Synthesizing method of velpatasvir

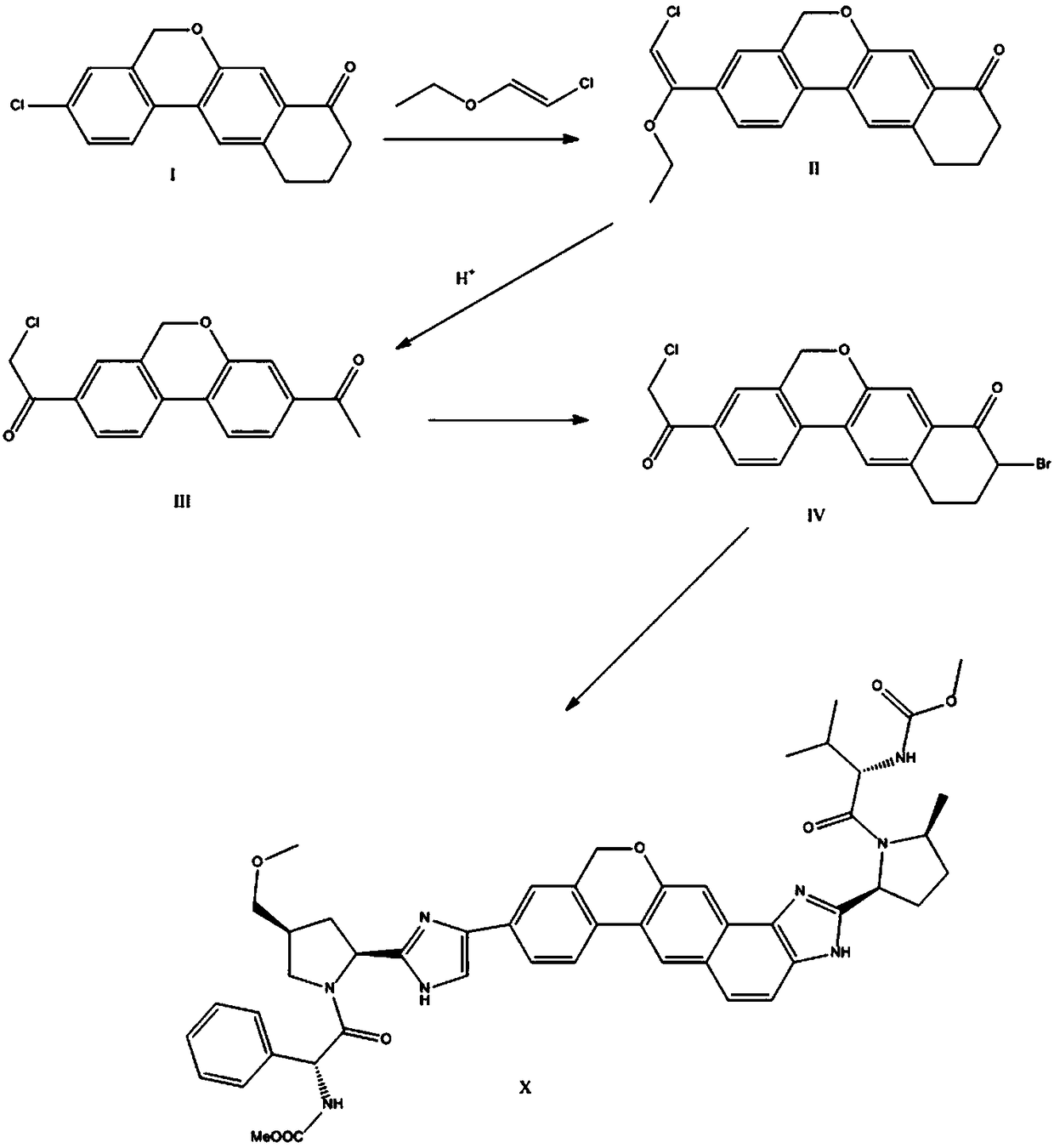

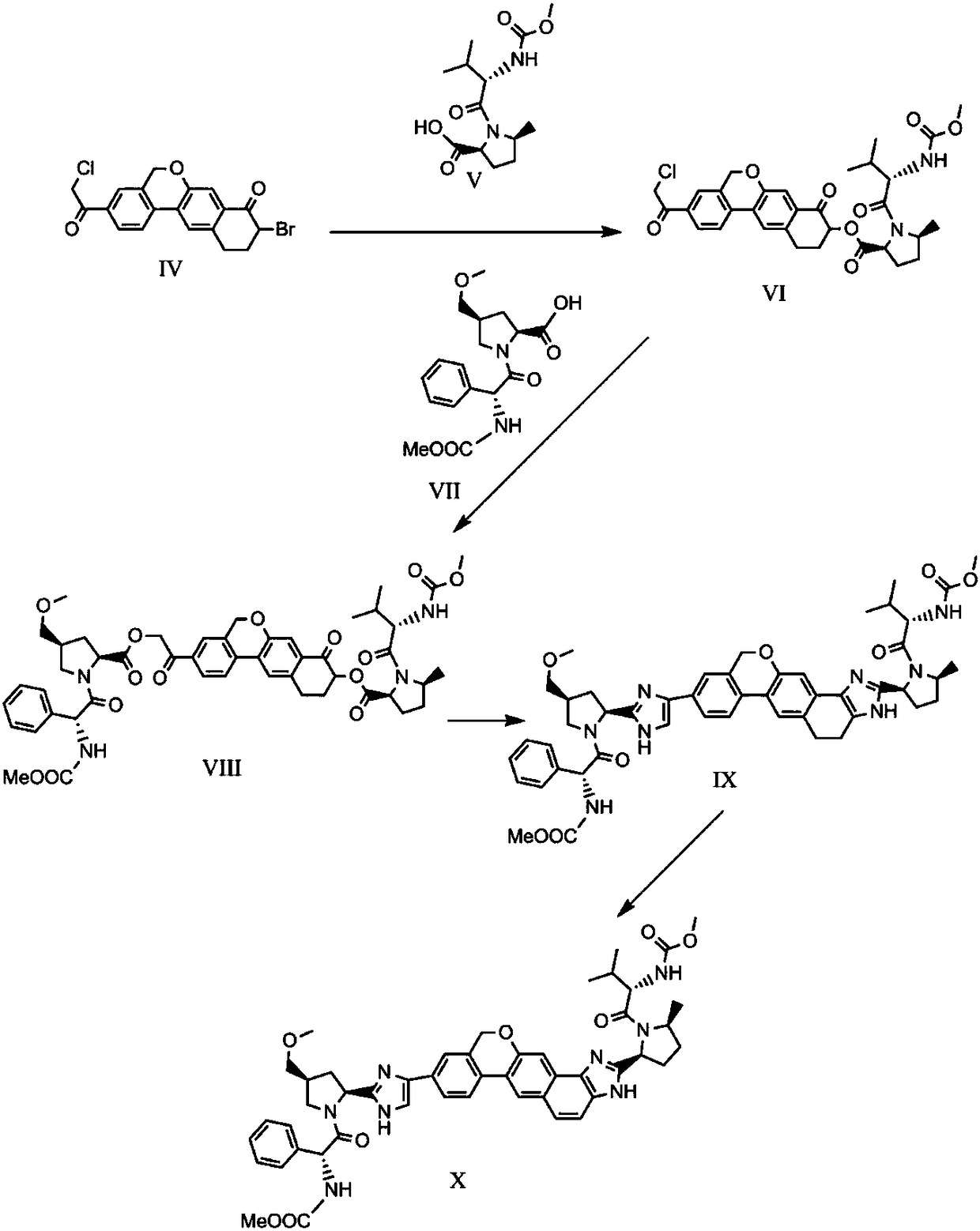

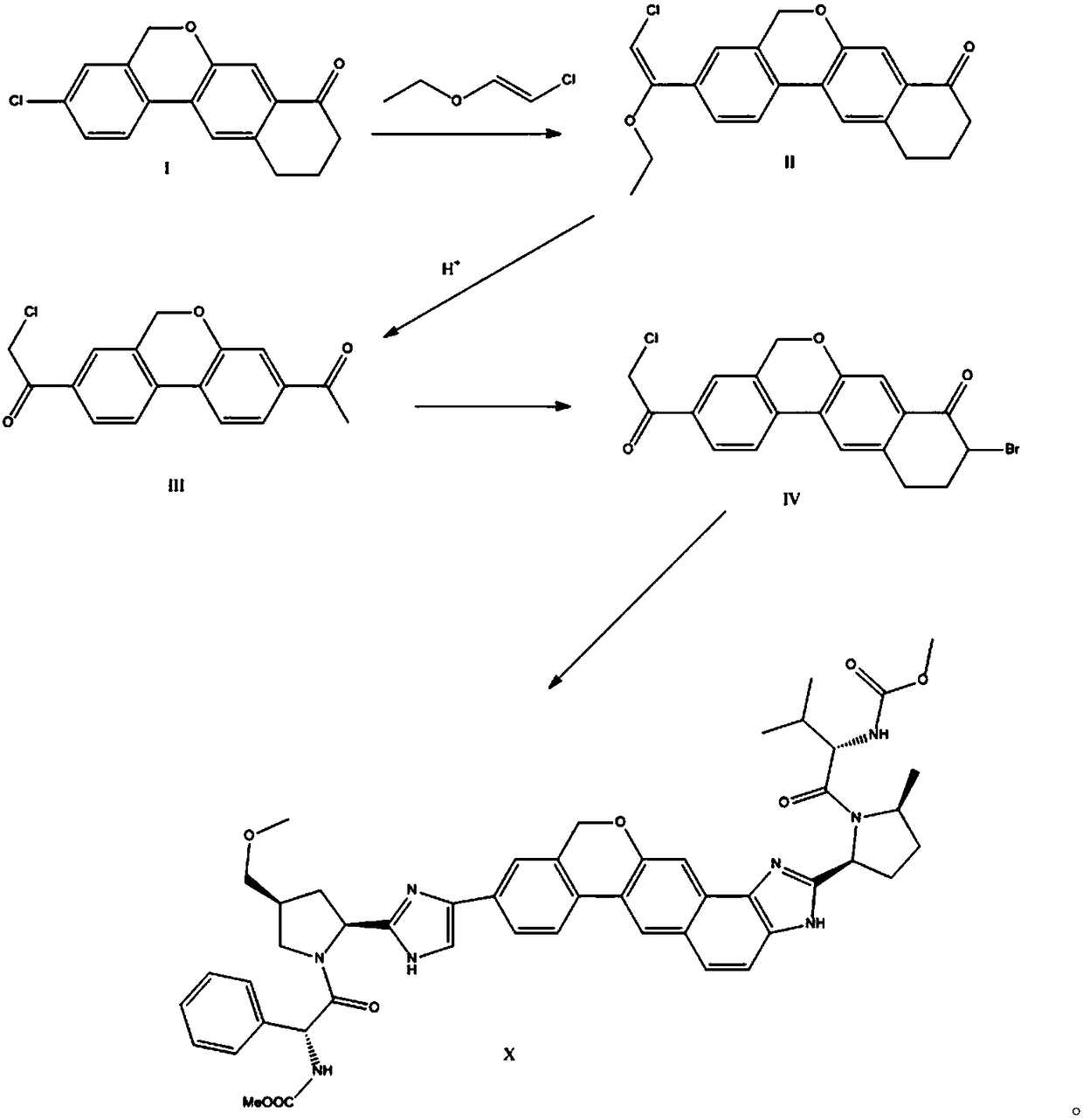

A velpatasvir and synthetic method technology, which is applied in the field of new method synthesis of the new hepatitis C virus drug velpatasvir and its series of intermediates, can solve the problem of not being suitable for industrial scale-up production, shortening reaction steps, and long reaction routes and other problems, to achieve the effect of suitability for industrialized production, low cost and high total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Preparation of Intermediate III

[0042] Take compound I (28.5g, 100mmol), 1-Cl-2-ethoxyethylene (16.0g, 150mmol), palladium acetate (1.00g, 4.5mmol), 1,3-bis(diphenylphosphine) propane ( 4.23g, 10.2mmol), potassium carbonate (20.7g, 150mmol) in 200ml of 60% THF aqueous solution, stir evenly, reflux for 2.5h, the