Growth promoting flora for improving waste gas treatment efficiency and waste gas treatment method

A waste gas treatment and waste gas treatment device technology, which is applied in separation methods, chemical instruments and methods, and air quality improvement, can solve the problems of low waste gas treatment efficiency and insufficient purification degree, and achieve energy consumption reduction, strong affinity, and water saving resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

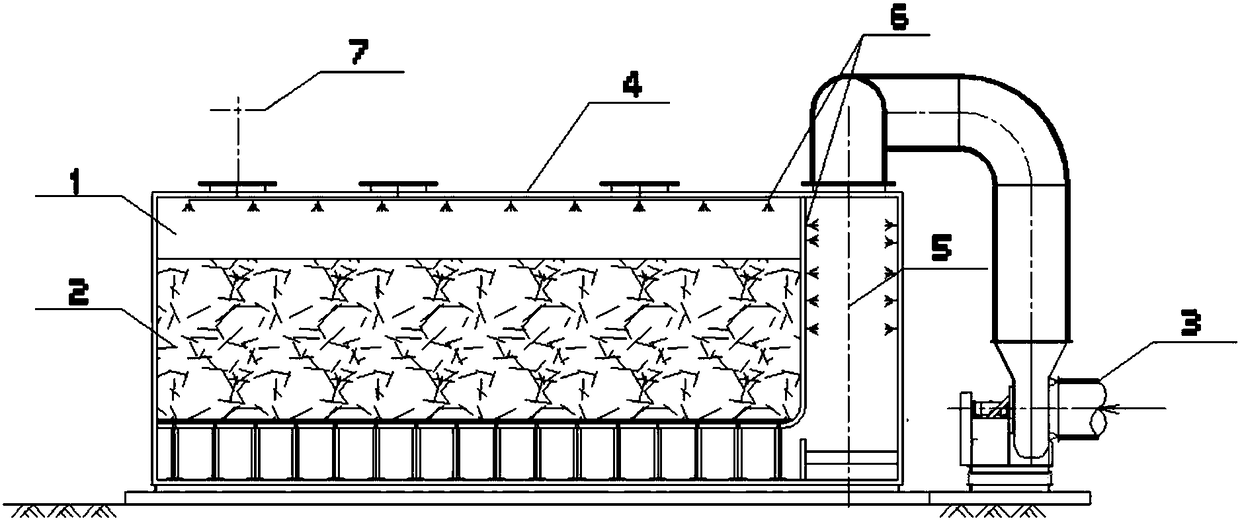

Image

Examples

Embodiment 1

[0048] Embodiment 1. Preparation of growth-promoting flora

[0049] Bifidobacteria, lactic acid bacteria, actinomycetes and colloidal bacillus were evenly mixed according to the following mass ratios to obtain growth-promoting flora.

[0050] Growth-promoting flora No. 1:

[0051] The mass ratio of bifidobacteria, lactic acid bacteria, actinomycetes and glial bacillus is 1:1:1:3.

[0052] Growth-promoting flora No. 2:

[0053] The mass ratio of bifidobacteria, lactic acid bacteria, actinomycetes and glial bacillus is 1.1:0.8:1.1:2.7.

[0054] Growth-promoting flora No. 3:

[0055] The mass ratio of bifidobacteria, lactic acid bacteria, actinomycetes and glial bacillus is 0.9:1.0:0.9:3.5.

