A kind of nano-vanadium-zirconium blue ceramic pigment and preparation method thereof

A technology of ceramic pigment and vanadium zirconium blue, applied in fibrous fillers and other directions, can solve the problems of complex production process and high production cost, and achieve the effects of environmental friendliness, low price and low firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

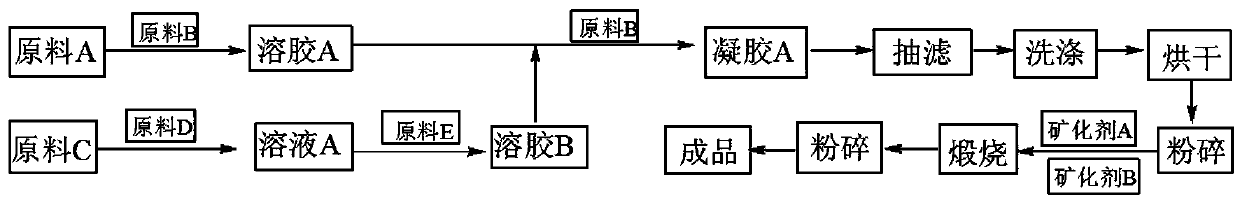

[0026] The preparation method is such as figure 1 As shown, where: raw material A is sodium silicate, raw material B is acid or weak base salt of strong acid, raw material C is vanadium pentoxide, raw material D is sodium hydroxide, raw material E is zirconium oxychloride, and mineralizer A is chlorine Sodium fluoride, mineralizer B is sodium fluoride, sol A is silicic acid sol, sol B is zirconium vanadate sol, solution A is sodium metavanadate solution, and gel A is zirconium vanadate silicate gel. Specific steps are as follows:

[0027] Step 1: Weigh the following raw materials according to the weight ratio: 8~15 parts of vanadium pentoxide, 30~50 parts of zirconium oxychloride, 30~45 parts of sodium silicate, 25~40 parts of acid or strong acid weak base salt, chlorine 1~2.5 parts of sodium fluoride, 1~2.5 parts of sodium fluoride;

[0028] Step 2: Dissolve sodium silicate in water to obtain a sodium silicate solution;

[0029] Step 3: Dissolve acid or strong acid or weak base s...

Embodiment 1

[0039] A preparation method of nano vanadium zirconium blue ceramic pigment includes the following steps:

[0040] Step 1. Weigh the raw materials: 8g vanadium pentoxide, 30g zirconium oxychloride, 33g sodium silicate, 25g ammonium chloride, 1g sodium chloride, 1g sodium fluoride;

[0041] Step 2: Dissolve sodium silicate into 20 mL of deionized water and stir to obtain a sodium silicate solution;

[0042] Step 3. Dissolve ammonium chloride in deionized water and prepare it to 5 mol.L -1 Solution

[0043] Step 4. Put the sodium silicate solution prepared in step 2 into a 200mL beaker, and add 1 to 2 drops of phenolphthalein solution in it, and add the ammonium chloride solution prepared in step 3 drop by drop, and stir while dropping. When the dripping happens to disappear, stop the dripping and continue to stir to obtain a uniform and transparent silicate sol;

[0044] Step 5. Dissolve zirconium oxychloride in 20 mL of deionized water and stir to obtain a zirconium oxychloride solutio...

Embodiment 2

[0052] A preparation method of nano vanadium zirconium blue ceramic pigment includes the following steps:

[0053] Step 1. Weigh the raw materials: 10g vanadium pentoxide, 37g zirconium oxychloride, 37g sodium silicate, 35g ammonium chloride, 1.5g sodium chloride, 1.5g sodium fluoride;

[0054] Step 2: Dissolve sodium silicate into 20 mL of deionized water and stir to obtain a sodium silicate solution;

[0055] Step 3. Dissolve ammonium chloride in deionized water and prepare it to 5 mol.L -1 Solution

[0056] Step 4. Put the sodium silicate solution prepared in step 2 into a 200mL beaker, and add 1 to 2 drops of phenolphthalein solution in it, and add the ammonium chloride solution prepared in step 3 drop by drop, and stir while dropping. When the dripping happens to disappear, stop the dripping and continue to stir to obtain a uniform and transparent silicate sol;

[0057] Step 5. Dissolve zirconium oxychloride in 20 mL of deionized water and stir to obtain a zirconium oxychloride so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com