Lithium iron phosphate composite positive electrode sheet and preparation method thereof

A technology of lithium iron phosphate and composite positive electrodes, which is applied in the direction of phosphate, phosphorus oxyacids, phosphorus compounds, etc., can solve the problems of low electrolyte permeability, affecting cycle performance, and high density of aluminum materials, and achieves improved liquid absorption and retention Liquid capacity, good cycle performance, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

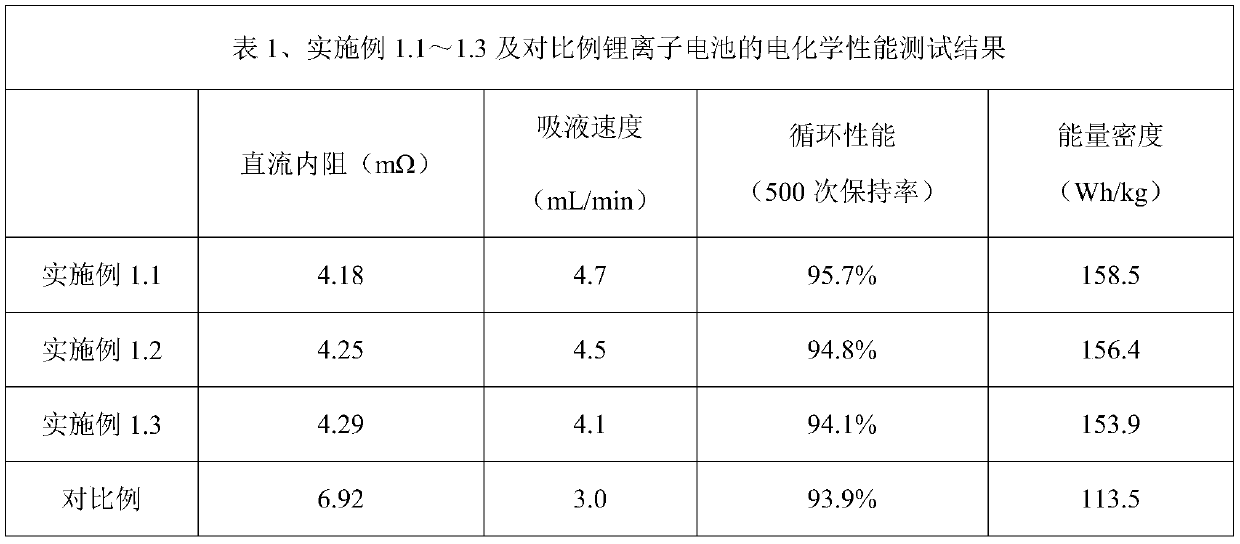

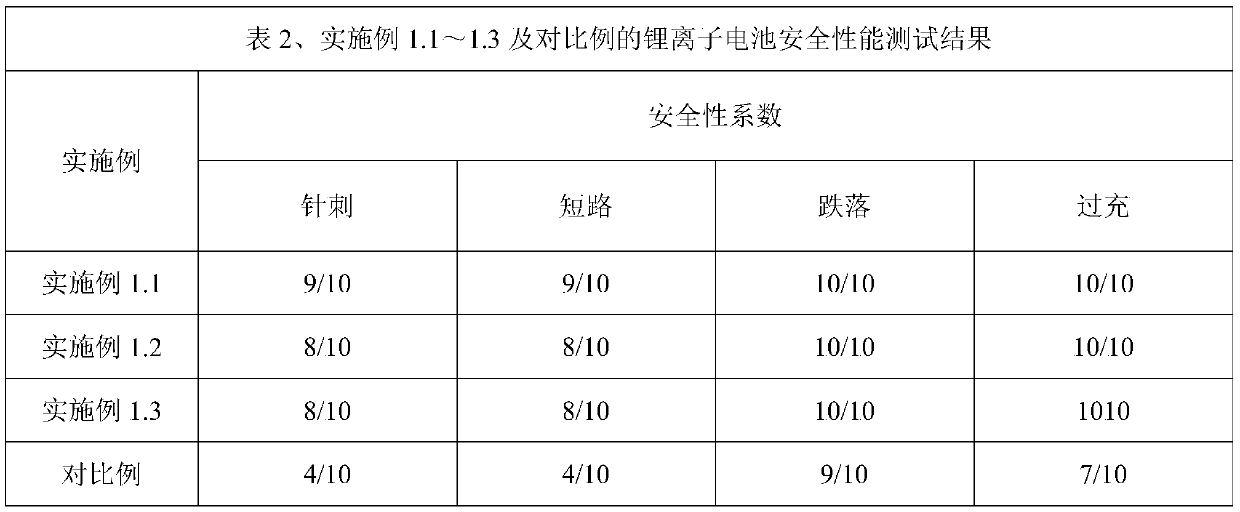

Examples

Embodiment 1

[0025] This example relates to the preparation of a lithium iron phosphate composite positive electrode sheet.

Embodiment 11

[0027] Prepare lithium iron phosphate composite positive pole sheet according to the following steps:

[0028] a. Preparation of lithium iron phosphate pole piece:

[0029] Configure lithium iron phosphate slurry, take 93g of lithium iron phosphate, 1.5g of carbon nanotubes, and 5.5g of polyvinylidene fluoride, add them to 150g of N-methylpyrrolidone, and disperse them evenly in a mixer, then vacuumize and remove foam to obtain iron phosphate Lithium slurry; the lithium iron phosphate slurry is coated on the foamed aluminum current collector (the thickness of the foamed aluminum is 20 μm, and the porosity is 90%) by a coating machine, double-sided coating, the thickness of both sides is 200 μm, after drying Rolling under a pressure of 20Mpa to obtain a lithium iron phosphate pole piece;

[0030] b. Preparation of lithium iron phosphate composite positive electrode sheet:

[0031] Take 17g (0.1mol) of silver nitrate, add it to 1000ml deionized water, configure a silver nitrat...

Embodiment 12

[0033] Prepare lithium iron phosphate composite positive pole sheet according to the following steps:

[0034] a. Preparation of lithium iron phosphate pole piece:

[0035] Configure lithium iron phosphate slurry, take 90g of lithium iron phosphate, 2g of carbon nanotubes, and 5g of polyvinylidene fluoride, add them to 150g of N-methylpyrrolidone, disperse evenly in a mixer, and then vacuumize to remove bubbles to obtain lithium iron phosphate Slurry: the lithium iron phosphate slurry is coated on the foamed nickel current collector (the thickness of the foamed aluminum is 15 μ m, and the porosity is 80%) by a coating machine, double-sided coating, the double-sided thickness is 200 μ m, after drying Rolling under a pressure of 20Mpa to obtain lithium iron phosphate pole pieces;

[0036] b. Preparation of lithium iron phosphate composite positive electrode sheet:

[0037] Take 17g (0.1mol) of silver nitrate, add it to 5000ml deionized water, configure a silver nitrate solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com