Embodiment 2

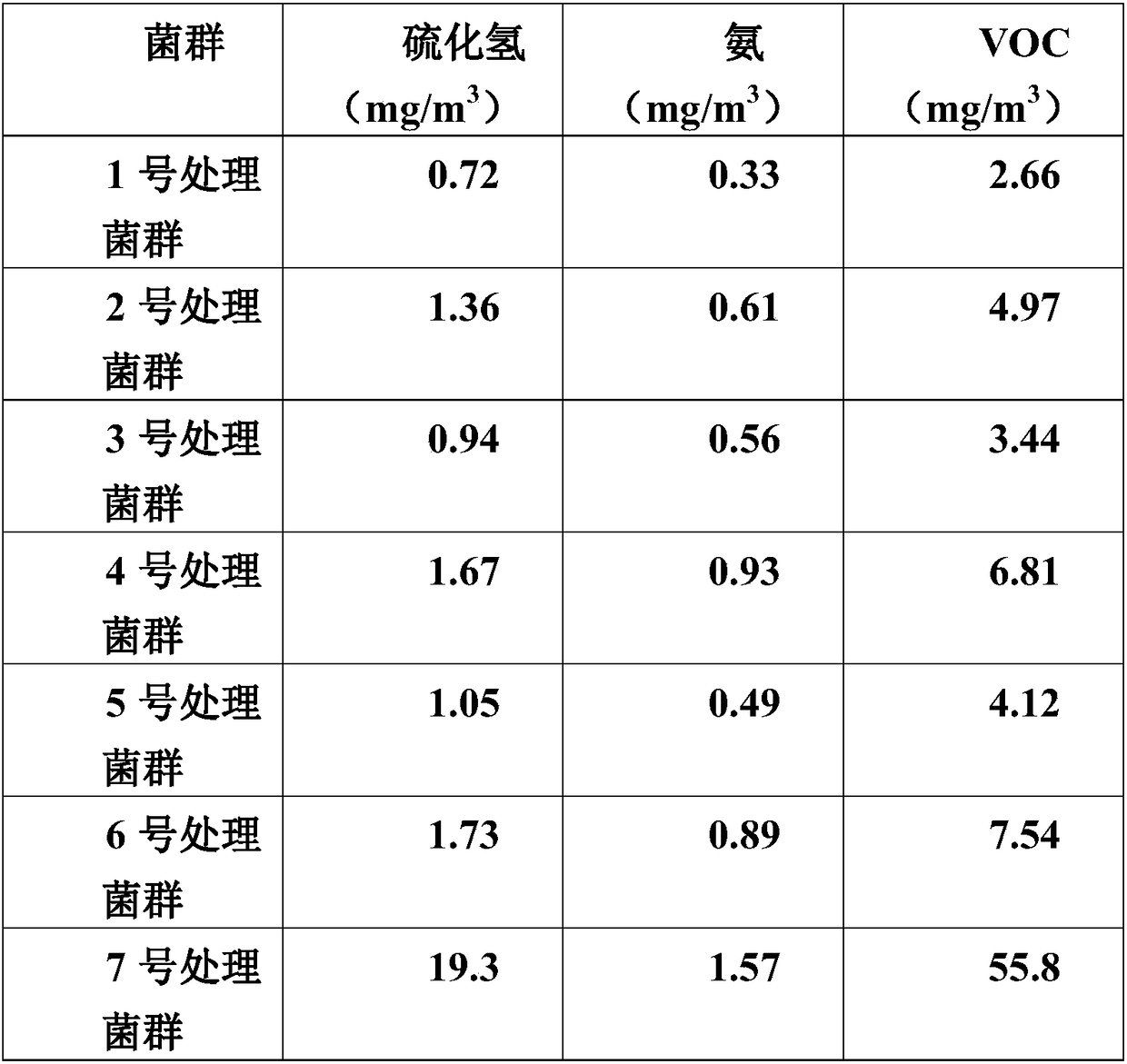

[0056] Example 2. Validation of the effect of growth-promoting bacteria on improving the efficiency of waste gas treatment

[0057] 1. Bacteria preparation for waste gas treatment

[0058] (1) Screen the mixture of target flora

[0059] a. Collect 10g of humus soil samples near a chemical plant, mix with 100ml of sterile industrial sewage with a pH of 4-7 from the plant, incubate at 30-45°C, 150r / min for 48h, and then take it out.

[0060] b. Inoculate 10ml of culture solution into 90ml of fresh sterile industrial sewage in the ultra-clean workbench, incubate at 30-45°C, 150r / min for 48 hours, then take it out. The above operation was repeated three times to enrich microorganisms that degrade volatile organic compounds.

[0061] d. Use a sterile pipette to draw 1ml of the enriched bacterial solution, put it into a test tube filled with 9ml of sterile water, shake it evenly, take 1ml of the diluted bacterial solution and mix it with another 9ml of sterile water to dilute, Re...

Embodiment 3

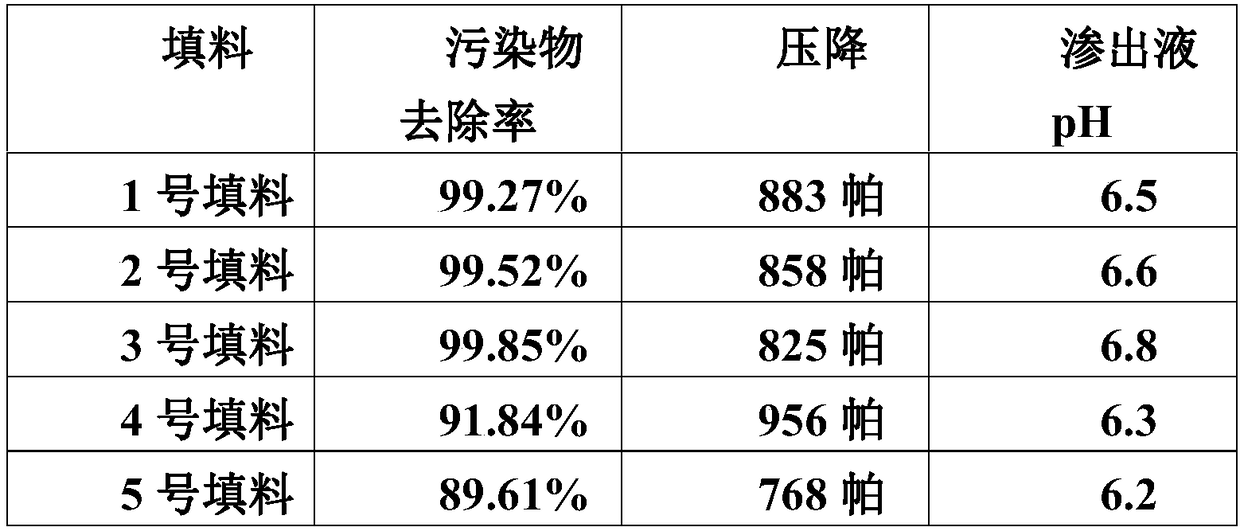

[0103] Example 3. Effect of packing on waste gas treatment efficiency

[0104] 1. Prepare the stuffing

[0105] From volcanic rock, wood blocks, and raw shells, make the stuffing as follows.

[0106] Packing No. 1

[0107] Treatment of volcanic rocks: pickling in pH6 nitric acid solution for 3 minutes, washing with water, and air-drying; then washing with alkali in pH8 sodium hydroxide solution for 3 minutes, then washing with water, and air-drying; Fumigate the volcanic rocks in the high-pressure steam for 2 minutes to remove the residual salt substances on the surface of the volcanic rocks, and screen the volcanic rock particles with a particle size of 10-20 mm and a porosity of 50%.

[0108] Wood block processing: mechanically crush the wood blocks (cannot be cut regularly), sieve after crushing, and select wood blocks with a particle size of 8-16cm and a thickness of 3-5cm. Then use a high-pressure punching gun to impact the wood block with a water pressure of 350Mpa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com