Preparation method of manganese-carrying modified corncob activated carbon used for removing aniline in water body high efficiently

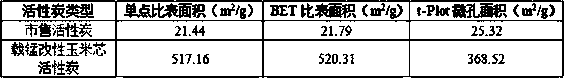

A technology of corn cob and activated carbon, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of complex process, high treatment cost, secondary pollution, etc., achieve good selective adsorption, improve removal High efficiency and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

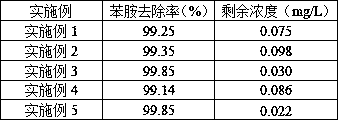

Examples

Embodiment 1

[0020] Preparation of manganese-loaded modified corn cob activated carbon. Take 10 g of corncobs, according to the mass ratio of corncobs and phosphoric acid of 1:0.5, mix the corncob powder and phosphoric acid solid evenly, then add 2 mL of 2% boric acid, impregnate the corncob powder, and then roast at 350 °C After 15 minutes, cool and grind to obtain corn-based activated carbon. The obtained corn-based activated carbon is soaked in hydrochloric acid with a mass concentration of 10% for 2 to 3 hours, filtered, rinsed with distilled water until the pH value of the rinse water is neutral, dried and ground to obtain activated corncob activated carbon. Then, the prepared activated corn cob activated carbon was added to 50 mL of potassium permanganate solution with a concentration of 0.04 mol / L, stirred for 24 h at a speed of 100 r / min, modified by manganese doping, filtered, At a calcination temperature of 400 ℃, the solid product was calcined for 1 h, and then ground to obtain...

Embodiment 2

[0023] Preparation of manganese-loaded modified corn cob activated carbon. Take 10 g of corncobs, according to the mass ratio of corncobs and phosphoric acid of 1:1, mix the corncob powder and phosphoric acid solid evenly, then add 4 mL of 8% boric acid, impregnate the corncob powder, and then roast at 400 °C After 30 minutes, cool and grind to obtain corn-based activated carbon. The obtained corncob activated carbon is soaked in hydrochloric acid with a mass concentration of 5% for 2 to 3 hours, filtered, rinsed with distilled water until the pH value of the rinse water is neutral, dried and ground to obtain activated corncob activated carbon. Then, the prepared activated corn cob activated carbon was added to 50 mL of potassium permanganate solution with a concentration of 0.05 mol / L, stirred for 22 h at a speed of 150 r / min, modified by manganese doping, filtered, At a calcination temperature of 450 °C, the solid product was calcined for 2 h, and then ground to obtain the ...

Embodiment 3

[0026] Preparation of manganese-loaded modified corn cob activated carbon. Take 10 g of corncobs, according to the mass ratio of corncobs and phosphoric acid of 1:2, mix the corncob powder and phosphoric acid solid evenly, then add 10 mL of 5% boric acid, impregnate the corncob powder, and then roast at 450 °C After 60 minutes, cool and grind to obtain corn-based activated carbon. The obtained corncob activated carbon is soaked in hydrochloric acid with a mass concentration of 5% for 2 to 3 hours, filtered and rinsed with distilled water until the pH value of the rinse water is neutral, dried and ground to obtain activated corncob activated carbon. Then, the prepared activated corn cob activated carbon was added to 50 mL of potassium permanganate solution with a concentration of 0.05 mol / L, stirred for 20 h at a speed of 200 r / min, modified by manganese doping, filtered, At a calcination temperature of 450 °C, the solid product was calcined for 1 h, and then ground to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com