A kind of microcapsule gel breaker and its preparation method and application

A technology of gel breaker and microcapsule, applied in the field of microcapsule gel breaker and its preparation, can solve the problems of high price of ethyl cellulose, unfavorable large-scale promotion, high equipment requirements and the like, and achieves high sphericity and good processing. Performance, the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) At room temperature (25° C.), add 1.0 g of ABS to a three-necked flask pre-filled with 30 mL of dichloromethane, and stir thoroughly to obtain a polymer solution.

[0052] 2) Weigh 0.5 g of ammonium persulfate powder and add it to the polymer solution at a stirring rate of 450 rpm to uniformly disperse the ammonium persulfate powder to obtain a dispersion.

[0053] 3) Under the condition that the stirring speed is maintained at about 300 rpm, a total of about 20 mL of polydimethylsiloxane with a viscosity of 3000 cSt is slowly added dropwise to the above dispersion to obtain a mixture.

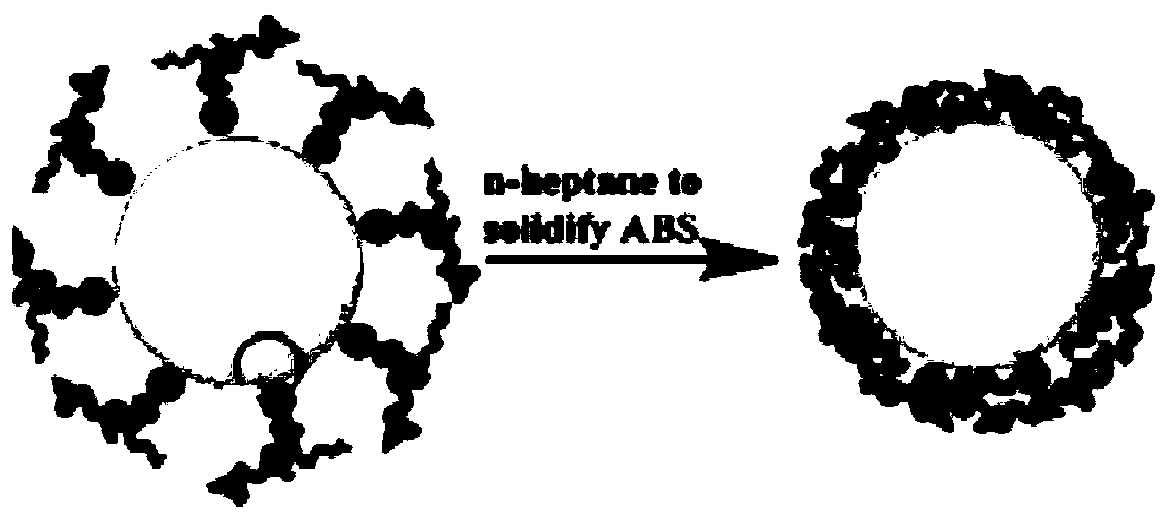

[0054] 4) Pour the mixture quickly into a round-bottomed three-necked flask pre-filled with 250mL n-heptane and equipped with a condensation device, and stir for about 30 minutes at a stirring rate of 450 rpm. It can be observed that solid particles are separated out and gradually dispersed completely. Dispersion system.

[0055] 5) Heat the above-mentioned dispersion system and heat it at 4...

Embodiment 2~3

[0059] The methods for preparing microcapsule breakers in Examples 2 to 3 are basically the same as Example 1, except that the viscosity of the polydimethylsiloxane used in step 3) is 1000 cSt and 5000 cSt, respectively.

Embodiment 4~5

[0061] The methods for preparing microcapsule breakers in Examples 4 to 5 are basically the same as in Example 1, except that the masses of ABS used in step 1) are 0.8 g and 1.25 g, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com