reaction is complete, cool to room temperature, slowly add 37% concentrated hydrochloric acid 24ml, drip and stir. After the reaction was completed for 3 hours, ethyl acetate was added and extracted twice with 100 ml each time. The organic layers were combined and washed with 10% potassium carbonate aqueous solution once. The organic layer was dried with anhydrous sodium sulfate, filtered, and concentrated under reduced pressure to obtain compound III (31.2 g, 95.4%), add 90 ml of methanol and reflux at 65° C. for 10 min, slowly cool to room temperature and crystallize for 1 h, and filter to obtain compound III (30.1 g, 91.3%).

[0043] Compound III: MS(E...

Embodiment 2

[0044] Example 2 Preparation of Intermediate IV

[0045] Take compound III (19.6g, 60mmol), pyridinium tribromide (43.4g, 136mmol) and dissolve it in 150ml of 9:1 dichloromethane / methanol, under nitrogen protection, heat to 35℃, stir and react for 50min. The reaction is complete. The solution was cooled to 10°C, filtered to obtain Intermediate IV, 100ml methanol was added and refluxed at 65°C for 15min, slowly cooled to room temperature to crystallize for 2h, filtered, the filter cake was washed with 10ml methanol, and dried at 40°C to obtain Intermediate IV (20.7g, 85%).

Embodiment 3

[0046] Example 3 Synthesis of Compound VI

[0047] Compound IV (20.3 g, 50 mmol), compound V (17.2 g, 60 mmol), potassium carbonate 5.5 g, and tetrahydrofuran 150 ml were sequentially added to the reaction flask, and then reacted at 30-35° C. for 16 hours. LC monitored the disappearance of raw material IV. Add 300ml ethyl acetate, 200ml water, stir for 10min, separate the organic phase, extract the aqueous phase with ethyl acetate 100ml*3 times, combine the organic phases, dry with sodium sulfate, and concentrate to obtain compound VI (27.5g, yield 90.0%) ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com