Metal catalyst compound and preparation method thereof

A technology of metal catalysts and composites, applied in the field of metal catalyst composites and their preparation, can solve problems such as low catalytic efficiency and high-temperature sintering, and achieve the effects of reducing specific surface area, increasing porosity, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

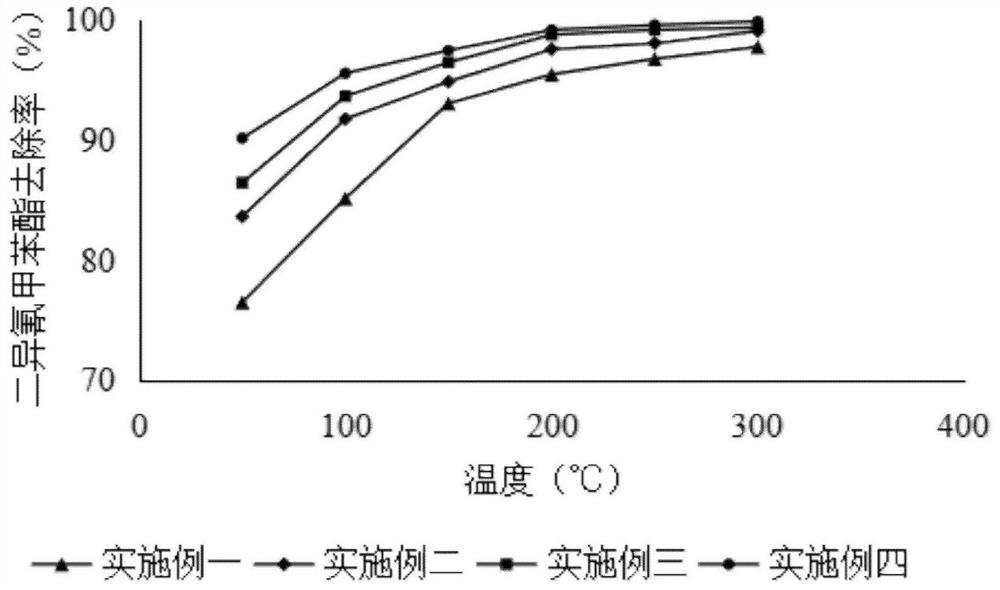

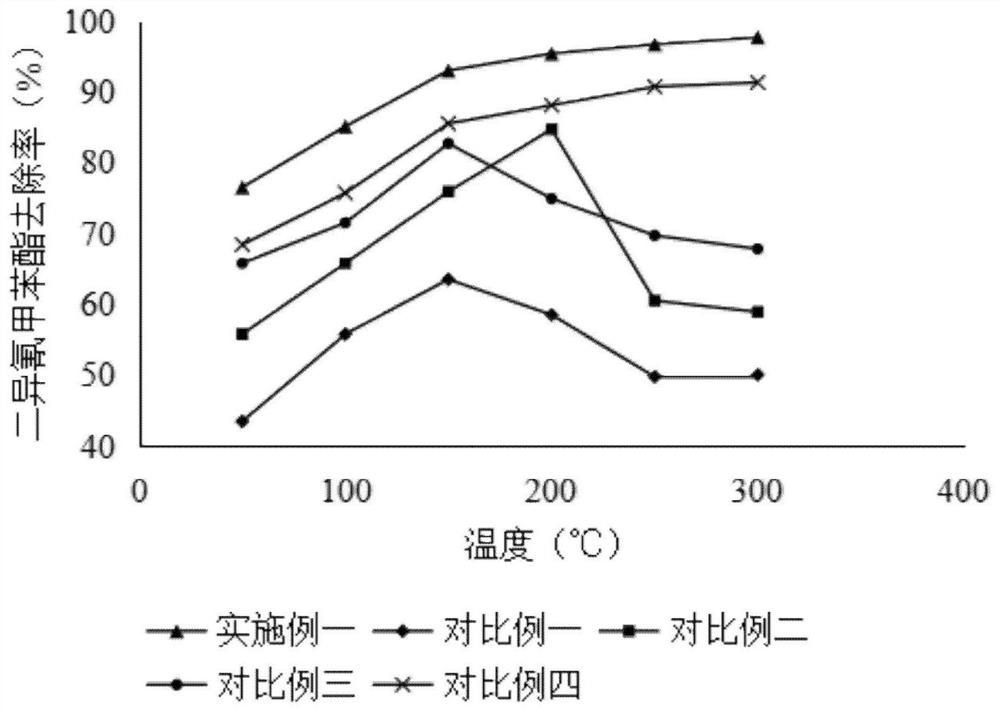

Embodiment 1

[0019] In the metal catalyst composite of this embodiment, the carrier of the catalyst is modified γ-Al 2 O 3 , the active components are manganese nitrate tetrahydrate, cerium nitrate hexahydrate, copper nitrate and yttrium nitrate hexahydrate.

[0020] Modified γ-Al 2 O 3 The preparation method is as follows: the γ-Al 2 O 3 Immersion in nitric acid, γ-Al 2 O 3 The mass concentration in nitric acid is 10%; then add lanthanum nitrate, chlorinated paraffin, cellulose and citric acid in proportion, stir evenly, let stand for 1 hour to form a gel, and then extrude into granules at a constant temperature of 130 ° C and 10 MPa , and then carbonized at 300 °C to obtain modified γ-Al 2 O 3 . where γ-Al 2 O 3 : The mass ratio of lanthanum nitrate: chlorinated paraffin: cellulose: citric acid was 10:2:1:3:2.

[0021] The preparation method of the metal catalyst composite comprises the following steps: dissolving manganese nitrate tetrahydrate, cerium nitrate hexahydrate, co...

Embodiment 2

[0023] In the metal catalyst composite of this embodiment, the carrier of the catalyst is modified γ-Al 2 O 3 , the active components are manganese nitrate tetrahydrate, cerium nitrate hexahydrate, copper nitrate and yttrium nitrate hexahydrate.

