Soft capsules for treating sow postpartum endometritis and preparation method thereof

A technology for endometritis and soft capsules, applied in capsule delivery, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problem of failure to achieve sustained release, reinjection of air or warm water , poor redispersibility and other problems, to achieve the effect of saving manpower and material resources, short melting time limit and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

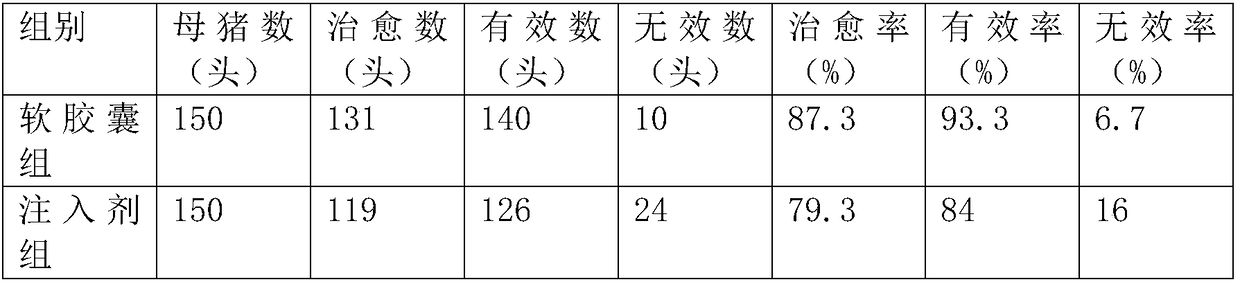

Examples

Embodiment 1

[0021] A preparation method for soft capsules for treating postpartum endometritis in sows, the steps are as follows:

[0022] (1) Get 3700g polyethylene glycol 400 (92.5wt%), 80g propylene glycol (2wt%) and 120g glycerol (3wt%), stir and mix evenly, heat to 70 ℃, then add 100g chlorhexidine acetate (2.5wt%) %), stirred until completely dissolved, and filtered to obtain the water-soluble part containing chlorhexidine acetate. Weighed 700g of the volatile oil (70wt%) of Scutellaria chinensis, mixed with 200g of water (20wt%), and 100g of polyoxyethylene lauryl ether 58 (10wt%) to obtain the volatile oil part. At a temperature of 30°C and a stirring speed of 3000r / min, the volatile oil part was added to the solution of the water-soluble part to obtain a clear and transparent microemulsion.

[0023] (2) Take 100 parts of gelatin, 90 parts of purified water, 8 parts of PEG400 and 50 parts of glycerin. Put glycerin, purified water, and PEG400 into the plastic tank, stir and heat ...

Embodiment 2

[0026] A preparation method for soft capsules for treating postpartum endometritis in sows, the steps are as follows:

[0027] (1) Get 3100g polyethylene glycol 400 (77.5wt%), 200g propylene glycol (5wt%) and 200g glycerin (5wt%), stir and mix evenly, heat to 70 ℃, then add 500g chlorhexidine acetate (12.5wt%) %), stirred until completely dissolved, and filtered to obtain the water-soluble part containing chlorhexidine acetate. The volatile oil fraction was obtained by weighing 700 g of volatile oil (70 wt %) of Echinacea chinensis, 200 g of water (20 wt %), and 100 g of polyoxyethylene lauryl ether 58 (10 wt %) and mixing them uniformly. At a temperature of 30°C and a stirring speed of 3000r / min, the volatile oil part was added to the solution of the water-soluble part to obtain a clear and transparent microemulsion.

[0028] (2) Take 50 parts of gelatin, 50 parts of gum arabic, 90 parts of purified water, 5 parts of PEG400, 30 parts of glycerin, 10 parts of propylene glycol...

Embodiment 3

[0031] A preparation method for soft capsules for treating postpartum endometritis in sows, the steps are as follows:

[0032] (1) Get 2640g polyethylene glycol 400 (66wt%), 360g propylene glycol (9wt%), stir and mix evenly, be heated to 70 ℃, then add 1000g chlorhexidine acetate (25wt%), stir until dissolving completely, filter A water-soluble fraction containing chlorhexidine acetate was obtained. The volatile oil fraction was obtained by weighing 700 g of volatile oil (70 wt %) of Echinacea chinensis, 200 g of water (20 wt %), and 100 g of polyoxyethylene lauryl ether 58 (10 wt %) and mixing them uniformly. At a temperature of 30°C and a stirring speed of 3000r / min, the volatile oil part was added to the solution of the water-soluble part to obtain a clear and transparent microemulsion.

[0033] (2) Take 100 parts of gelatin, 100 parts of water, 3 parts of PEG400 and 40 parts of glycerin. Other operations were the same as in Preparation Example 1.

[0034] (3) Adopt full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com