Method for preparing farming soil remediation agent based on PAL-M material and plant residues

A technology of soil remediation agent and plant residue, applied in the field of functional soil remediation agent, can solve the problems such as the complicated preparation process of modified PAL materials, achieve the effect of improving adsorption capacity and increasing repairing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

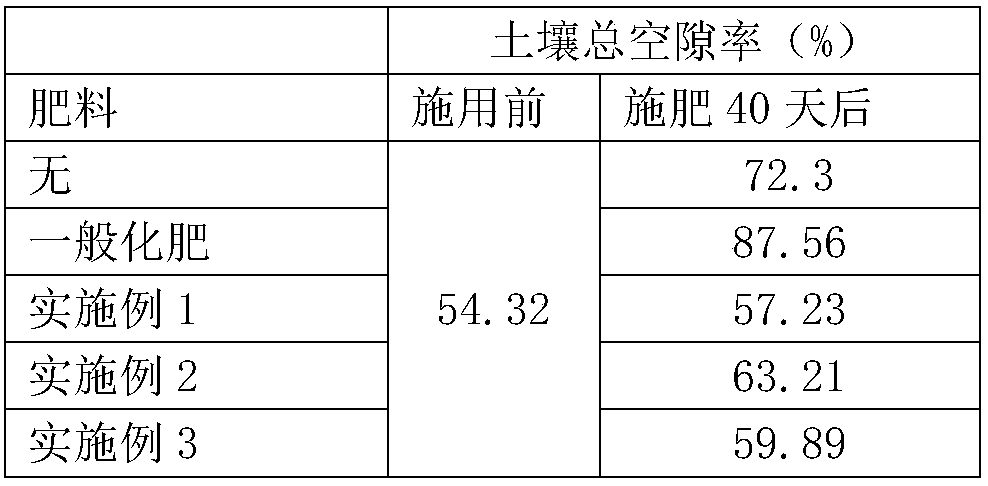

Examples

Embodiment 1

[0022] A kind of method for preparing agricultural soil remediation agent based on PAL-M material and plant residue, the concrete steps of preparation are as follows:

[0023] 1) Stir and mix the PAL powder with a particle size of 300 mesh and a NaOH solution with a concentration of 2mol / L and a volume 0.5 times the volume of the PAL powder, and then ultrasonically treat the mixed alkaline PAL powder at a power of 350w and a frequency of 40Hz for 45min. Wash the PAL powder to neutrality, and then dry it at 150°C, which is conducive to the opening and formation of the internal cavity of the PAL powder and the removal of impurities in the PAL powder, and then the pretreated PAL powder, silane coupling agent, polyvinylpyrrolidone and Thiourea is mixed evenly in a mass ratio of 1:0.15:0.06:0.6, then ultrasonically reacted for 100min at a power of 350w and a frequency of 40Hz, and the PAL-M material prepared by ultrasonic inversion, wherein the selected silane coupling agent is made...

Embodiment 2

[0027] This embodiment is the same as Example 1, except that the parts by weight of PAL-M material, activated sludge, plant residue, gelatin and EM bacteria in this embodiment are 30 parts of PAL-M material, 25 parts of activated sludge, 15 parts of plant residue, 8 parts of gelatin and 1 part of EM bacteria.

Embodiment 3

[0029] This embodiment is the same as Example 1, except that the parts by weight of PAL-M material, activated sludge, plant residue, gelatin and EM bacteria in this embodiment are 45 parts of PAL-M material, 15 parts of activated sludge, 15 parts of plant residues, 5 parts of gelatin and 3 parts of EM bacteria.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com