[0024] Modified γ-Al 2 O 3 The preparation method is as follows: the γ-Al 2 O 3 Immersion in nitric acid, γ-Al 2 O 3 The mass concentration in nitric acid is 12%; then add lanthanum nitrate, chlorinated paraffin, cellulose and citric acid according to the proportion, stir evenly, let stand for 1.5 hours to form a gel, and then extrude it at a constant temperature of 140 ° C and 15 MPa. Granular, and then carbonized at 300 °C to obtain modified γ-Al 2 O 3 . γ-Al 2 O 3 : The mass ratio of lanthanum nitrate: chlorinated paraffin: cellulose: citric acid is 11:3:1.5:4:2.5.

[0025] The preparation method of the metal catalyst composite comprises the following steps: dissolving manganese nitrate tetrahydrate, cerium nitrate hex...

Embodiment 3

[0027] In the metal catalyst composite of this embodiment, the carrier of the catalyst is modified γ-Al 2 O 3 , the active components are manganese nitrate tetrahydrate, cerium nitrate hexahydrate, copper nitrate and yttrium nitrate hexahydrate.

[0028] Modified γ-Al 2 O 3 The preparation method is as follows: the γ-Al 2 O 3 Immersion in nitric acid, γ-Al 2 O 3 The mass concentration in nitric acid is 14%; then add lanthanum nitrate, chlorinated paraffin, cellulose and citric acid according to the proportion, stir evenly, let stand for 2 hours to form gel, and then extrude into granules at a constant temperature of 145 ° C and 15 MPa , and then carbonized at 500 °C to obtain modified γ-Al 2 O 3 . γ-Al 2 O3 : The mass ratio of lanthanum nitrate: chlorinated paraffin: cellulose: citric acid is 13:4:2:4.5:3.

[0029] The preparation method of the metal catalyst composite comprises the following steps: dissolving manganese nitrate tetrahydrate, cerium nitrate hexahydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com