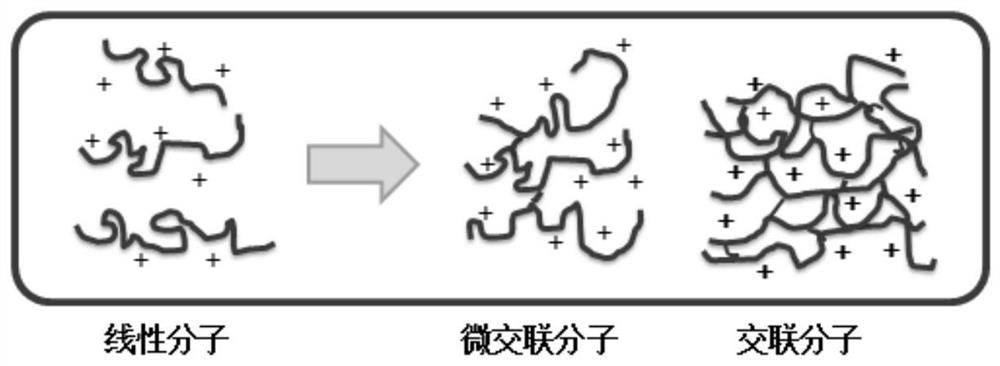

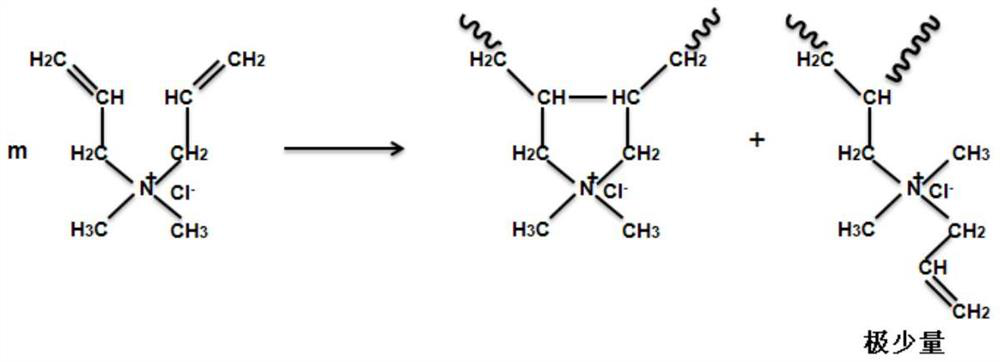

A kind of preparation method of high relative molecular mass micro-crosslinked polydimethyldiallyl ammonium chloride

A technology of dimethyl diallyl ammonium chloride and relative molecular mass, which is applied in chemical instruments and methods, runoff/rainwater treatment, water/sludge/sewage treatment, etc. Can not be used as a flocculant and other problems to achieve strong bridging performance and good stability of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Under stirring at normal temperature, 27.1 g of tetraallyl ammonium chloride (TAAC), 27.1 g of tetraallyl ammonium chloride (TAAC), 27.1 g of tetraallyl ammonium chloride (TAAC), and 27.1 g of metal ion chelating agent diethyltrimonium chloride were successively added to 42.49 kg of industrial cationic monomer DMDAAC with a mass fraction of 70.5%. Aminopentaacetic acid sodium 1.5g and deionized water 9.38kg, and stir evenly, are mixed with reaction solution;

[0029] (2) After blowing nitrogen into the reaction solution to remove oxygen, add 90 g of azobisisobutyromidine hydrochloride and 150 g of azobisisobutyronitrile, continue stirring, and heat the evenly stirred reaction solution to 45° C. until the reaction After the system becomes viscous, stop stirring and pass nitrogen, and keep warm for 3 hours;

[0030] (3) Continue to heat up to 65°C for 6 hours of heat preservation and aging reaction to obtain a slightly cross-linked PDMDAAC colloidal product with a rel...

Embodiment 2

[0032] (1) Under stirring at normal temperature, add cross-linking agent tetraallyl ammonium chloride (TAAC) 600g, metal ion chelating agent diethyltriaminepenta to 200kg mass fraction in the industrial cationic monomer DMDAAC of 60% Sodium acetate 60g and deionized water 199kg, and stir evenly, prepare reaction solution;

[0033] (2) After blowing nitrogen gas into the reaction solution to remove oxygen, add 600 g of azobisisobutyromidine hydrochloride and 1200 g of azobisisobutyronitrile, continue stirring, and heat the evenly stirred reaction solution to 50° C. until the reaction After the system becomes viscous, stop stirring and pass nitrogen, and keep warm for 6 hours;

[0034] (3) Continue to heat up to 70°C for 24 hours of heat preservation and aging reaction to obtain a slightly cross-linked PDMDAAC colloidal product with a relative molecular mass of 1.51dL / g in terms of characteristic viscosity, about 400kg, granulate the colloidal product, and dry it at 120°C Pulve...

Embodiment 3

[0036] (1) Under normal temperature stirring state, in 500kg mass fraction, add cross-linking agent tetraallyl ammonium chloride (TAAC) 3.5g, metal ion chelating agent diethyltriamine successively in the industrial cationic monomer DMDAAC of 70% 17.5g of sodium pentaacetate and 38kg of deionized water were stirred evenly to obtain a reaction solution;

[0037] (2) After blowing nitrogen into the reaction solution to remove oxygen, add 35 g of azobisisobutyromidine hydrochloride and 350 g of azobisisobutyronitrile, continue stirring, and heat the evenly stirred reaction solution to 35°C until the reaction After the system becomes viscous, stop stirring and pass nitrogen, and keep warm for 5 hours;

[0038] (3) Continue to raise the temperature to 65°C for heat preservation and aging reaction for 12 hours to obtain a slightly cross-linked PDMDAAC colloidal product with a relative molecular mass of 3.57dL / g in terms of characteristic viscosity, about 538kg, granulate the colloida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com