Material preparation method for improving DC bias characteristics and magnetic powder core preparation method

A technology of DC bias and magnetic powder core, which is applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of unspecified magnetic properties of metal soft magnetic powder cores, no obvious improvement of DC characteristics, environmental pollution, etc., and achieve convenient Large-scale industrial manufacturing, good magnetic stability, cost and pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

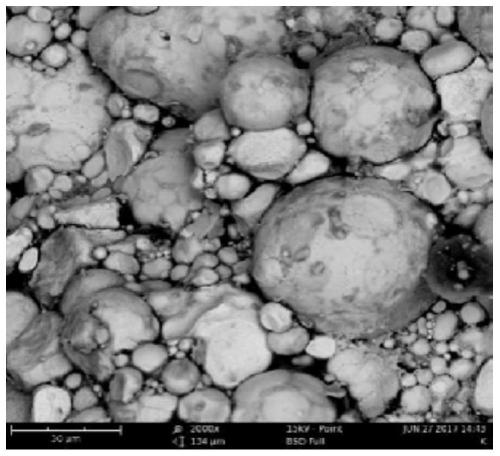

[0032] (1) sieve 700g of the first iron-silicon-aluminum magnetic powder with a 140-mesh sieve; sieve 300g of the second iron-silicon-aluminum magnetic powder with a 300-mesh sieve.

[0033] (2) Mix the two kinds of magnetic powders to obtain mixed powder, put the mixed powder into a planetary ball mill for ball milling, and the ball milling time is 35min.

[0034] (3) Insulation coating: adding nano-SiO, which accounts for 1.5% by mass of the mixed powder, to the mixed powder after ball milling 2 The powder is 15g, and an organic binder solution is also added. The organic binder selected in the organic binder solution is a silane coupling agent, and the silane coupling agent is 70g, accounting for 7% of the mass of the mixed powder; The binder disperses better, and the dispersing solvent used is 500g acetone; it will be doped with nano-SiO 2 The mixed powder with the organic binder is stirred evenly and reacted for 15 minutes to form a magnetic powder slurry. The magnetic p...

Embodiment 2

[0046] (1) sieve 750g of the first iron-silicon-aluminum magnetic powder with a 140-mesh sieve; sieve 250g of the second iron-silicon-aluminum magnetic powder with a 300-mesh sieve.

[0047] (2) Mix the two kinds of magnetic powders to obtain mixed powder, put the mixed powder into a planetary ball mill for ball milling, and the ball milling time is 25min.

[0048] (3) Insulation coating: add nano-Al which accounts for 0.5% of the mass of the mixed powder to the mixed powder after ball milling 2 O 3 Powder 5g, also add an organic binder solution, the organic binder selected in the organic binder solution is silicone resin, and the silicone resin is 50g, accounting for 5% of the mass of the mixed powder; The dispersion is better, and the dispersing solvent used is 400g acetone; it will be doped with nano-Al 2 O 3 The mixed powder with the organic binder is stirred evenly and reacted for 15 minutes to form a magnetic powder slurry. The magnetic powder slurry was heated to 60...

Embodiment 3

[0060] (1) sieve 700g of the first iron-silicon-aluminum magnetic powder with a 140-mesh sieve; sieve 300g of the second iron-silicon-aluminum magnetic powder with a 300-mesh sieve.

[0061] (2) Mix the two kinds of magnetic powders to obtain mixed powder, put the mixed powder into a planetary ball mill for ball milling, and the ball milling time is 25min.

[0062] (3) Insulation coating: adding nano-SiO, which accounts for 1.5% by mass of the mixed powder, to the mixed powder after ball milling 2 The powder is 15g, and an organic binder solution is also added. The organic binder selected in the organic binder solution is a silane coupling agent, and the silane coupling agent is 70g, accounting for 7% of the mass of the mixed powder; The binder disperses better, and the dispersing solvent used is 400g ethanol; it will be mixed with nano-SiO 2 The mixed powder with the organic binder is stirred evenly and reacted for 15 minutes to form a magnetic powder slurry. The magnetic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com